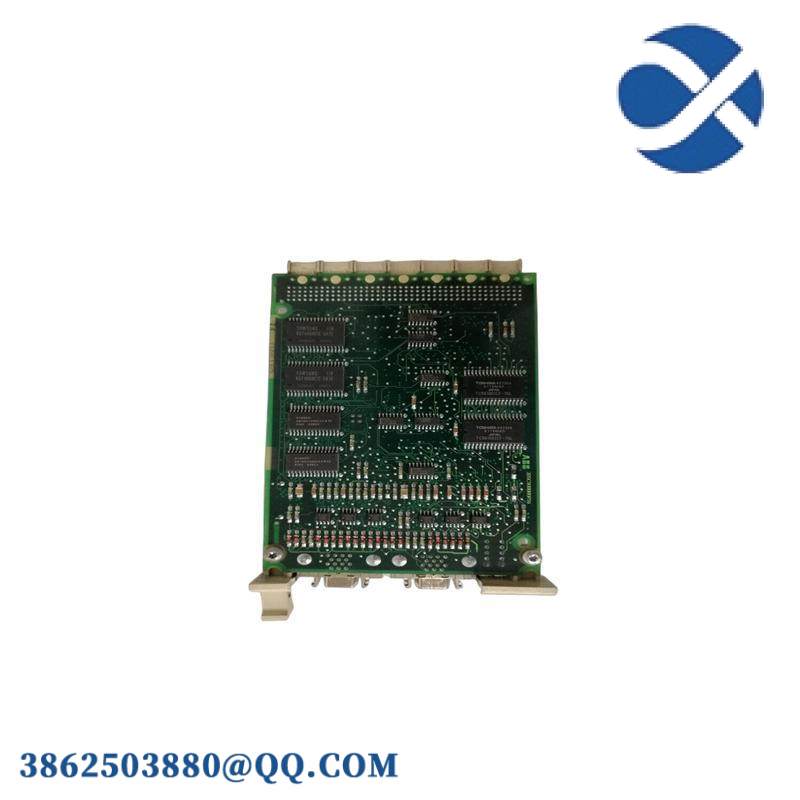

ABB CI522A 3BSE018283R1 Product Description

The ABB CI522A 3BSE018283R1 is an interface module designed to establish a robust connection between S800 I/O systems and the AF100 fieldbus. It acts as a bridge to facilitate data exchange between these two components, ensuring reliable and efficient communication in industrial automation systems.

Product Parameters

-

Model: CI522A

-

Product Code: 3BSE018283R1

-

Network Protocol: AF100

-

Power Supply: 24V DC ±20%

-

Power Consumption: Approximately 5W

-

Dimensions (L x H x W): 265mm x 27mm x 120mm

-

Net Weight: 0.2kg

-

Operating Temperature: -40°C to +85°C

Product Specifications

-

High-Precision Measurement: Ensures accurate signal conversion.

-

Fast Response: Real-time processing and transmission of analog signals.

-

Multiple Input Signal Support: Supports various input signal types, such as 0-10V and 4-20mA.

-

Modular Design: Easy to configure and expand, compatible with other modules.

-

Redundant Communication: Provides increased system reliability.

Series

The CI522A 3BSE018283R1 belongs to ABB’s S800 I/O system series, designed for industrial automation and control systems.

Features

-

High Reliability: Ensures continuous operation even in harsh industrial environments.

-

Redundant Communication Capability: Maintains system operation in case of communication link failure.

-

User-Friendly Interface: Equipped with LED status indicators for easy monitoring.

-

Supports High Data Rates: Up to 100 Mbps, ensuring fast and efficient data transmission.

-

Error Detection and Correction: Reduces the need for manual intervention to solve data-related problems.

Functions

-

Signal Management: Manages digital signals from various field devices.

-

Real-Time Monitoring: Provides real-time status updates and diagnostics.

-

System Integration: Integrates seamlessly with PLCs and DCS systems.

-

Data Conversion: Converts analog signals into digital format for processing by control systems.

Uses

The CI522A 3BSE018283R1 is widely used in:

-

Process Control: For monitoring and controlling parameters such as temperature, pressure, and flow in chemical and petrochemical industries.

-

Power Generation: For monitoring power equipment in power plants.

-

Manufacturing: For controlling production lines and machinery.

-

Building Automation: For managing HVAC and lighting systems.

Application Fields

-

Chemical Industry: For high-precision control systems.

-

Power Plants: For monitoring and controlling power equipment.

-

Food and Beverage: For maintaining hygiene and continuous production.

-

Oil and Gas: For connecting I/O devices in refineries and processing plants

Leave a comment

Your email address will not be published. Required fields are marked *