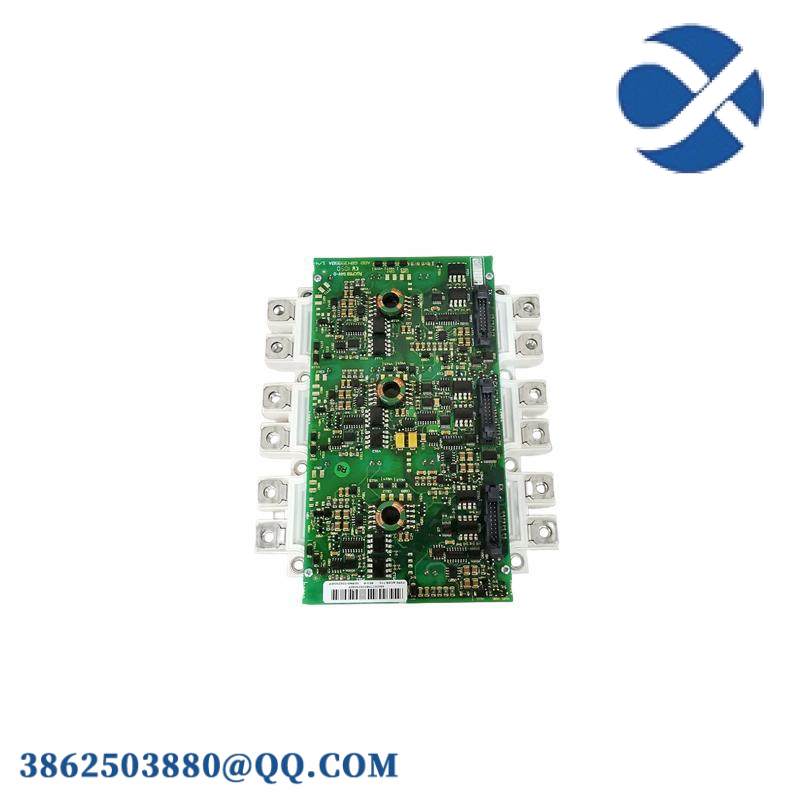

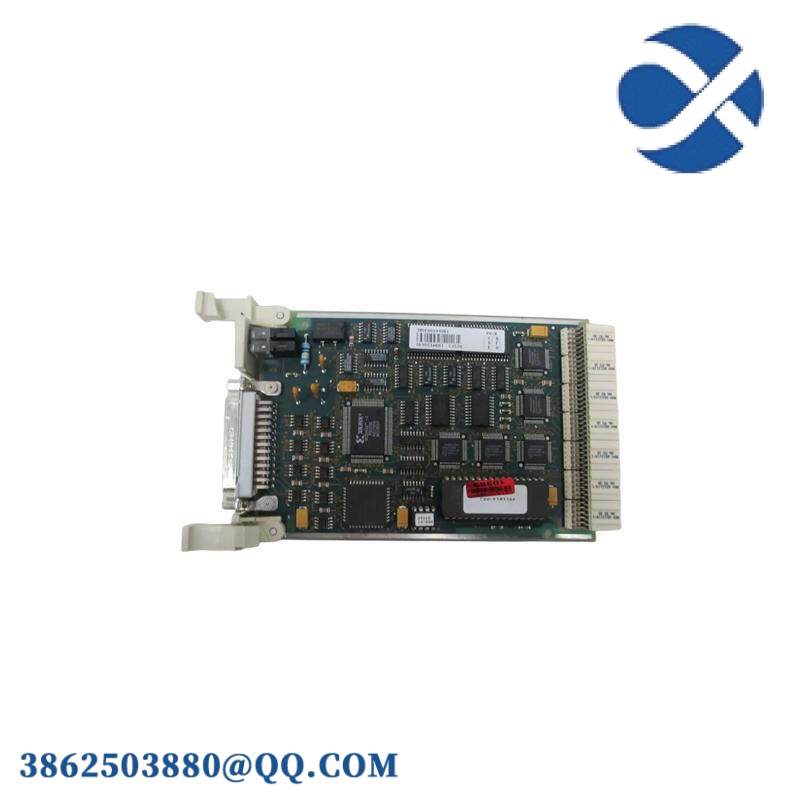

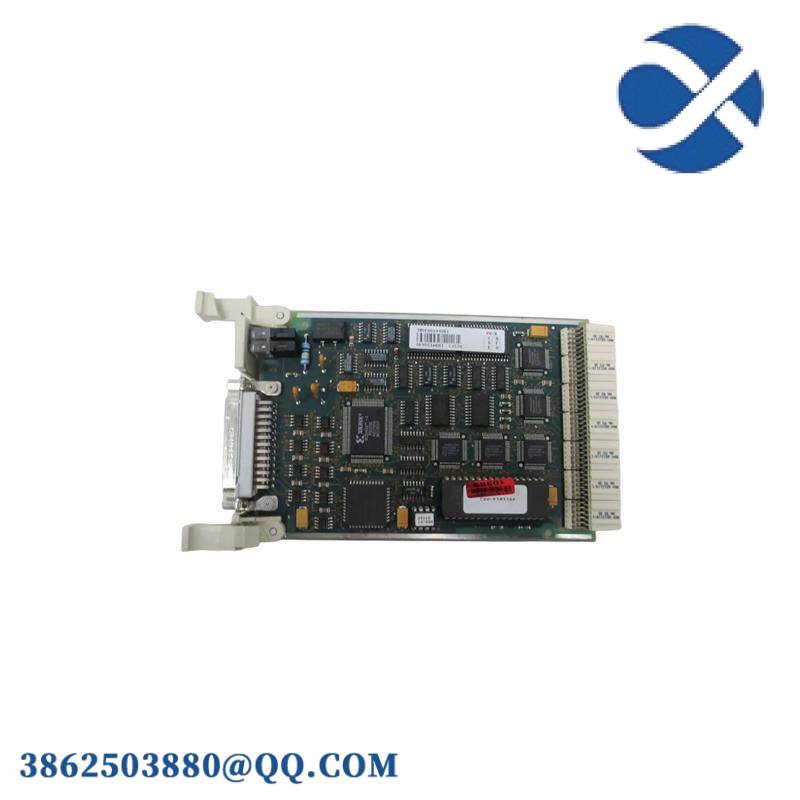

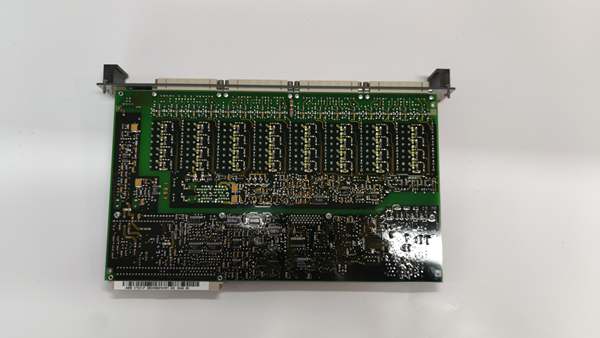

BENTLY 3500/53 133388-01大卡

Product Description

The BENTLY 3500/53 133388-01 is an electronic overspeed detection module designed for the Bently Nevada 3500 Series machinery protection system. It provides reliable and fast-response overspeed protection for rotating machinery, ensuring compliance with industry standards such as API 670 and API 612. The module accepts transducer signals from proximity probes or magnetic pickups, monitors rotational speed, and triggers alarms or shutdowns when overspeed conditions are detected.

Product Parameters

- Model: 3500/53 133388-01

- Brand: Bently Nevada

- Series: 3500 Series Machinery Protection System

- Input Signal:

- Accepts a single transducer signal from proximity probe or magnetic pickup.

- Input signal range: +10.0 V to -24.0 V (internally limited).

- Input impedance: 20 kΩ.

- Transducer Compatibility:

- Bently Nevada 3300 8 mm Proximitor®, 3300 16 mm HTPS, 7200 5 mm, 8 mm, 11 mm, and 14 mm Proximitor®, 3300 RAM Proximitor®, or magnetic pickups.

- Power Consumption: 8.0 Watts (typical).

- Outputs:

- Front panel LEDs indicate module status (OK, TX/RX, Bypass, Test Mode, Alarm).

- Buffered transducer output: Coaxial connector with short-circuit and ESD protection, 550 Ω output impedance, -24 Vdc, 40 mA maximum.

- Relay outputs: Single-pole, double-throw (SPDT) relays with epoxy sealing, 250 Vrms (AC), 30 Vdc (DC) max switched voltage, 5 A max switched current.

- Frequency Response:

- Supports 1 to 255 events per revolution.

- Maximum full-scale range: 99,999 rpm.

- Maximum input frequency: 20 kHz.

- Environmental Specifications:

- Operating temperature: -20°C to +65°C.

- Storage temperature: -40°C to +85°C.

- Humidity: 95% non-condensing.

Product Specifications

- Redundancy:

- Can be combined to form a 2-out-of-2 or 2-out-of-3 voting system for enhanced reliability.

- Requires redundant power supplies in the 3500 rack.

- Display & Configuration:

- Configurable via 3500 Rack Configuration Software.

- Front panel LEDs provide real-time status feedback.

- Mechanical:

- Designed for 19-inch EIA rack mounting.

