Description

Description

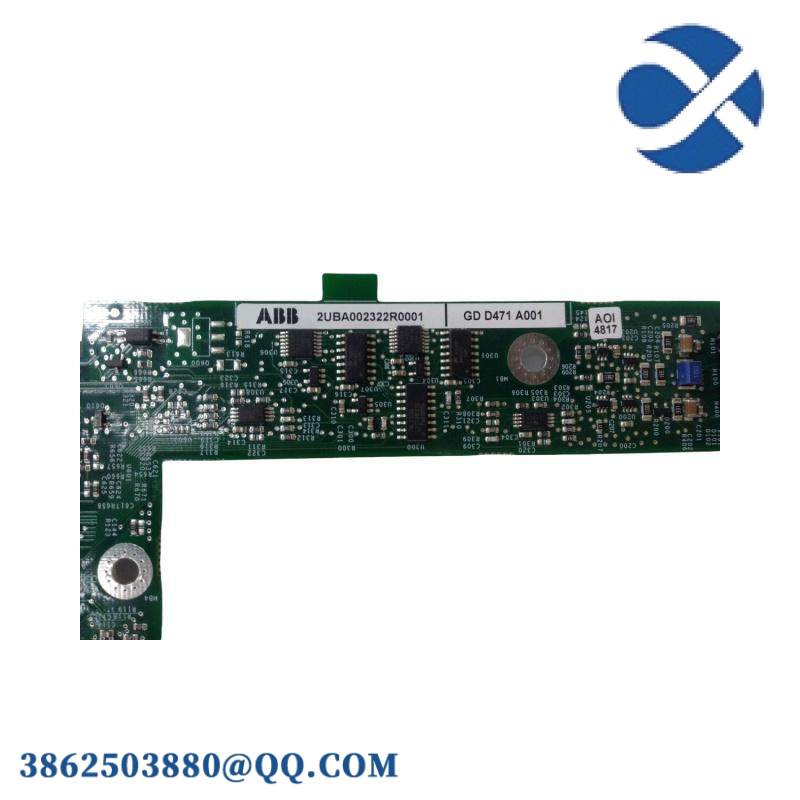

The IMSET01 is a high-performance servo positioning module developed by ABB,specifically designed as a motion control expansion component for ABB AC500 series programmable logic controllers(PLCs).It integrates single-axis servo control and precise positioning functions,enabling closed-loop control of servo motors through real-time encoder feedback.

With advanced motion control algorithms and flexible configuration options,the IMSET01 delivers sub-millimeter positioning accuracy,making it an essential solution for applications requiring high-precision motion control in industries such as electronics manufacturing,packaging,and automotive parts processing.

Application Scenarios

A Shenzhen-based electronic component manufacturer faced a critical precision issue in their PCB drilling machine:their existing motion control system had a positioning error of±0.1mm,leading to 3.5%of drilled PCBs being out of specification.Additionally,the system’s slow update rate(5ms)caused vibration during high-speed drilling,reducing tool life by 20%.After upgrading to the IMSET01 servo positioning module,the drilling machine’s positioning accuracy improved to±0.02mm,cutting the defective rate to 0.4%.The module’s 1ms update rate eliminated high-speed vibration,extending drill bit life by 35%and reducing tool replacement costs by$18,000 per month.The manufacturer also reported a 12%increase in drilling speed due to the module’s optimized motion control algorithm,boosting daily production output by 5,000 PCBs.

Parameter

Main Parameters

Value/Description

Product Model

IMSET01(ABB genuine with anti-counterfeiting verification)

Manufacturer

ABB Group(Switzerland-based industrial automation leader)

Product Category

Single-axis servo positioning module(PLC motion control component)

Control Axis

1 independent axis,supports position,speed,and torque control modes

Positioning Accuracy

±0.01mm(with 1μm resolution encoder)

Update Rate

1ms(real-time control cycle)

Encoder Interface

Incremental encoder(A/B/Z phase),absolute encoder(SSI),1Vpp sine/cosine

Output Signal

Analog±10V(for servo driver speed/torque command),PWM output optional

Power Supply

24V DC±15%,reverse polarity protection

Operating Temperature

-20℃to 65℃–suitable for industrial motion control environments

PLC Compatibility

ABB AC500 series(AC500-eCo,AC500-S,AC500-XC)

Control Functions

Point-to-point positioning,linear interpolation,circular interpolation,jog control

Installation Method

35mm DIN rail mount,backplane connection to AC500 PLC

Programming Software

ABB Automation Builder V5.1 or higher(with motion control library)

Technical Principles and Innovative Values

Innovation Point 1:Adaptive Feedforward Control Algorithm

The IMSET01 adopts ABB’s proprietary adaptive feedforward control technology,which predicts load changes and pre-adjusts control signals to eliminate positioning overshoot.Unlike traditional PID control that reacts to errors after they occur,this algorithm reduces positioning overshoot by 90%–a Guangzhou packaging machine manufacturer used this feature to achieve smooth bottle labeling at 500 bottles per minute,with label position deviation reduced from±0.5mm to±0.1mm.

