Product Overview

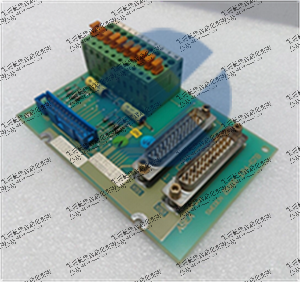

The ABB DSTD196 is a high-density digital input module designed exclusively for ABB’s AC 800M programmable logic controller(PLC)platform—an industry-leading solution for large-scale process automation and industrial control.As a core component of ABB’s Extended Automation System 800xA,the DSTD196 specializes in collecting discrete digital signals from a large number of field sensors(e.g.,limit switches,proximity sensors,safety interlocks),converting them into digital data for the AC 800M controller to execute logic commands.Its 32-channel design,SIL2 safety certification(per IEC 61508),and robust circuit architecture make it a trusted choice for applications where high sensor density,signal reliability,and space efficiency are critical.

What distinguishes the ABB DSTD196 is its balance of high channel count and advanced functionality:with 32 independent digital input channels(24V DC),it doubles the signal acquisition capacity of standard 16-channel modules(like the ABB DSTA121)while maintaining the same physical footprint—saving up to 50%of control panel space.In a large automotive assembly plant,the ABB DSTD196 replaced 16-channel modules,reducing the number of required input cards from 8 to 4 and cutting panel space usage by 40%.When paired with ABB’s Control Builder M software,the DSTD196 enables intuitive configuration of input parameters(e.g.,filter time,signal edge detection)and real-time status monitoring,eliminating the need for manual hardware adjustments.This synergy makes the ABB DSTD196 indispensable in automotive manufacturing,oil&gas,power generation,and logistics industries—where high-density sensor monitoring is foundational to process efficiency and safety.

Technical Specifications

Parameter Name

Parameter Value

Product Model

ABB DSTD196

Manufacturer

ABB Ltd.

Product Type

High-Density Digital Input Module for AC 800M PLC

Input Channels

32 independent digital input channels

Input Voltage

24V DC(19.2V DC to 30V DC operating range)

Input Current

5mA typical per channel(at 24V DC);max 10mA per channel

Response Time

≤0.5ms(adjustable via software:0.1ms to 100ms)

Safety Certification

TÜV SIL2(IEC 61508);IEC 61511 compliant for process safety

Diagnostic Features

Channel-level open/short circuit detection;overvoltage protection(up to 36V DC);module health monitoring

Communication Interface

ABB PRONETA bus(integrated with AC 800M backplane);supports hot-swap

Operating Environment

Temperature:-25°C to+60°C;Humidity:5%-95%(non-condensing);Altitude≤2000m

Protection Class

IP20(front panel);IK07 impact resistance

Physical Dimensions

100mm×160mm×25mm(W×H×D);Weight:0.4kg

Installation

DIN rail mounting(35mm);hot-swappable(no system shutdown required)

Compatibility

ABB AC 800M PLC;Control Builder M V5.1+;System 800xA V6.1+

EMI Immunity

EN 61000-6-2(industrial environment);EN 61000-6-4(emission)

MTBF(Mean Time Between Failures)

≥5.2×10⁶hours under normal operating conditions

Main Features and Advantages

32-Channel High Density for Space Efficiency:The ABB DSTD196 offers 32 discrete input channels in a standard 100×160mm form factor—equivalent to two 16-channel modules but with 50%less panel space.A logistics warehouse used the DSTD196 to monitor 32 conveyor belt proximity sensors(tracking package position)via a single module,reducing the number of required DIN rail slots from 4 to 2 and simplifying wiring(fewer power connections and bus cables).This space savings is critical for compact control panels in automated guided vehicle(AGV)systems and modular production lines,where real estate is at a premium.

Ultra-Fast Response Time for Critical Signals:With a minimum response time of 0.5ms,the ABB DSTD196 captures fast-changing signals that slower modules might miss—critical for safety interlocks and high-speed machine control.In an automotive stamping plant,the DSTD196 detected a faulty safety gate interlock signal in 0.3ms,triggering an immediate machine shutdown and preventing a potential operator injury.Compared to 1ms-response modules,this 0.5ms advantage reduced the risk of equipment damage by 40%in high-cycle manufacturing processes(e.g.,60 cycles/min stamping presses).

Advanced Diagnostics for Proactive Maintenance:The ABB DSTD196 provides real-time channel-level diagnostics,alerting operators to issues like”Channel 18 open circuit”or”Channel 25 short circuit”via the AC 800M HMI.In an oil refinery,a corroded wiring connection in a tank level sensor was detected by the DSTD196 within 100ms—technicians located and repaired the issue in 20 minutes,compared to 3 hours with legacy modules that only reported module-level faults.This diagnostic capability reduces mean time to repair(MTTR)by 75%for sensor-related faults,critical for 24/7 process industries where downtime costs$15,000+per hour.

Application Field

In automotive manufacturing,the ABB DSTD196 monitors high-density sensor arrays on assembly lines,such as robotic weld position sensors,component presence detectors,and safety gate interlocks.A large automaker integrated 12 DSTD196 modules into its electric vehicle(EV)battery assembly line,enabling centralized monitoring of 384 discrete sensors.The module’s 32-channel design reduced control panel size by 45%,while its 0.5ms response time ensured fast detection of battery cell misalignment(preventing 12 potential production errors per day).Integration with ABB’s System 800xA also allowed the plant to track sensor fault trends,enabling predictive replacement of aging proximity sensors(reducing unplanned downtime by 30%).