- Dimensions: 24.3 cm (H) x 4.6 cm (W) x 15.5 cm (D) (module only).

- Weight: 1.12 kg (module only).

Series

- Bently Nevada 3500 Series: A modular, scalable machinery protection system used for continuous monitoring and protection of rotating equipment in harsh industrial environments.

Features

- High Reliability: Designed to meet API 670 and API 612 standards for overspeed protection.

- Redundant Configuration: Supports 2-out-of-2 or 2-out-of-3 voting systems for critical applications.

- Wide Speed Range: Monitors rotational speeds up to 99,999 rpm with high accuracy.

- Real-Time Alarming: Provides immediate visual and relay-based alarms for overspeed conditions.

- Easy Integration: Seamlessly integrates with the 3500 system and other industrial automation components.

- Robust Design: Withstands harsh industrial environments with wide temperature and humidity tolerances.

Function

- Overspeed Detection: Continuously monitors rotational speed and triggers alarms or shutdowns when overspeed conditions are detected.

- Status Indication: Provides real-time feedback on module status via front panel LEDs.

- Data Transmission: Outputs buffered transducer signals and relay contacts for integration with control systems.

- Configuration: Customizable via 3500 Rack Configuration Software for specific application requirements.

Purpose

- Ensures the safe operation of rotating machinery by preventing overspeed-related failures.

- Reduces downtime and maintenance costs through early fault detection and protection.

- Complies with industry standards for overspeed protection in critical applications.

Applications

- Power Generation: Turbines, generators, and compressors in power plants.

- Oil & Gas: Drilling platforms, compressors, and pumps.

- Petrochemicals: Rotating machinery in chemical processing plants.

- Metallurgy & Mining: Large rotating equipment in mining operations.

- Marine Engineering: Propulsion systems and auxiliary machinery on ships.

- Industrial Automation: Integration with PLC, DCS, and SCADA systems for centralized monitoring and control.

- Aerospace: Critical rotating components in aircraft engines and auxiliary systems.

BENTLY 3500/53 133388-01大卡

BENTLY 3500/53 133388-01大卡