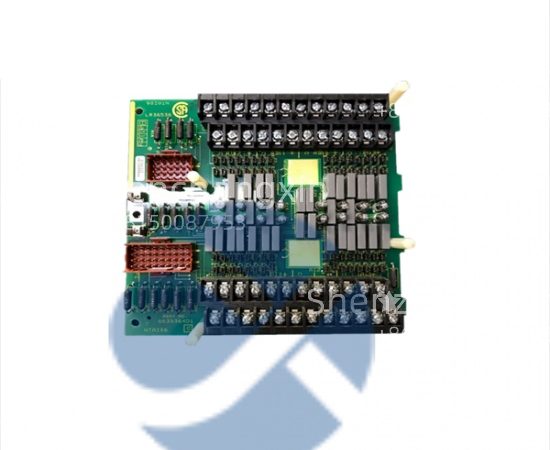

Product Overview

The ABB PM866K01 3BSE050198R1 is a high-performance controller CPU module from the ABB AC800M series. As a core component of the ABB Symphony Plus Distributed Control System (DCS), it is designed for high-load, high-reliability industrial scenarios. This module acts as the “brain” of the industrial automation control system, responsible for executing control programs, processing data, and communicating with other devices.

Main Technical Parameters

Parameter Item

Specification

Product Model

ABB PM866K01 3BSE050198R1

Processor

Dual-core ARM Cortex-A9, 800MHz

Memory Configuration

2GB RAM + 4GB eMMC Memory

Communication Interface

2×Ethernet, 2×RS232, 1×PROFIBUS DP, 2×USB3.0, 8×USB2.0

Operating Voltage

24V DC

Operating Temperature

-20°C to +60°C

Protection Rating

IP20

Mounting Method

DIN Rail Mounting

Dimensions and Weight

239×80×35mm / 0.72kg

Core Features

High-Performance Processing Capability

The PM866K01 uses a dual-core ARM Cortex-A9 processor with a clock speed of 800MHz, supporting multi-task parallel processing with a task cycle as low as 1ms. 2GB RAM ensures the ability to handle complex control algorithms and logic, supporting real-time processing of 1000+ I/O points.

Redundancy and Fault Tolerance Design

This module supports dual-controller redundancy configuration with a failover time of <10ms, ensuring zero system downtime. Built-in battery-backed RAM ensures no program loss during power outages and supports hot-swapping (I/O modules).

Multi-Protocol Communication Support

Integrates multiple industrial communication protocols, including Modbus TCP, OPC UA, and PROFIBUS DP, enabling seamless connection to third-party devices such as Siemens and Schneider Electric. Dual Gigabit Ethernet ports support PRP (Parallel Redundancy Protocol) and HSR (High Availability Seamless Ring Network).

Safety Features

Built-in fault diagnosis and emergency stop mechanisms, supporting SIL 2 safety level certification to ensure personnel and equipment safety. Full EMC certification is available, complying with IEC 61000-6-2 standards.

Application Areas

Manufacturing

In automotive manufacturing production lines, the PM866K01 is used in the welding robot control system, achieving welding accuracy down to 0.1mm, reducing the failure rate to 0.05%, and lowering annual maintenance costs by 2 million yuan.

Petrochemicals

Application of this module in catalytic cracking units enables 24-hour continuous operation through redundant design, with temperature control accuracy of ±1℃, pressure fluctuation range of ±0.5bar, and product qualification rate increased to 99.9%.

Power Energy

Integrating the PM866K01 into the SCADA system of wind farms, data from over 100 wind turbines is collected via the Modbus TCP protocol, enabling remote monitoring and fault early warning, and increasing annual power generation by 5%.

Water Treatment

Application of this module in the aeration system of wastewater treatment plants, through PID algorithm control of dissolved oxygen concentration, reduces energy consumption by 30%, sludge production by 15%, and saves 1.5 million yuan in annual operating costs.

Technical Advantages

Compatibility

The PM866K01 can directly replace the PM864 or PM865 controller in older systems. The hardware installation dimensions are the same, and only minor software upgrades are needed for operation; no complete overhaul is required.

Easy Programming and Maintenance

Utilizing Control Builder M programming software, project download, online monitoring, and fault diagnosis are all seamlessly integrated. A built-in real-time clock and battery backup ensure data integrity even after power failure, facilitating troubleshooting.

Industrial-Grade Reliability

Equipped with industrial-grade components and design standards, it can operate stably in high-temperature environments and areas with strong electromagnetic interference. With an IP20 protection rating, it is suitable for harsh industrial environments.

Installation and Maintenance

Installation Requirements

The module is mounted on a DIN rail using a standard controller rack (such as CI854). Power is supplied from the PS module via the backplane at 24VDC, ensuring stable operating voltage.

Choose Shenzhen Changxin, choose peace of mind, worry-free after-sales service. Large stock available, same-day SF Express shipping!

Leave a comment

Your email address will not be published. Required fields are marked *