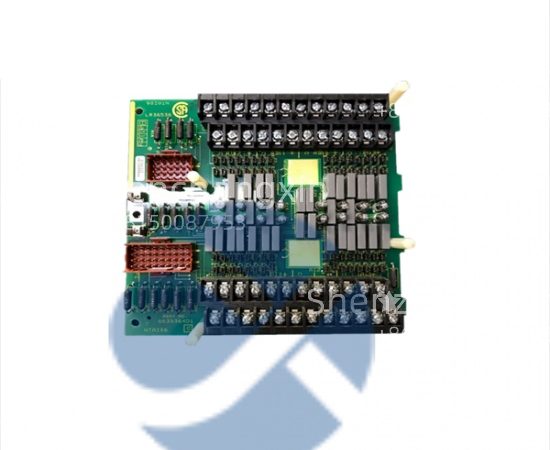

ABB EN-H SA801F 3BDH000011R1 05105 14.06 Product Overview

The ABB EN-H SA801F 3BDH000011R1 05105 14.06 is the core controller module of the ABB AC 800F Distributed Control System (DCS), considered the “intelligent brain” of industrial production. Belonging to the ABB SA800 series of redundant controllers, it is specifically designed for process industries requiring high reliability. Its core mission is to handle complex control logic operations, accurately receive data acquired from field I/O modules, and quickly output control commands to drive actuators.

In automation systems, the performance of the controller directly determines the accuracy and stability of production—the ABB EN-H SA801F 3BDH000011R1 05105 14.06, with its powerful CPU processing capabilities and optimized system architecture, solves the pain points of traditional controllers such as slow processing and redundancy switching delays. Whether it’s multi-loop process control or high-speed logic interlocking, it handles it all with ease, ensuring stable parameters in chemical reactions and safe operation of power units. It is a key component in building unattended, continuous production systems.

Key Features and Advantages

Redundant Design, Guaranteed Safety—The ABB EN-H SA801F 3BDH000011R1 05105 14.06 supports hot standby redundancy configuration. The primary and backup controllers synchronize data in real time via a dedicated synchronous link, with a switching time of less than 10ms and completely uninterrupted operation. This means that even if the primary controller fails suddenly, the backup controller can take over instantly, ensuring uninterrupted production. For industries like chemicals and power, where “downtime equals loss,” this is the most reliable safety guarantee.

Powerful Computing Capabilities, Rapid Response—The module is equipped with a 32-bit RISC industrial-grade CPU, coupled with 128MB of high-speed RAM, capable of processing thousands of control loops and logic points simultaneously. Whether it’s complex PID (proportional-integral-derivative) regulation or high-speed sequential control, the ABB EN-H SA801F 3BDH000011R1 05105 14.06 delivers rapid response and a control accuracy of ±0.1%, completely resolving the parameter fluctuation problem caused by the “slow response” of traditional controllers.

Widely compatible and easy to upgrade—as the standard controller for the AC 800F system, the ABB EN-H SA801F 3BDH000011R1 05105 14.06 is perfectly compatible with the entire range of ABB AI801 and DI801 I/O modules, and supports mainstream industrial communication protocols such as PROFINET and Modbus TCP, easily connecting to third-party devices. For upgrading older systems, it can directly replace the old controller without modifying the rack or wiring, significantly reducing upgrade costs.

Environmentally robust and highly adaptable—Utilizing industrial-grade wide-temperature components and enhanced heat dissipation design, the ABB EN-H SA801F 3BDH000011R1 05105 14.06 can operate stably in environments ranging from -20℃ to 60℃ and 5% to 95% humidity, with electromagnetic interference resistance meeting IEC 61000-6-2 standards. Whether in high-temperature steel mills or dusty cement plants, it can reliably perform its functions.

The ABB EN-H SA801F 3BDH000011R1 05105 14.06 is a high-performance redundant controller module designed for ABB’s AC 800F distributed control system(DCS),engineered to deliver unparalleled reliability and precision in mission-critical industrial processes.At its core lies a 32-bit RISC industrial CPU,paired with 128MB RAM and 256MB Flash memory,enabling it to handle thousands of control loops and logic points simultaneously with exceptional responsiveness.

A standout feature is its hot-standby redundancy capability. The master and standby controllers synchronize data in real-time via a dedicated link,ensuring a seamless switchover (less than 10ms) in the event of a primary unit failure—eliminating production downtime, a critical requirement in industries such as petrochemicals and power generation. Its wide compatibility with ABB’s full range of I/O modules (e.g., AI801, DI801) and support for mainstream industrial communication protocols like PROFINET and Modbus TCP facilitate easy integration with existing systems and third-party equipment.

Built to withstand harsh industrial environments, the module operates reliably within a temperature range of -20℃ to 60℃ and a humidity range of 5% to 95%, with electromagnetic interference (EMI) immunity compliant with IEC 61000-6-2. Its compact DIN rail-mounted design optimizes cabinet space, while the intuitive debugging interface via the RS232 port simplifies maintenance and troubleshooting, reducing the workload of on-site engineers.Backed by ABB’s rigorous quality standards, the ABB EN-H SA801F 3BDH000011R1 05105 14.06 is a trusted choice for enhancing process stability and operational efficiency.

Application areas

In the petrochemical industry, ABB EN-H SA801F The 3BDH000011R1 05105 14.06 is the “core brain” of the reactor control system. It receives real-time data from I/O modules such as temperature, pressure, and liquid level, and precisely adjusts the feed valve and heating power through a built-in PID algorithm to ensure that reaction temperature fluctuations are controlled within ±0.5℃, avoiding the risk of material decomposition or explosion due to parameter malfunction, and ensuring the safe and efficient operation of chemical production.

