Description

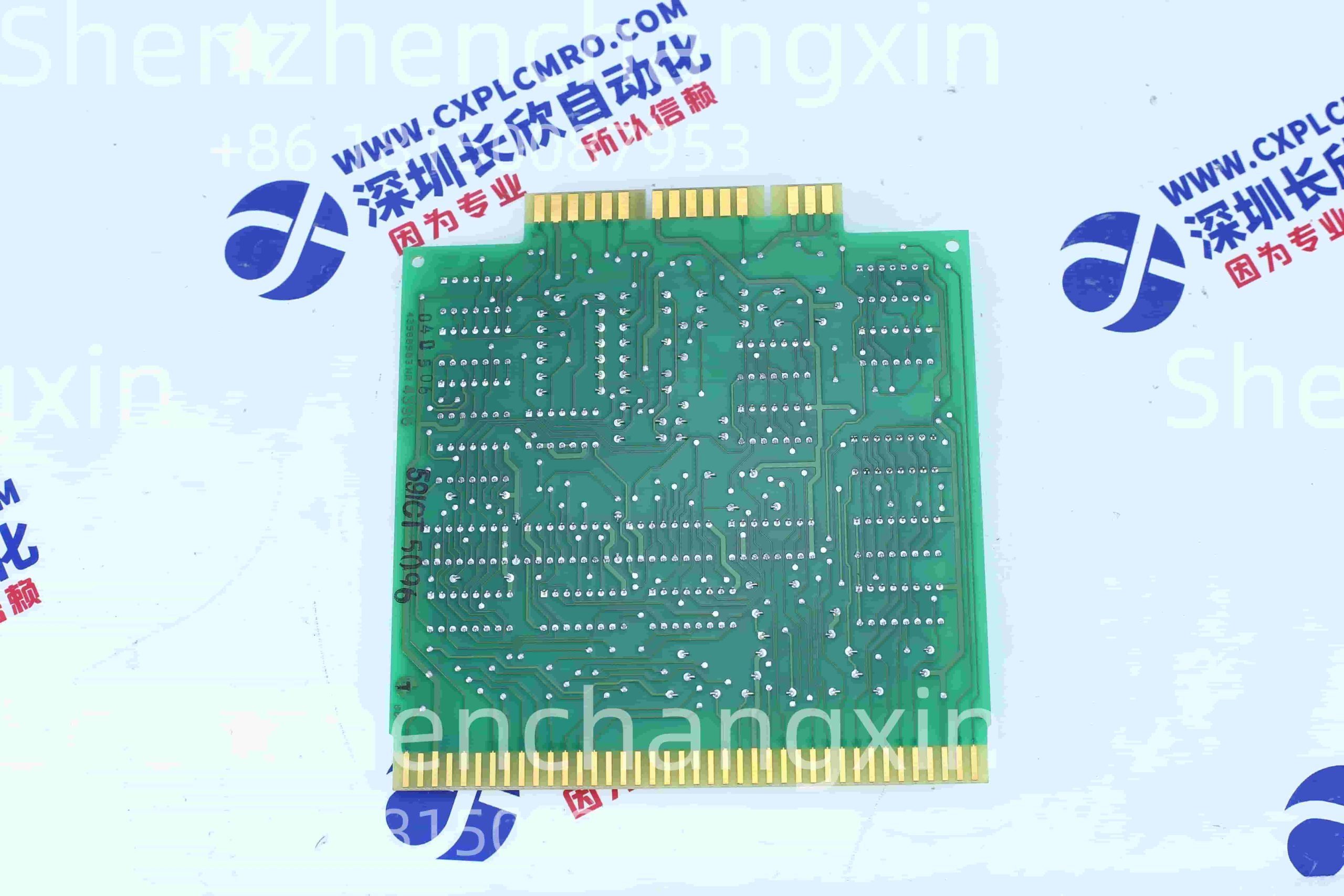

TheDAC 41072001is a high-speed communication controller module designed for the GE Mark VIe Turbine Control System.This module acts as a critical interface within the system’s distributed I/O network,managing data exchange between the central controller and remote I/O packs.It is engineered for high reliability and deterministic performance,essential for the precise control and protection of gas and steam turbines.

