Technical Principles and Innovative Values:

Innovation Point 1:Microprocessor-Driven Precision.Unlike mechanical synchronisers,the DEIF Full Auto Synchronising Relay uses digital algorithms to sample parameters 100x/second,reducing phase angle mismatch to±10°—a 70%improvement over manual methods.This precision cuts inrush current by 90%,extending generator lifespan by 3-5 years.A power plant test found that the relay reduced genset maintenance costs by$40,000 annually compared to legacy systems.

Innovation Point 2:Automatic Parameter Alignment.The relay actively adjusts generator speed(via frequency control)and voltage(via AVR signals)to meet busbar conditions,eliminating the need for manual potentiometer tweaks.In marine trials,this feature reduced paralleling time from 2-3 minutes to 15-30 seconds,critical for emergency power transfer during blackouts.

Innovation Point 3:Rugged,Moving-Part-Free Design.With no mechanical components,the relay avoids wear-related failures common in traditional synchronisers.It maintains accuracy even in high-vibration environments(e.g.,ship engine rooms)and has a mean time between failures(MTBF)of 100,000+hours—5x longer than mechanical alternatives.

Application Cases and Industry Value:

Case 1:Industrial Power Plant Load Management

A 50MW diesel power plant in Southeast Asia relied on manual synchronisation to add gensets during peak demand,leading to 2-3 monthly load drops when parameters misaligned.Installing DEIF Full Auto Synchronising Relay units enabled automatic paralleling of 4 gensets,cutting synchronisation time to 20 seconds and eliminating load disruptions.The plant’s operations manager reported,“The relay lets us respond to demand spikes instantly—we’ve increased revenue by 12%by avoiding peak-hour outages,and generator repairs are down 80%.”

Case 2:Data Center Backup Power

A Tier 3 data center used 3 backup gensets for grid failure protection but struggled with slow manual synchronisation,leaving a 2-3 second power gap that risked server shutdowns.The DEIF Full Auto Synchronising Relay reduced the gap to<100ms by pre-aligning gensets with the grid during standby.During a recent grid outage,the relay completed paralleling in 80ms,protecting 500+servers from data loss.The data center’s IT director said,“The relay turned our backup system from‘reactive’to‘instant’—we haven’t lost a single server since installation.”

Related Product Combination Solutions:

DEIF PPU 300:Paralleling&Protection Unit–Integrates with the Full Auto Synchronising Relay to add engine/generator protection and PLC logic for multi-genset systems.

DEIF LSU-112 DG:Load Sharing Unit–Works with the relay to distribute power evenly across paralleled gensets,preventing overloading.

DEIF CSQ-3:Multi-Function Synchroscope–Provides visual confirmation of synchronisation status alongside the relay’s automatic control.

DEIF DVC 550:Digital AVR–Partners with the relay to adjust generator voltage,ensuring precise voltage matching before paralleling.

DEIF HAS-111 DG:Circuit Breaker Controller–Receives closing signals from the Full Auto Synchronising Relay and adds time compensation for reliable breaker operation.

DEIF RMT-111 Q96:Phase Sequence Meter–Pre-verifies wiring correctness to prevent phase reversal,a critical pre-condition for the relay’s operation.

DEIF EPN-110 DN:Electronic Potentiometer–Adjusts generator speed based on the relay’s frequency signals,enhancing alignment accuracy.

Installation,Maintenance,and Full-Cycle Support:

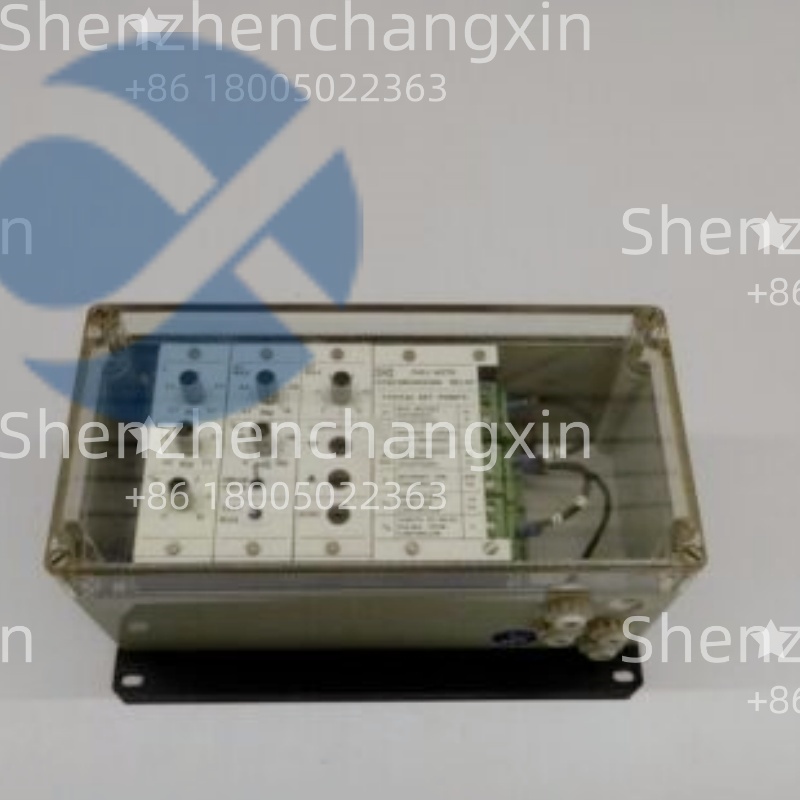

Installing the DEIF Full Auto Synchronising Relay is designed for efficiency:it mounts to 35mm DIN rails or base plates in control cabinets,with clearly labeled terminals for voltage/frequency inputs and relay outputs.Wiring requires connecting generator and busbar voltage sensors,plus a signal wire to the generator breaker—no specialized tools needed.Configuration is done via DIP switches or DEIF’s software,with pre-set parameters for common genset sizes(100-2000kVA)enabling basic operation in 30 minutes.

Routine maintenance is minimal.Inspect the relay quarterly for dust buildup(wipe with a dry cloth)and verify LED status lights(power,synchronisation ready,fault).Annual calibration(via DEIF service tools)ensures parameter accuracy,but the relay’s digital design eliminates drift common in analog systems.If a fault occurs(e.g.,red LED),the relay triggers an alarm and locks out breaker closing—troubleshooting typically involves checking sensor wiring or power supply,with replacement units available for plug-and-play swap.

We provide comprehensive support for the DEIF Full Auto Synchronising Relay,including a 2-year standard warranty(extendable to 3 years for marine/industrial customers).Our technical team includes DEIF-certified specialists available 24/7 for installation guidance,parameter tuning,or emergency support.We maintain global stock in key hubs(Singapore,Houston,Rotterdam)for next-day delivery,minimizing downtime for critical power systems.For fleet operators,we offer free annual system audits to optimize relay settings and ensure compliance with safety standards.

The DEIF Full Auto Synchronising Relay is more than a control device—it’s the backbone of reliable,safe power paralleling.Whether you’re managing shipboard gensets,industrial backup power,or grid-connected plants,it delivers the precision and durability DEIF is trusted for.Contact us today to design a customized synchronisation solution for your power system,and ensure seamless power continuity when it matters most.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

Leave a comment

Your email address will not be published. Required fields are marked *