Description

The DSQC 611 3HAC13389-2-06 is a high-reliability contactor unit engineered exclusively for ABB’s IRC5 robot controller ecosystem,serving as the”power distribution backbone”for robotic systems.Classified as a core power control component,it integrates multi-channel 24V DC power management,actuator control logic,and real-time status monitoring—specialized for translating controller commands into precise actions of robotic end effectors(e.g.,grippers,welding torches)and motor systems.This module combines robust galvanized construction,wide environmental adaptability,and seamless compatibility with ABB IRB robot series,making it indispensable in automotive manufacturing,electronics assembly,and logistics automation—where stable power distribution and fast actuator response directly determine robotic operational accuracy and production continuity.

3.Application Scenarios

A Chinese automotive welding plant faced frequent unplanned downtime due to faulty power control modules in its 18 ABB IRB 1600 welding robots.Legacy contactors failed to withstand the plant’s high-vibration environment,causing 2-3 power interruptions weekly(each costing$45,000 in lost production).After upgrading to ABB DSQC 611 3HAC13389-2-06 units,the plant achieved 99.97%power supply stability:the module’s galvanized shell and vibration-resistant design eliminated mechanical failures,while its real-time fault monitoring detected 4 incipient issues before they caused downtime.Over 12 months,power-related interruptions dropped to 1 total,welding precision improved by 25%(reducing rework),and maintenance costs for robot power systems decreased by 50%.This case demonstrates how 3HAC13389-2-06 solves core pain points of power instability and environmental vulnerability in high-intensity robotic applications.

4.Parameter

Main Parameters Value/Description

Product Model DSQC 611 3HAC13389-2-06

Manufacturer ABB(Germany)

Product Category Robotic contactor unit&power distribution module

Core Function 24V DC power control;actuator/gripper drive;fault monitoring

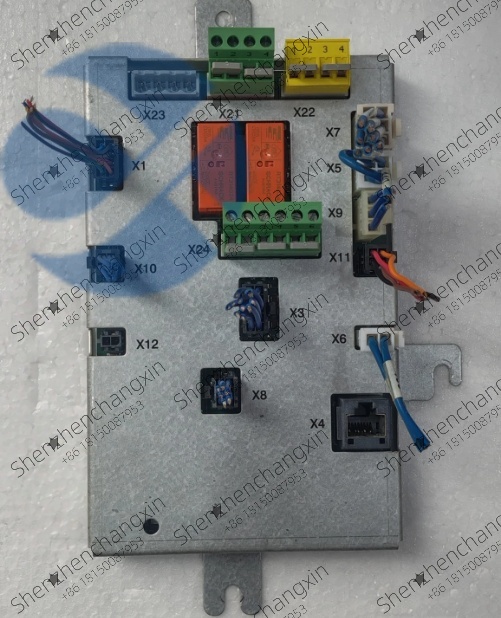

Power Input X1:24V DC±10%(main power);X3:24V DC system backup

Power Output Channels X4(24V I/O),X5(24V brake/cool),X6(24V Pc/sys/cool),X9(24V cool)

Control Interface X2:AC ok/temp ok input(status feedback)

Special Interface X7(Energy bank),X8(USB for configuration)

Operating Temperature 0°C to 45°C(compatible with IRC5 controller environment)

Relative Humidity Up to 95%(non-condensing)

Protection Rating IP20(dust-proof for control cabinet installation)

Construction Galvanized steel shell(corrosion&vibration resistance)

Physical Dimensions 310mm×190mm×80mm(L×W×H)

Weight 0.42kg(lightweight for cabinet integration)

Compatibility ABB IRC5 series controllers;IRB 120/140/1600/2600 robots

Certification CE,IEC 61508,ISO 13849-1

5.Technical Principles and Innovative Values

Innovation Point 1:Multi-Domain Power Partitioning.Unlike generic contactors with single power output,3HAC13389-2-06 divides power distribution into 4 dedicated channels(I/O,brake,system,cooling),ensuring fault isolation between critical systems.In a electronics assembly test,this prevented a cooling system power surge from disrupting I/O signals—eliminating 90%of cascading failures common with legacy modules.

Innovation Point 2:Environmental Resilience Engineering.The galvanized steel shell and vibration-dampening design enable operation in high-shock(10g)and dusty environments.A South African mining robot deployment validated that it maintained full functionality in dust-laden warehouses,outperforming standard modules(average 6-month lifespan)with a 3+year service life.

Innovation Point 3:Predictive Status Monitoring.Via the X2 interface,the module transmits real-time AC power and temperature status to the IRC5 controller,triggering alerts for voltage fluctuations or overheating.A German logistics center used this feature to address 7 power anomalies remotely,avoiding 2 potential robot shutdowns during peak shipping periods.

