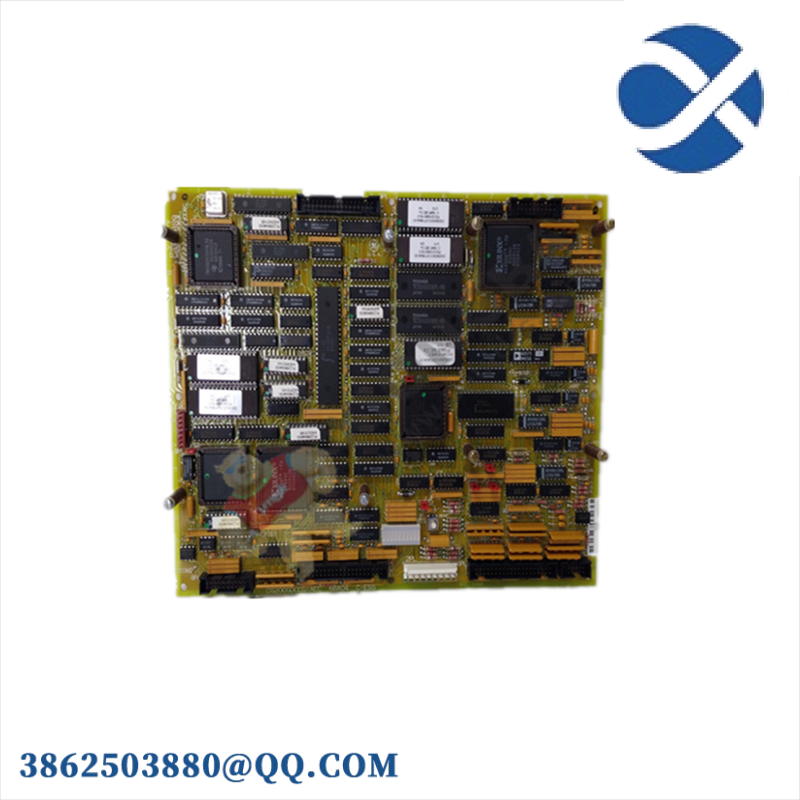

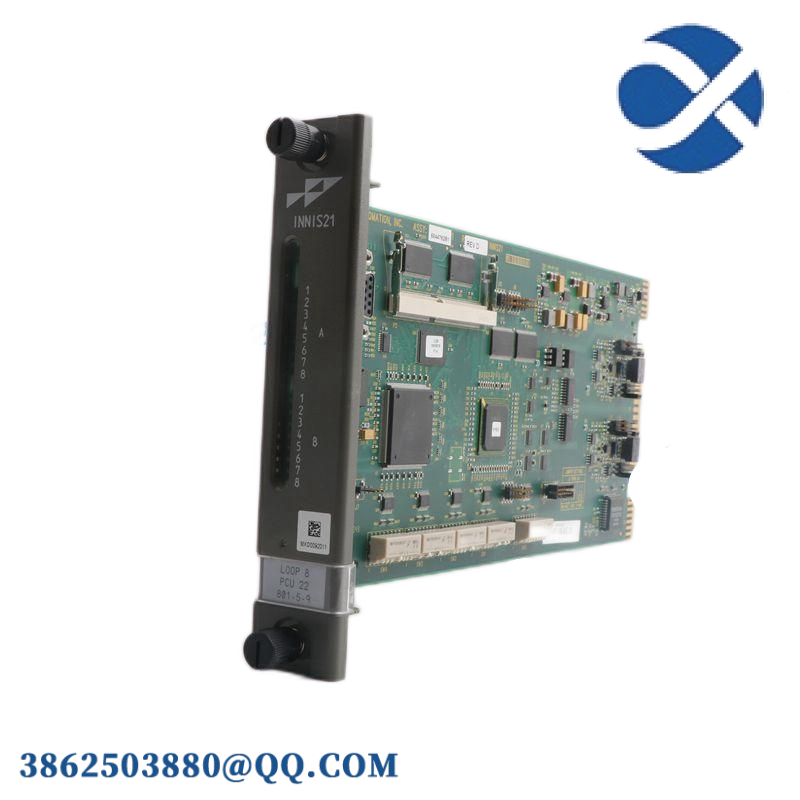

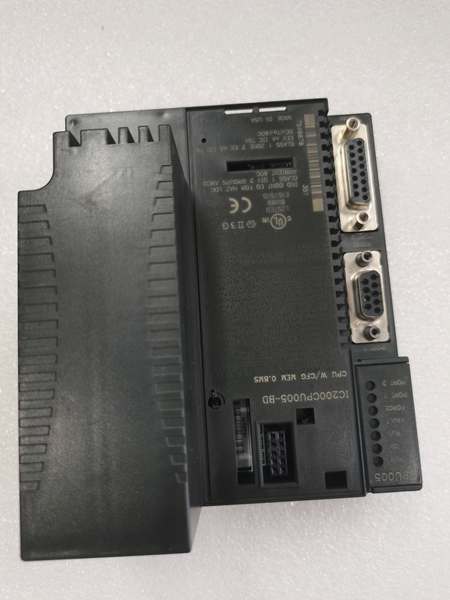

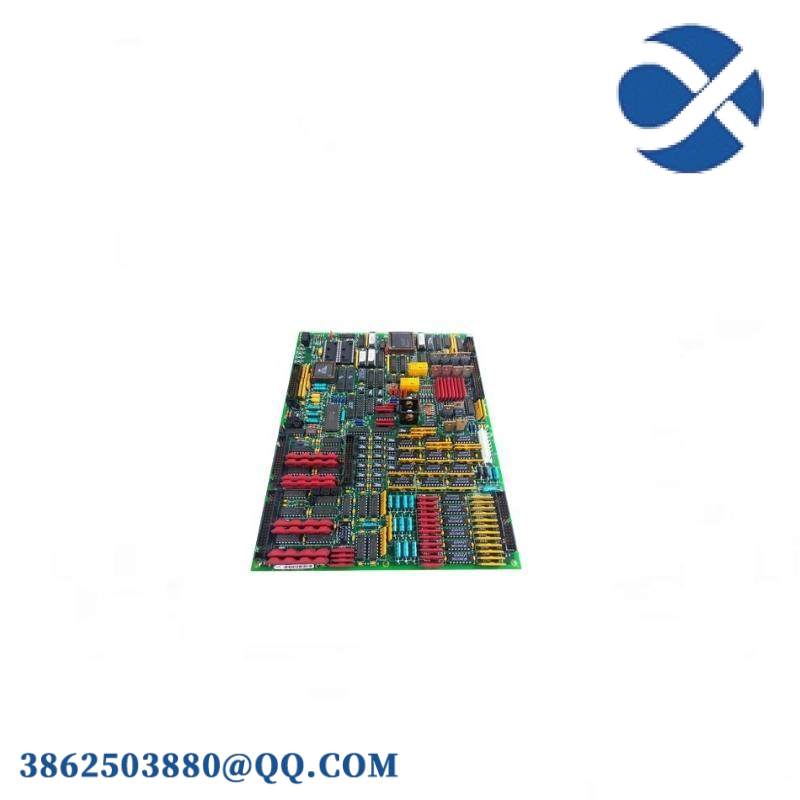

GE IC697MDL740

Product Description

The GE IC697MDL740 is a discrete output module designed for the GE Fanuc Series 90-70 PLC systems. It is used to power devices such as motor starters, solenoids, and indicators. The module provides 16 output points grouped into four isolated clusters of four points each, with each point capable of handling 24/48V DC at a rate of 2 amperes.

Product Parameters

-

Rated Voltage: 24 or 48 volts DC.

-

Number of Outputs: 16 (four groups of four outputs each).

-

Output Current: 2 Amps per point, 4 Amps per group.

-

Current Required: 0.15 Amps.

-

Output Voltage Range: 20 to 60 volts.

-

DC Power: Yes.

Product Specifications

-

Isolation: 1500 volts between any output and the backplane, 500 volts between groups.

-

Inrush Current: 20 amps maximum for 20 ms.

-

Output Voltage Drop: 0.8 volt (0.4 ohm) maximum.

-

Response Time:

-

On: 2 ms maximum.

-

Off: 2 ms maximum.

-

-

Output Leakage: 1 mA maximum.

Series

The GE IC697MDL740 belongs to the GE Fanuc Series 90-70, which is known for its robustness and versatility in industrial automation.

Features

-

High Inrush Capacity: Suitable for a wide range of inductive and incandescent loads.

-

LED Indicators: Provide the ON/OFF status of each point and fuse status.

-

Mechanical Keying: Ensures correct replacement with a similar type in the field.

-

User-Configurable I/O References: Without the need for DIP switches or jumpers.

Functions

-

Powering Devices: Motor starters, solenoids, and indicators.

-

System Integration: Integrates seamlessly with GE Fanuc PLC systems.

-

Real-Time Monitoring: Provides real-time status updates through LED indicators.

Uses

The GE IC697MDL740 is used in various industrial applications, including:

-

Manufacturing: For process control and automation.

-

Energy Management: For controlling and monitoring power generation equipment.

-

Process Control: For managing industrial processes in chemical and petrochemical plants.

Application Fields

-

Manufacturing: Automotive, electronics, food & beverage.

-

Energy: Power generation, oil and gas.

-

Process Control: Chemical and petrochemical plants