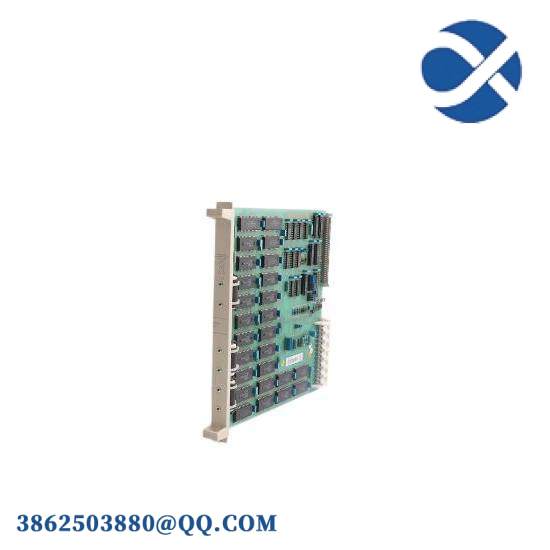

Product Description

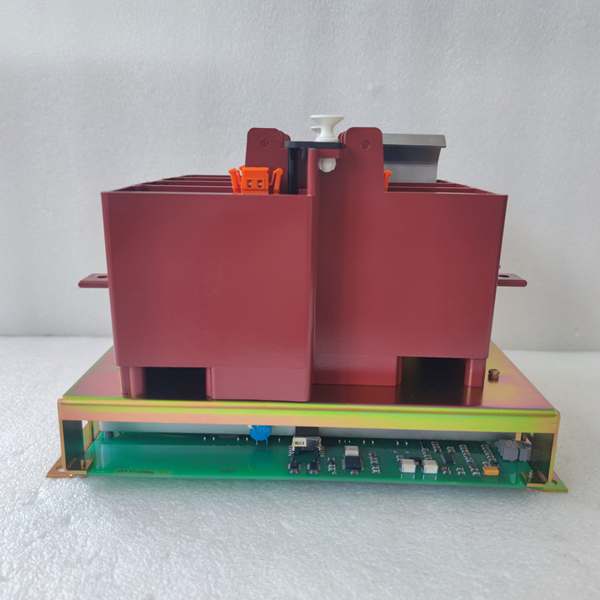

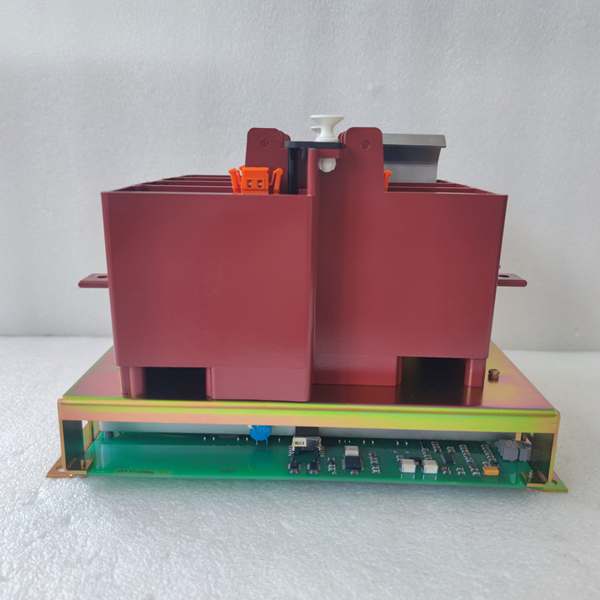

The ABB 500SCM01 1MRE450004R1 is a high-performance CPU module designed for the ABB System 500 series programmable logic controllers (PLCs). It serves as the core control unit of the AC500-eCo/AC500-S series and is positioned as the central controller for medium to large industrial automation systems. This module is designed to support redundant architecture, multi-protocol communication, and high-precision motion control, making it suitable for applications in rail transportation, energy generation, metallurgical steel rolling, water treatment, and other scenarios where reliability, real-time performance, and scalability are critical.

Product Parameters

-

Model: 500SCM01

-

Order Number: 1MRE450004R1

-

CPU Architecture: ARM Cortex-A9 dual-core processor, 1GHz main frequency, single-core processing performance of 1.2 DMIPS/MHz.

-

Memory Configuration:

-

Program Memory: 512MB (expandable to 2GB) to support complex logic and algorithms.

-

Data Memory: 256MB (with battery backup), data retention time after power failure >10 years.

-

Extended Storage: Supports microSD card (up to 32GB) for log/recipe storage.

-

Control Performance:

-

Scan Cycle: Typical value 0.1-10ms (configurable), suitable for high-speed motion control (e.g., flying shears, winding).

-

Logic Operation Capability: Supports more than 100,000 instructions/second, meeting the needs of large programs (e.g., plant-wide energy management systems).

-

Redundancy and High Availability:

-

CPU Redundancy: Supports 1:1 hot standby, main and standby CPUs synchronized through optical fiber, switching time <50ms (compliant with IEC 61508 SIL 2).

-

Communication Redundancy: Dual Ethernet ports support STP/RSTP/MSTP protocols for network link redundancy.