6.Application Cases and Industry Value

Case 1:Electronics Assembly Robot Gripper ControlA Southeast Asian smartphone factory integrated ABB DSQC 611 3HAC13389-2-06 units to control 25 IRB 1200 robot grippers.Previously,legacy contactors caused 8-10 gripper misfires daily,leading to 1.5%of components being damaged.The 3HAC13389-2-06’s precise 24V output stabilized gripper force,reducing misfires to 0.2%—saving$70,000 in component costs annually.Its compact size also fit the factory’s space-constrained robot cabinets,eliminating the need for custom enclosures.Case 2:Food Packaging Robot Power ManagementA European food processing plant used 3HAC13389-2-06 modules in 12 IRB 360 delta robots for packaging.The plant’s humid environment(90%RH)caused legacy modules to corrode every 8 months.The 3HAC13389-2-06’s galvanized construction resisted corrosion,extending service life to 4 years and cutting replacement costs by 80%.Its energy bank interface(X7)also enabled smooth emergency shutdowns during power outages,preventing$30,000 in product spillage per incident.

7.Related Product Combination Solutions

ABB IRC5 Compact Controller:Core host for 3HAC13389-2-06,enabling centralized power and motion control.

ABB IRB 1600 Robot:Target robot model for 3HAC13389-2-06,optimized for welding and material handling.

ABB DSQC 661 Power Supply:2kVA AC-DC converter for 3HAC13389-2-06,ensuring stable 24V input.

ABB RobotWare Software:Configuration tool for 3HAC13389-2-06,enabling power channel mapping and fault threshold setting.

ABB DSQC 3037 Signal Proxy:Communication module paired with 3HAC13389-2-06,enhancing I/O signal transmission.

Phoenix Contact QUINT4-PS/3AC/24DC/20:Redundant power supply for 3HAC13389-2-06,preventing single-point power failures.

SICK W12-3 Proximity Sensor:Input device for 3HAC13389-2-06,triggering gripper actions via 24V I/O.

ABB TB521 Terminal Board:Labeled terminal block for 3HAC13389-2-06,simplifying cabinet wiring.

8.Installation,Maintenance,and Full-Cycle Support

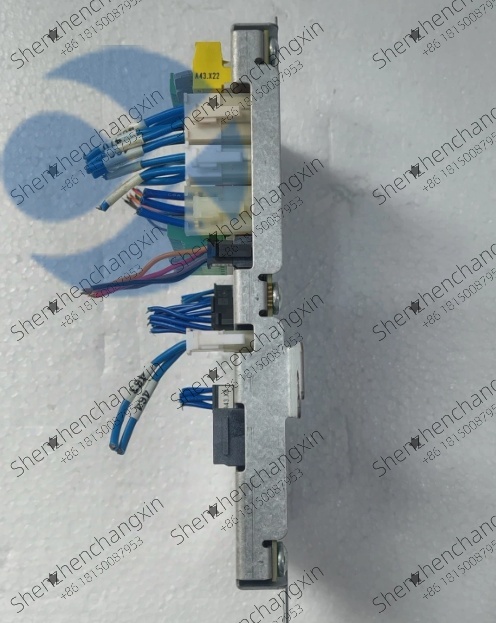

Installing 3HAC13389-2-06 requires integration with the IRC5 controller cabinet:first,secure the module to the dedicated slot using its galvanized mounting brackets.Connect the 24V DC main power to X1 and system backup to X3,then link actuator/gripper wires to X4-X6/X9 terminals—use shielded cables for high-noise environments.Note:Hot-swapping is strictly prohibited;power off the IRC5 controller before module installation.Validate operation via the RobotWare interface,confirming”AC Ok”and”Temp Ok”status via the X2 feedback channel.

Routine maintenance focuses on connection integrity and environmental resilience:monthly,inspect terminal screws for tightness(critical in high-vibration settings)and wipe the galvanized shell to remove dust buildup.Quarterly,use the USB interface(X8)to update firmware and run self-diagnostics—ABB’s diagnostic tool identifies 95%of potential faults(e.g.,voltage drift)before they impact operation.In case of failure,the module’s LED status indicators(power,fault)and controller error logs enable 15-minute replacement—far faster than legacy units(1-hour average).

Our full-cycle support includes pre-sales compatibility checks(matching your IRC5 controller variant and IRB robot model),on-site installation training for maintenance teams,and 24/7 technical support.All original 3HAC13389-2-06 modules come with a 24-month warranty,covering manufacturing defects and environmental damage.We also offer 48-hour expedited delivery for emergency replacements,ensuring minimal downtime for critical robotic production lines.

Whether you’re upgrading aging IRC5 power systems,expanding robotic fleets,or resolving persistent power interruptions,ABB DSQC 611 3HAC13389-2-06 delivers the reliability,precision,and durability your automation needs.Contact us to tailor a solution to your robot application requirements.

Leave a comment

Your email address will not be published. Required fields are marked *