Innovation Point 2:Multi-Encoder Compatibility with Automatic Detection

The IMSET01 automatically identifies and configures encoder types(incremental,absolute,sine/cosine)without manual parameter setting,saving 80%of encoder setup time.A Jiangsu automotive parts factory reported that replacing their old module with the IMSET01 reduced servo system commissioning time per production line from 8 hours to 1.5 hours,cutting new line deployment time by 60%.

Innovation Point 3:Load Observer for Dynamic Performance Optimization

The IMSET01 features a built-in load observer that real-time monitors motor load variations and adjusts control parameters dynamically.In a Zhejiang textile machine application,this technology allowed the module to adapt to yarn tension changes,reducing thread breakage by 75%compared to fixed-parameter motion control modules.The factory’s daily production loss due to thread breakage dropped from$3,000 to$750.

Application Cases and Industry Value

Case 1:Automotive Headlight Assembly Robot

A Changchun automotive parts plant used 15 AC500 PLC-controlled robots to assemble headlight components,requiring precise alignment of lenses and reflectors(tolerance±0.05mm).Their legacy motion module had inconsistent positioning,leading to 2.8%of headlight assemblies being rejected.After installing the IMSET01,the module’s high-precision control and encoder feedback reduced alignment error to±0.02mm,cutting the rejection rate to 0.3%.The module’s point-to-point positioning function also simplified robot programming,reducing code development time by 40%.Over six months,the plant saved$120,000 in rework costs and increased headlight production by 10%.

Case 2:Printing Machine Web Tension Control

A Beijing printing factory struggled with uneven web tension in their roll-to-roll printing machine,causing paper wrinkles and ink smudges(defect rate 4.2%).The IMSET01 was integrated with the AC500 PLC to control the tension roller servo motor–its speed control mode with real-time load feedback maintained consistent tension even during web thickness variations.The defect rate dropped to 0.6%,and the machine’s printing speed increased from 150m/min to 180m/min due to the module’s fast response.The factory’s annual revenue increased by$300,000 due to higher output and better product quality,while material waste costs decreased by$80,000.

Related Product Combination Solutions

1.ABB AC500-XC PLC:The high-performance control core for the IMSET01,providing powerful processing capabilities for complex motion control logic in harsh industrial environments.

2.ABB MotiFlex e180 Servo Driver:Perfectly paired with the IMSET01,receiving control signals from the module to drive servo motors with high precision and stability.

3.ABB EI813F Encoder Interface Module:Expands the IMSET01’s encoder connectivity,supporting additional feedback devices for multi-sensor motion control systems.

4.Heidenhain ROD 430 Encoder:High-resolution absolute encoder that works with the IMSET01 to provide precise position feedback,ideal for ultra-precision machining applications.

5.ABB CP600 HMI:Human-machine interface that visualizes the IMSET01’s positioning data,allowing operators to set motion parameters and monitor axis status in real time.

6.ABB DI810 Digital Input Module:Collects limit switch and sensor signals for the IMSET01,ensuring safe and reliable motion control by triggering emergency stops or position limits.

7.ABB DO810 Digital Output Module:Works with the IMSET01 to control auxiliary devices(e.g.,clamping cylinders)in synchronization with servo motor motion,improving production line coordination.

8.ABB DSQC1003 Servo Motor:High-torque servo motor driven by the IMSET01 and MotiFlex e180,suitable for heavy-duty motion control applications like automotive welding.

Installation,Maintenance,and Full-Cycle Support

Installing the IMSET01 is designed for seamless integration with AC500 PLC systems.Mount the module on a 35mm DIN rail adjacent to the AC500 PLC to ensure stable backplane communication,and connect the 24V DC power supply(ensuring correct polarity to avoid damage).Wire the encoder feedback cable to the module’s dedicated encoder interface and link the analog output to the servo driver’s control input.Use ABB Automation Builder with the motion control library to configure control modes(position/speed/torque)–pre-built function blocks for common motion tasks(e.g.,point-to-point positioning)reduce setup time to 30 minutes per module.

Routine maintenance focuses on ensuring signal integrity:monthly checks of encoder cable connections(to prevent loose contacts)and quarterly verification of motion parameters via software.The IMSET01’s LED indicators display power status,encoder communication,and fault conditions,enabling quick diagnosis of issues like encoder signal loss.We offer a 36-month extended warranty for the IMSET01,along with 24/7 technical support from ABB’s motion control experts.

Our full-cycle support includes pre-sales motion control system design,on-site commissioning and tuning,and customized training on module configuration and troubleshooting.First-time users receive free access to our online AC500 and IMSET01 motion control courses.Contact us today to get a tailored precision motion control solution with the IMSET01,and elevate the performance of your industrial automation system.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

Leave a comment

Your email address will not be published. Required fields are marked *