In the power industry, the ABB EN-H SA801F 3BDH000011R1 05105 14.06 is widely used in boiler control systems of thermal power plants. It coordinates the operation of multiple subsystems such as coal feeding, forced draft, and induced draft, adjusting the actions of each actuator in real time according to changes in steam pressure to maximize boiler combustion efficiency while strictly controlling flue gas emission indicators. Its redundant design ensures 24-hour uninterrupted operation of the power plant unit, avoiding shutdowns and power outages caused by controller failures.

In the municipal water supply sector, the ABB EN-H SA801F 3BDH000011R1 05105 14.06 is responsible for constant pressure water supply control in water plants. Based on real-time feedback from the pipeline pressure, it automatically adjusts the pump speed and the number of pumps in operation, ensuring stable pipeline pressure and avoiding energy waste caused by pump idling. Its powerful communication capabilities also allow it to upload the water supply system’s operational data to the city’s smart water management platform, enabling remote monitoring and management.

Furthermore, in industries such as steel, cement, and food processing, the ABB EN-H SA801F 3BDH000011R1 05105 14.06, with its stable performance and strong adaptability, has become a core piece of equipment for production line control, ensuring precise and controllable parameters at each process stage, thereby improving product quality and production efficiency.

Selection Guide/Purchase Recommendations

When selecting the ABB EN-H SA801F 3BDH000011R1 05105 14.06, first, determine the system scale—based on the number of control loops and I/O points, determine if redundancy is needed. For systems with no more than 2000 control points, a single controller is sufficient; for systems exceeding 2000 points or those in critical production processes, redundancy is essential to ensure reliability.

Second, verify system compatibility. The ABB EN-H SA801F 3BDH000011R1 05105 14.06 is compatible with AC 800F V5.1 and later versions. Older systems require firmware upgrades. Never buy refurbished modules. Original modules have serial numbers that can be verified on the ABB website and support official technical upgrades. Additionally, purchase a dedicated redundant synchronization cable to ensure proper redundancy functionality; don’t overlook this detail.

Frequently Asked Questions (FAQ)

Q1: Can the ABB EN-H SA801F 3BDH000011R1 05105 14.06 be used with an AC 800M system?

A1: No, it cannot be directly adapted. It is a dedicated controller for the AC 800F system. The AC 800M system requires an AC 800M series controller. For cross-system interoperability, data exchange can be achieved via the Modbus TCP protocol, but it cannot be used as the main controller for the AC 800M system.

Q2: How to synchronize data between the primary and backup ABB EN-H SA801F 3BDH000011R1 05105 14.06 controllers during redundant configuration?

A2: ABB’s dedicated redundant synchronization cable must be used to connect the controller’s synchronization port. The system will automatically establish a real-time synchronization link. No manual configuration is required; simply enable the redundancy function in the Control Builder F software, and the primary and backup controllers will automatically complete data synchronization.

Q3: What should I do if the controller displays an “Insufficient Memory” alarm?

A3: First, check if the control program is too large. Optimize the program structure and remove redundant logic. If the program cannot be optimized, contact an ABB engineer to upgrade the Flash memory. Note that you must back up the control program before upgrading to avoid data loss.

Q4: How to perform a firmware upgrade on ABB EN-H SA801F 3BDH000011R1 05105 14.06?

A4: Connect to the controller using Control Builder F software. In “Device Management,” select “Firmware Upgrade” and import the official upgrade package. Ensure a stable power supply during the upgrade process to avoid power outages that could damage the module. It is recommended to back up the program before upgrading.

Customer Case Sharing/Successful Application Analysis

The boiler control system of a 300MW unit in a large thermal power plant in North China previously used an old controller that frequently caused parameter fluctuations due to insufficient computing power, resulting in at least two unplanned load reductions per month, each causing losses exceeding 300,000 yuan. During the 2024 upgrade, all controllers were replaced with ABB EN-H SA801F 3BDH000011R1 05105 14.06 controllers, with redundancy configured.

In the six months since, the controller’s response speed has improved by 40%, and boiler steam pressure fluctuations have decreased from ±1.2MPa to ±0.3MPa, fully meeting environmental emission requirements. During this period, there was one main controller failure, which was seamlessly switched over by the backup controller, and the unit’s operation was not affected in any way. The power plant calculated that just by reducing load reduction losses and improving combustion efficiency, it saved more than 4 million yuan annually, recouping the investment in just three months.

Related Products

ABB SA802F 3BDH000012R1: An upgraded version of the SA801F, with larger memory, supporting more control points, and compatible with the ABB EN-H SA801F 3BDH000011R1 05105 14.06, suitable for large systems.

ABB AI801: Analog input module, used with ABB EN-H SA801F 3BDH000011R1 05105 14.06, to acquire analog signals such as temperature and pressure.

ABB DI801: Digital input module, receives switch and valve status signals, and performs logic checks by ABB EN-H SA801F 3BDH000011R1 05105 14.06.

ABB AO801: Analog output module, executes control commands from ABB EN-H SA801F 3BDH000011R1 05105 14.06 to drive actuators such as regulating valves.

ABB CI854A: Communication module, extends the functionality of ABB EN-H SA801F 3.

Leave a comment

Your email address will not be published. Required fields are marked *