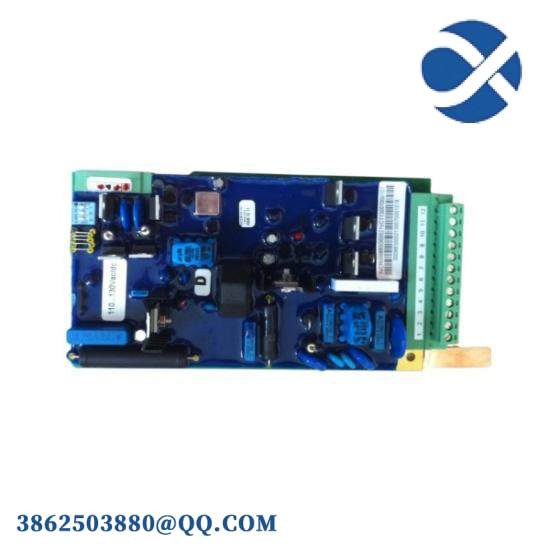

ABB SYN5200a-Z,V217 SYNCHROTACT5 3BHB006713R0217

Product Description

The ABB SYN5200a-Z, V217 SYNCHROTACT5 3BHB006713R0217 is a high-performance digital synchronizer designed for automatic synchronization and paralleling of generators with power lines and synchronous lines. It is part of the fifth generation of ABB’s SYNCHROTACT series, known for its advanced dual-channel design and high reliability.

Product Parameters

-

Operating Frequency: Up to 1000 Hz

-

Regulation Accuracy: ±0.25%

-

Protection Rating: IP65

-

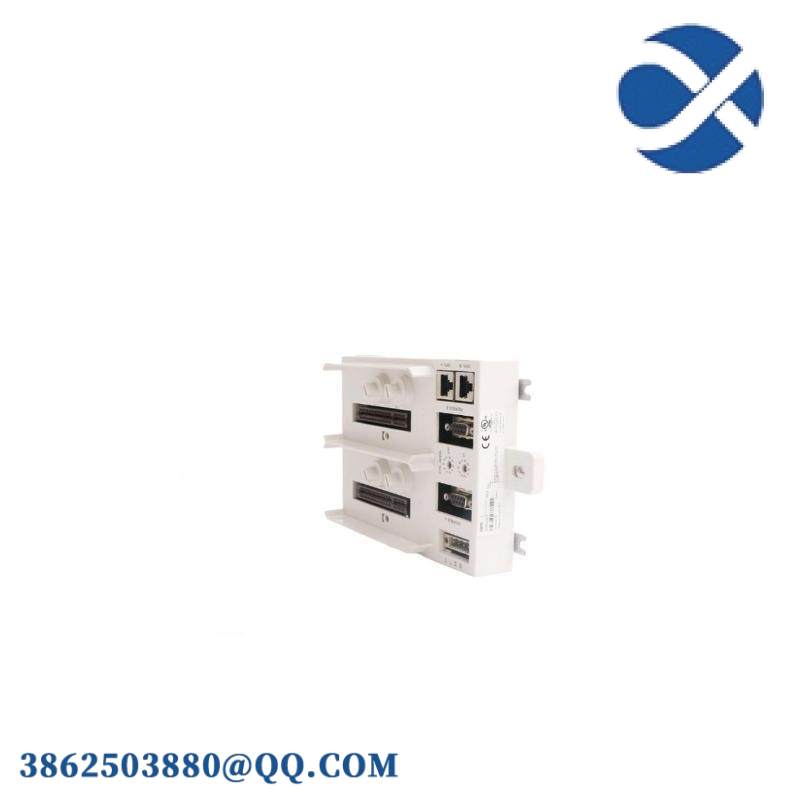

Communication Interfaces: Ethernet, USB, RS485

-

Control Modes: Manual, automatic, and remote control

-

Communication Protocols: Modbus, Profibus DP, PROFINET

Product Specifications

-

Dimensions: 178 x 114 x 44 mm

-

Weight: 1.2 kg

-

Installation Method: 19-inch rack mount

-

Operating Temperature Range: -25°C to +60°C

-

Storage Temperature Range: -40°C to +85°C

Series

The SYN5200a-Z belongs to the SYNCHROTACT 5 series, which is part of ABB’s synchronization equipment line.