-

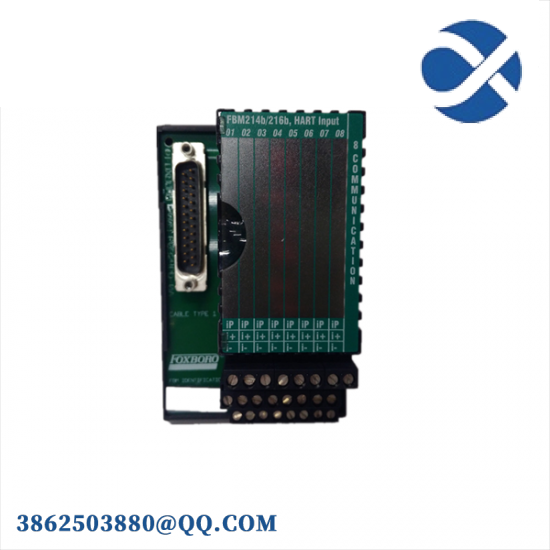

Communication and Network Integration:

-

EtherCAT Master: Supports 1000 slave nodes, communication cycle <1ms, suitable for multi-axis synchronous motion control (e.g., printing machines, robots).

-

PROFINET/EtherNet/IP: Integrated dual Gigabit Ethernet ports, supports OPC UA server, seamlessly connects to MES/SCADA systems.

-

Modbus TCP/RTU: Compatible with traditional devices, supports 256 TCP connections and 512 RTU slaves.

-

Industrial Internet of Things (IIoT): Built-in MQTT client protocol stack, can directly connect to cloud platforms (e.g., AWS/Azure) for remote monitoring and predictive maintenance.

-

Data Encryption: Supports TLS 1.3/AES-256 encryption to ensure the security of industrial data transmission.

-

Motion Control and Expansion:

-

Axis Support: Single CPU module can control 32-axis synchronous motion (through EtherCAT expansion), supporting electronic cam, flying shear, chasing shear, and other processes.

-

Positioning Accuracy: Interpolation cycle 250μs, repeat positioning accuracy ±0.01mm (combined with ABB servo drive).

-

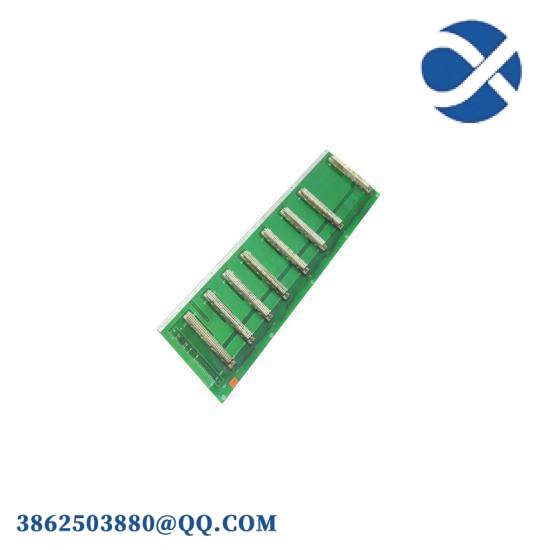

Local Expansion: Supports 32 local I/O modules (e.g., 500DI/DO, 500AI/AO) through CEX bus, with a maximum expansion distance of 10m.

-

Remote Expansion: Connect remote I/O stations (e.g., 500XR distributed modules) through optical fiber/Ethernet to achieve 10km remote control.

-

Safety and Compliance:

-

Functional Safety: Complies with IEC 61508 SIL 3, ISO 13849 PL e, TÜV Rheinland certification, supports safety PLC functions (e.g., emergency stop, safety door monitoring).

-

Safety Communication: Integrated FSoE (Functional Safety over EtherCAT) protocol for safe I/O and drive communication.

-

Environmental Adaptability: Operating temperature -25°C to +60°C (fanless cooling), IP20 protection level (rack-mounted), vibration and shock resistance in accordance with IEC 60068-2 standard.

Series

The ABB 500SCM01 1MRE450004R1 belongs to the ABB System 500 series, which is part of the AC500-eCo/AC500-S series designed for industrial automation and control systems.

Features

-

High-Performance Computing and Control: Equipped with a powerful ARM Cortex-A9 dual-core processor and ample memory to handle complex control tasks.

-

Redundancy and High Availability: Ensures system reliability through CPU and communication redundancy, with quick failover capabilities.

-

Advanced Communication Capabilities: Supports multiple industrial protocols and provides robust network integration options.

-

Motion Control: Capable of controlling multiple axes with high precision, suitable for applications requiring synchronized motion.

-

Safety and Compliance: Meets stringent safety standards and is designed for harsh industrial environments.

Functions

-

Core Control: Acts as the central controller for medium to large industrial automation systems.

-

Data Processing and Communication: Handles data processing and facilitates communication between different devices and systems.

-

Real-Time Monitoring and Control: Provides real-time monitoring and control capabilities for industrial processes.

-

Safety and Protection: Ensures system safety through compliance with international safety standards.

Uses

-

Industrial Automation: Used in manufacturing lines, robotics, and material handling.

-

Process Control: Monitors and controls processes in power systems, substations, and distribution networks.

-

Energy Management: Manages energy consumption in power plants and substations.

-

Transportation: Used in railway automation and marine control systems