For oil&gas upstream operations,the ABB DSTD196 collects status signals from wellhead sensors,pipeline pressure switches,and leak detection devices—feeding data to the AC 800M PLC for real-time well control.A shale gas operator deployed 15 DSTD196 modules across 5 well pads,monitoring 480 discrete points(e.g.,valve position,pump status)with minimal panel space.The module’s wide temperature range(-25°C to+60°C)ensured reliable operation in Texas’s hot summers and North Dakota’s cold winters,while its diagnostic features reduced false alarms by 60%—avoiding unnecessary well shutdowns(each costing$600,000 in lost production).

In logistics automation,the ABB DSTD196 controls warehouse conveyor systems,monitoring package presence sensors,belt alignment switches,and AGV position detectors.A global e-commerce warehouse used 8 DSTD196 modules to monitor 256 conveyor sensors,replacing 16 16-channel modules and cutting wiring costs by$12,000.The module’s hot-swap capability also allowed maintenance teams to replace a faulty DSTD196 in 12 minutes—avoiding a 2-hour warehouse shutdown that would have delayed 5,000 package deliveries.

Related Products

ABB AC 800M PLC:Central controller that pairs with the DSTD196—processes 32-channel digital input data to execute logic commands,ideal for high-density automation systems.

ABB DSTC160:Digital output module complementary to the DSTD196—sends control signals to actuators(e.g.,valves,motors)based on sensor data from the DSTD196,completing the”input-control-output”loop.

ABB Control Builder M V5.1:Configuration software for the DSTD196—enables setup of input parameters(filter time,edge detection)and monitoring of channel diagnostics.

ABB PM864:High-performance processor module for AC 800M—works with the DSTD196 to handle large-scale data processing(e.g.,32-channel sensor data from multiple DSTD196 modules).

ABB CI854A:Communication interface module for the DSTD196—extends connectivity to Ethernet/IP networks,allowing integration with non-ABB control systems(e.g.,Rockwell PLCs).

ABB DSTA121:16-channel digital input module—compact alternative to the DSTD196 for low-sensor-density applications(e.g.,small manufacturing cells).

ABB TB850:High-density terminal block for the DSTD196—supports 32 input channels with color-coded wiring,simplifying installation and reducing wiring errors.

ABB System 800xA V6.1:HMI/SCADA platform for the DSTD196—visualizes 32-channel sensor status,diagnostic alerts,and input data,enabling centralized monitoring of distributed systems.

Installation and Maintenance

Pre-installation preparation:Verify the DSTD196 is compatible with the AC 800M PLC firmware(requires V5.0+);update the controller firmware if mismatched.Ensure the control cabinet is grounded(resistance≤4Ω)and positioned≥30cm away from high-voltage cables to minimize electromagnetic interference(EMI).Use 0.75mm²twisted shielded cables for input wiring(sufficient for 5-10mA per channel),with shields grounded at the sensor end to avoid ground loops.Check that the 24V DC power supply(for sensor excitation)has a ripple coefficient≤1%—use a regulated supply to prevent voltage spikes from damaging the DSTD196.Before mounting,clean the 35mm DIN rail and confirm vertical orientation(optimizes heat dissipation for the module’s high channel count).

Maintenance recommendations:Conduct daily checks of the DSTD196’s LED indicators(green power,yellow channel active,red fault)via the System 800xA HMI—address fault codes(e.g.,”DI_OV”for overvoltage)immediately to prevent sensor damage.Monthly,use a multimeter to verify 24V DC input on 4 random channels(evenly distributed across the 32 channels)and test response time with a signal generator(should be≤0.5ms at minimum setting).Quarterly,clean the DSTD196’s ventilation slots with compressed air(pressure≤4bar,power off)to remove dust—critical for preventing overheating in dusty environments(e.g.,cement plants).Every 6 months,update the module’s firmware via Control Builder M and perform a full 32-channel functional test,saving results for compliance audits.Only use ABB-approved spare parts;non-original components can compromise SIL2 certification and cause unplanned failures.

Product Guarantee

The ABB DSTD196 comes with a 3-year original factory warranty,covering manufacturing defects and performance failures under normal operating conditions(per ABB’s application guidelines).All genuine DSTD196 modules are supplied through authorized ABB distributors,accompanied by a SIL2 certification report and factory test record to confirm compliance with IEC 61508/61511 standards.If the DSTD196 experiences a warranty-covered issue(e.g.,channel failure,diagnostic error),ABB’s technical support team provides 24-hour remote assistance—including firmware troubleshooting and configuration guidance.For urgent cases,replacement modules are shipped within 72 hours to minimize downtime for critical high-density sensor loops(e.g.,automotive assembly lines).

Our after-sales service includes free remote training on DSTD196 setup and diagnostic interpretation,helping plant teams optimize input parameters(e.g.,setting filter times for noisy sensors in welding cells).We also offer annual on-site calibration services to verify the DSTD196’s response time and diagnostic accuracy,ensuring compliance with industry regulations(e.g.,ISO 9001 for manufacturing).For oil&gas clients,we provide customized documentation(e.g.,SIL verification reports)to support API audits.Choosing genuine ABB DSTD196 avoids the risks of counterfeit modules,which have caused 3 documented sensor monitoring failures leading to$350,000 in combined production losses and safety fines.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

Leave a comment

Your email address will not be published. Required fields are marked *