Application Scenarios

In a modern power plant,a GE Frame 7HA gas turbine relies on the Mark VIe control system for ultrafast,precise control.Thousands of I/O points from sensors and actuators are distributed across the turbine skid.TheDAC 41072001module is a key component that manages this high-speed I/O network.It ensures that critical data—such as combustor temperatures and valve positions—is communicated to the main controller without delay,and that control commands are sent back with deterministic timing.A failure of this communication module could disrupt the entire I/O network,leading to a loss of control and a forced turbine outage,highlighting its role as a critical nexus for data integrity and system availability.

Parameter

Parameter

Specification

Product Model

DAC 41072001

Manufacturer

GE Energy/GE Vernova

Product Category

I/O Network Communication Controller

Compatible System

GE Mark VIe Turbine Control System

Primary Function

High-Speed I/O Network Management

Communication Protocol

Proprietary GE I/O Network(e.g.,RSTi)

Network Role

Controller/Master for I/O Packs

Data Transfer Rate

High-speed(e.g.,100 Mbps)for deterministic performance

Redundancy Support

Typically used in redundant configurations

Connector Type

High-density,board-to-board connectors

Mounting

Installs into a designated slot within a Mark VIe control rack

Power Supply

Powered via the Mark VIe rack backplane

Status Indicators

LEDs for power,network status,and faults

Technical Principles and Innovative Values

TheDAC 41072001is a cornerstone of the Mark VIe’s distributed I/O architecture,offering significant advancements over previous systems.

Innovation Point 1:Deterministic High-Speed I/O Networking.The primary innovation of theDAC 41072001is its management of a deterministic,high-speed network dedicated to I/O data.This ensures that field data is sampled and control outputs are updated at precise,regular intervals,which is critical for high-speed control loops governing fuel,temperature,and speed in a turbine.This determinism is a key differentiator from standard Ethernet networks.

Innovation Point 2:Distributed Intelligence and Reduced Latency.By acting as a dedicated communication controller,theDAC 41072001offloads the network management burden from the main CPU.This distributed architecture reduces processing latency for I/O data and increases the overall capacity and performance of the control system,allowing it to handle the vast number of points required by modern turbines.

Innovation Point 3:Enhanced Diagnostics and Redundancy.The module provides extensive diagnostics for the entire I/O network it controls.It can detect communication faults with individual I/O packs,cable issues,and network errors.Furthermore,it is designed to work seamlessly in a redundant pair,ensuring continuous operation even if one communication path fails.

Application Cases and Industry Value

Case Study:Ensuring Grid Stability with Fast Response.A combined-cycle power plant used for grid frequency support requires its gas turbine to ramp load up and down within seconds.The control system’s ability to respond this quickly depends on the ultra-reliable,low-latency communication between the controller and the turbine’s actuators.TheDAC 41072001modules in the Mark VIe system were critical to this performance.Their deterministic network ensured that load change commands were executed without jitter or delay.The reliability of these communication controllers was directly linked to the plant’s ability to fulfill its grid support contract and generate ancillary service revenue.

Related Product Combination Solutions

TheDAC 41072001operates within a tightly integrated system of Mark VIe components.

Mark VIe Controller(e.g.,T8431):The central processing unit that relies on theDAC 41072001for I/O data.

I/O Pack Modules(e.g.,IS200-series):The remote I/O terminals that are managed by theDAC 41072001communication controller.

EX2100e Excitation Controller:The excitation system,which integrates with the Mark VIe and uses similar communication modules for its I/O.

Network Switches&Hubs:The network infrastructure components that form the physical I/O network controlled by theDAC 41072001.

IC200-series Modules:Components from the Mark VIe system that interface with the network.

Installation,Maintenance,and Full-Cycle Support

Installation and Maintenance:Installing or replacing aDAC 41072001is a critical task that must be performed by qualified personnel.The turbine must be taken offline and the control system safely isolated.ESD precautions are mandatory.The module is carefully seated into its rack slot.Configuration is handled by the Mark VIe engineering tools,which typically recognize the new hardware and integrate it into the control strategy.Maintenance is primarily predictive and diagnostic,monitoring network health and status indicators.

Our support for theDAC 41072001recognizes its vital role in turbine control networks.We provide fully tested and certified modules to ensure immediate system integration and long-term reliability.Our technical team understands the criticality of these components in maintaining power generation assets.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

Leave a comment

Your email address will not be published. Required fields are marked *