Features

-

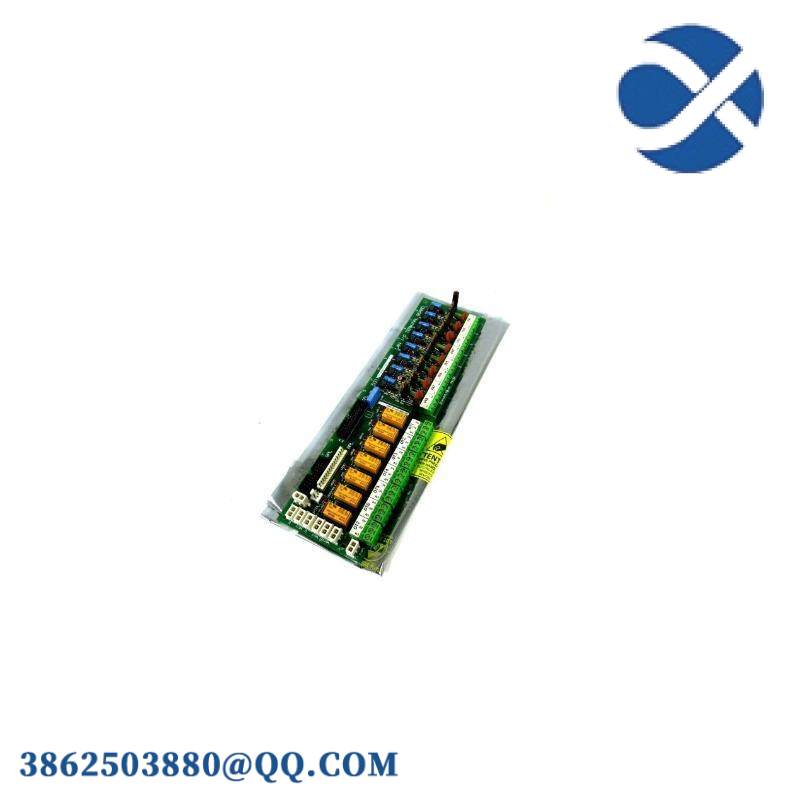

Dual Channel Design: Enhances safety and availability.

-

Automatic Synchronization: Supports automatic synchronization of generators and power lines using the IEC 61850 communication protocol.

-

Remote Servicing: Capable of remote servicing via TCP/IP and Internet.

-

Remote Control: Supports remote control via fieldbus (Modbus, Profibus, LON).

-

Dead Bus / Dead Line Feature: Ensures safe operation in various conditions.

-

Compliance: Designed in compliance with IEC protection standards and CE certification guidelines.

Functions

-

Generator Synchronization: Automatically adjusts the frequency and phase of generators to synchronize them with the grid.

-

System Protection: Provides protection functions to prevent damage to generators and power systems.

-

Data Acquisition and Processing: Real-time monitoring and control of equipment.

Uses

-

Power Generation: Ensures stable power output in small hydropower and thermal power plants.

-

Marine Applications: Ensures stable operation of ship generators.

-

Industrial Automation: Provides stable excitation for synchronous motors in mining, factories, and other scenarios.

Application Fields

The SYN5200a-Z is widely used in:

-

Power Systems: For voltage stabilization in power plants and substations.

-

Marine Power Systems: For stable power supply in marine electric propulsion and auxiliary systems.

-

Industrial Automation: Ensuring stable operation of industrial machines and synchronous motors.

-

Renewable Energy: Enhancing the efficiency of wind and solar power systems