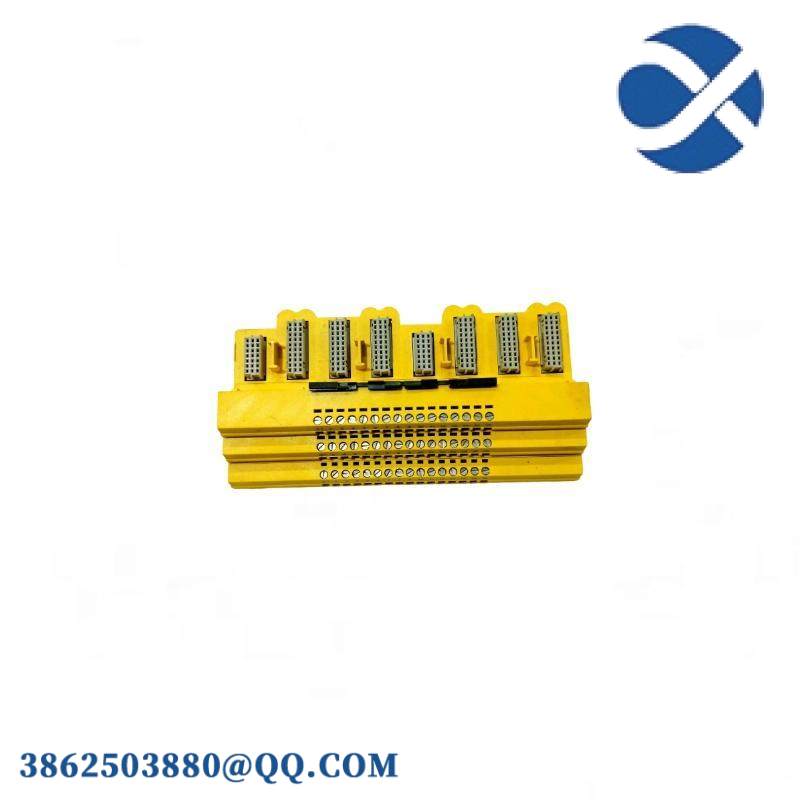

Emerson A3120/022-000 CSI3120

🏷️ Product Overview: Emerson A3120/022-000 (CSI3120)

The Emerson A3120/022-000 (also known as CSI3120) is a machine protection and vibration monitoring system designed for use in industrial environments to monitor the health of rotating machinery such as turbines, compressors, pumps, and motors.

It is part of the CSI 3100/6100 Machinery Protection System , used for both predictive maintenance and real-time machine protection . The system provides continuous monitoring of key parameters like vibration, speed, phase, and temperature.

📋 Product Description

The CSI3120 is a modular vibration monitoring card that serves as the core processor within the CSI 3100 or 6100 rack-based protection system . It receives signals from proximity probes, velocity sensors, and tachometers, processes the data, and generates alarms or shutdown signals if abnormal conditions are detected.

This module ensures safe operation of critical rotating equipment by detecting early signs of mechanical issues such as:

- Imbalance

- Misalignment

- Bearing wear

- Shaft eccentricity

- Rotor rub

It communicates with control systems such as PLCs, DCSs, or SCADA systems , providing real-time diagnostics and alarm outputs.

🔧 Product Parameters & Specifications

⚙️ Features & Functions

- Real-Time Vibration Monitoring : Continuously tracks vibration levels on rotating machines.

- Alarm and Trip Outputs : Provides alert and danger level relay outputs for machine protection.

- Signal Processing : Analyzes vibration spectra for fault detection (e.g., imbalance, misalignment).

- Diagnostics Support : Enables predictive maintenance through trend analysis and spectral data.

- Multiple Input Channels : Supports multiple sensor inputs (e.g., shaft displacement, casing vibration).

- Integration Ready : Interfaces with PLCs, DCSs, HMIs, and SCADA systems via standard protocols.

- Rugged Industrial Design : Built for reliability in harsh environments.

- User Configuration : Configurable via software tools like System 1™ or local HMI.

🛠️ Typical Uses & Applications

- Turbine Protection : Steam, gas, and hydro turbines

- Compressor Monitoring : Centrifugal, axial, and reciprocating compressors

- Pump Surveillance : Critical pumps in refineries, chemical plants, and power stations

- Generator and Motor Protection

- Condition-Based Maintenance (CBM) Programs

- Oil & Gas Production Platforms

- Power Generation Plants (Fossil, Nuclear, Renewable)

- Marine and Offshore Machinery Monitoring

📦 Related Series & Products

- CSI 3100 / CSI 6100 Series : Complete machinery protection racks

- CSI Sensors : Proximity probes (e.g., 3300 XL), accelerometers, tachometers

- System 1™ Software : Asset management and diagnostics platform

- Bently Nevada 3500 Monitoring System

- SCADA and Predictive Maintenance Integration Tools

Emerson A3120/022-000 CSI3120