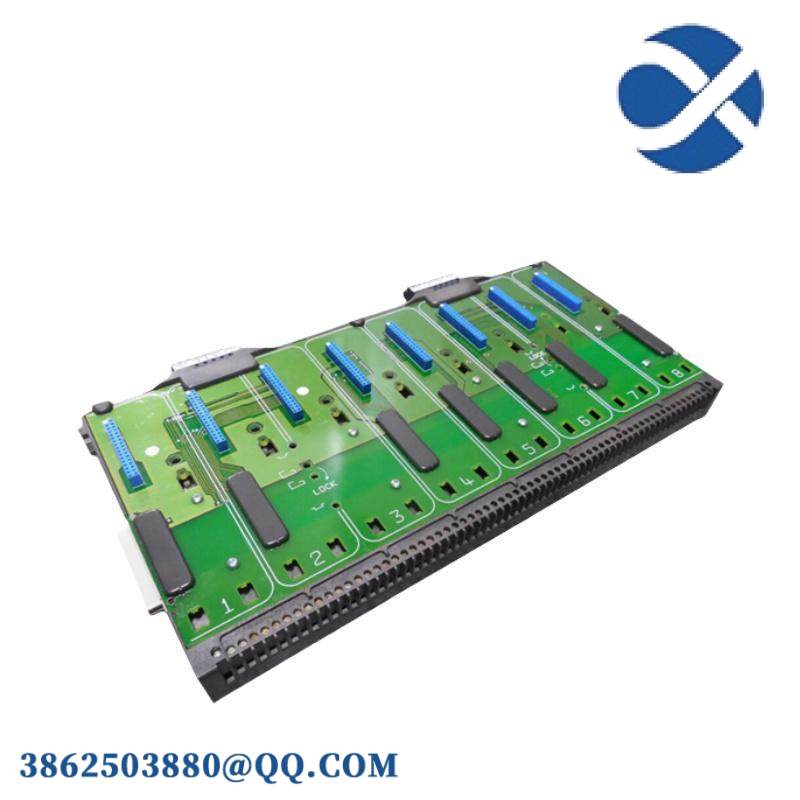

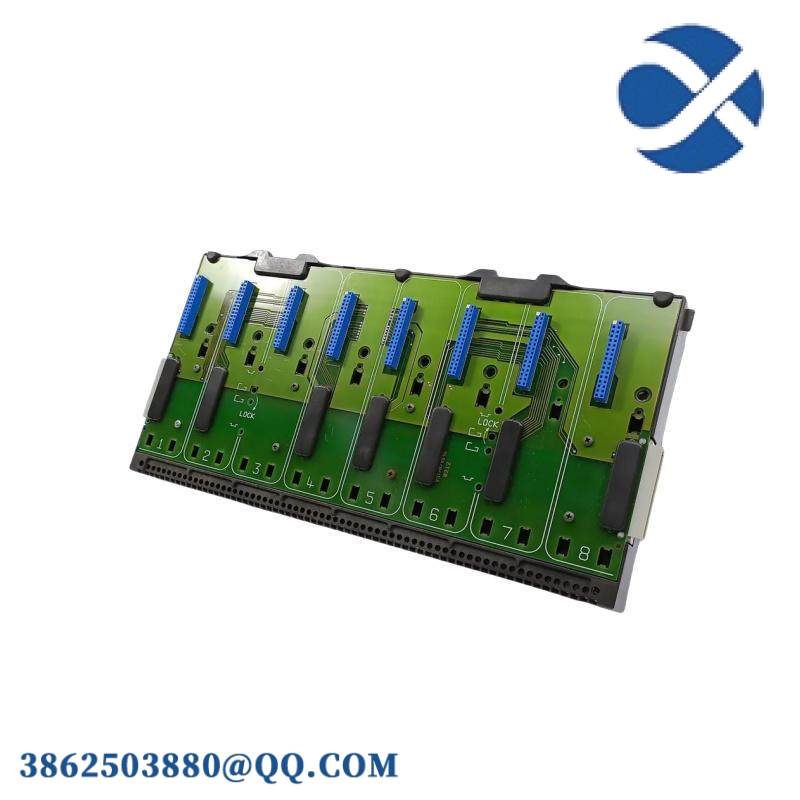

EMERSON 5X00500G01

Product Description

The Emerson 5X00500G01 is a high-reliability 32-channel digital output module designed for Emerson’s Ovation™ distributed control system (DCS). It enables precise control of discrete field devices in industrial automation environments. Engineered to meet the demands of harsh industrial settings, the 5X00500G01 converts digital signals from controllers into 24 VDC outputs to drive relays, solenoids, and actuators, ensuring seamless integration into critical processes across power generation, oil & gas, and manufacturing.

Product Specifications

-

Output Type: 24 VDC current-sourcing (sink/source selectable via jumper)

-

Number of Channels: 32 isolated channels

-

Output Current: 500 mA per channel (2 A total system limit)

-

Isolation: ±1,000 VDC (field-to-logic, channel-to-channel)

-

Response Time: ≤10 ms (programmable 1–100 ms output delay)

-

Input Voltage: 24 VDC ±10% (module power)

-

Power Consumption: ≤15 W (at full load)

-

Operating Temperature: -40°C to 70°C

-

Humidity Resistance: 0–95% RH (non-condensing)

-

Enclosure Rating: NEMA 4X (IP66) for outdoor use

-

Dimensions: 144 mm × 60 mm × 30 mm (W × H × D)

-

Weight: 0.4 kg

-

Compatibility: Emerson Ovation™ DCS, MODBUS RTU

Series

Ovation™ DCS.

Features

-

High-Density Output Capability: Supports 32 output channels in a compact form factor, reducing panel space by 40% compared to legacy 16-channel modules.

-

Enhanced Electrical Isolation: ±1,000 VDC isolation safeguards against ground loops and transient surges, protecting connected equipment.

-

Extreme Environment Resilience: Operates reliably from -40°C to 70°C, making it suitable for arctic oil rigs, desert refineries, and high-temperature industrial furnaces.

-

Proactive Fault Management: Built-in diagnostics and LED status indicators enable quick identification of channel faults, reducing troubleshooting time by 50% in typical scenarios.

Applications

-

Power Generation: Controls circuit breakers, turbine bypass valves, and generator cooling systems in thermal and nuclear power plants.

-

Oil & Gas: Drives solenoids for emergency shutdown (ESD) systems, pump starters in pipeline networks, and valve actuators in refineries.

-

Manufacturing: Manages conveyor belts, robotic arm actuators, and safety interlocks in automotive and food processing facilities.

Application Fields

-

Power Plants: Ensures precise control in power generation systems.

-

Oil and Gas Facilities: Provides reliable operation in harsh environments.

-

Manufacturing Facilities: Enhances efficiency and reliability in production processes.

EMERSON 5X00500G01

EMERSON 5X00500G01