Technical Principles and Innovative Values

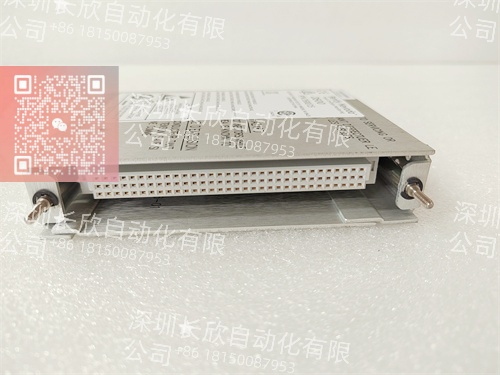

TheBently Nevada 125840-01is more than just a wire;it is an engineered component of a precision measurement system.

Innovation Point 1:Precision Matched Impedance:The cable is designed with a specific characteristic impedance to match the proximitor system.This minimizes signal reflections and attenuation,ensuring that the high-frequency signal from the probe reaches the proximitor with minimal distortion,which is critical for accurate gap measurement.

Innovation Point 2:Superior Noise Immunity:The use of triaxial or double-shielded coaxial construction provides excellent protection against electromagnetic interference(EMI)and radio frequency interference(RFI).This is essential in industrial environments filled with electrical noise from motors,drives,and switching equipment,which could otherwise corrupt the low-level sensor signal.

Innovation Point 3:Robust Environmental Protection:The cable jacket and insulation materials are selected to withstand harsh conditions,including exposure to oil,chemicals,moisture,and high temperatures commonly found near turbines,compressors,and pumps.This ensures long-term reliability and signal integrity.

Innovation Point 4:Seamless System Integration:The 11-pin connector is keyed and designed for a secure,reliable connection to the proximitor module,preventing misconnection.The pigtail end is designed for a durable,soldered,or crimped connection to the probe’s cable,which is then protected with a weatherproof seal.

Application Cases and Industry Value

Case 1:Petrochemical Plant Compressor Monitoring Upgrade:During an upgrade of a critical recycle compressor’s monitoring system,new Bently Nevada 3300 XL monitors were installed.The existing proximity probes were in good condition,but the old extension cables were replaced with newBently Nevada 125840-01cables.This replacement ensured signal integrity for the new system.The improved noise immunity of the new cables resulted in a cleaner signal and fewer spurious alarms,increasing operator confidence in the monitoring system and reducing nuisance trips.

Case 2:Paper Mill Turbine Bearing Failure Prevention:In a paper mill,a steam turbine driving a large paper machine began showing elevated vibration on a specific bearing.The signal from the proximity probe,transmitted through the125840-01cable to the monitoring system,showed a trend of increasing vibration at a frequency indicating a developing bearing defect.Because the cable provided a clean,reliable signal,the maintenance team trusted the data and scheduled a bearing replacement during a short planned outage,avoiding a catastrophic failure that would have halted the entire paper production line for days.

Related Product Combination Solutions

The125840-01cable is a vital component within a complete transducer system.Key related products include:

Proximity Probe:The sensor itself,such as the125680-01(8mm)or125730-01(11mm).

Proximitor Module:The oscillator/demodulator(e.g.,3300/45)that powers the probe and conditions the signal.

Connection Accessories:Heat-shrink tubing,silicone tape,and junction boxes for creating weatherproof splices between the probe cable and the extension cable.

Monitor Rack:The 3300 XL rack that houses the Proximitor and monitoring modules.

Calibration Kit:Tools like theTK-3for setting the initial probe gap.

Longer Extension Cables:Other standard lengths(e.g.,10m,15m)for different installation distances.

Installation,Maintenance,and Full-Cycle Support

Installation and Maintenance:Installation requires care to ensure a reliable connection.The pigtail end of the125840-01cable must be spliced to the probe’s integral cable.This connection should be soldered or crimped and then meticulously insulated and sealed with multiple layers of high-quality,oil-resistant tape and heat-shrink tubing to prevent moisture ingress,which is a common cause of signal drift.The cable should be routed away from power cables and within conduit if possible.Maintenance involves periodic visual inspection of the cable jacket for damage and checking the integrity of the connections.Monitoring the”gap voltage”or”demodulator voltage”trend in the monitoring software can help identify degradation in the cable or connections over time.

Our support for the125840-01includes providing genuine Bently Nevada cables.Our technical team can assist with compatibility verification and provide guidance on best practices for splicing and installing these critical cables to ensure long-term signal integrity.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

Leave a comment

Your email address will not be published. Required fields are marked *