Product Overview

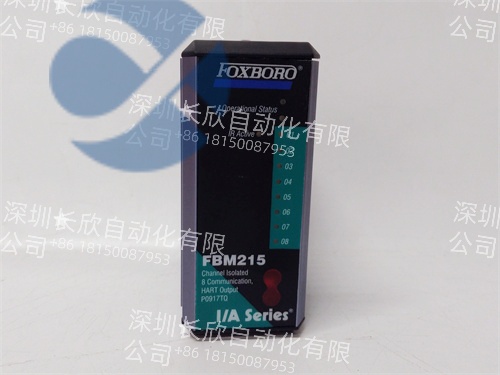

TheFOXBORO FBM215 P0917TQis a high-performance HART communication output interface module manufactured by FOXBORO,a leading provider of industrial automation and control solutions.This advanced fieldbus module serves as a critical component in distributed control systems(DCS),specifically designed to interface with HART-enabled field devices while providing robust channel isolation and communication capabilities.TheFOXBORO FBM215 P0917TQfeatures eight isolated output channels,each capable of supporting standard 4-20mA analog output signals with superimposed HART digital communication,making it an essential component for modern process control applications requiring both analog control and digital device diagnostics.

As part of FOXBORO’s comprehensive automation portfolio,theFBM215 P0917TQintegrates seamlessly with Foxboro Evo™control systems,providing bidirectional digital communication capabilities that enable advanced device configuration,monitoring,and diagnostics.The module’s compact design and rugged construction make it suitable for installation in demanding industrial environments,including G3 grade(severe)environmental conditions as defined by ISA standard S71.04.TheFOXBORO FBM215 P0917TQrepresents a significant advancement in field device integration,offering enhanced diagnostic capabilities and improved system reliability compared to traditional analog-only modules.

The strategic importance of theFOXBORO FBM215 P0917TQlies in its ability to bridge the gap between conventional analog control systems and modern digital field device technologies.By supporting HART protocol communication,the module enables users to leverage the benefits of smart field devices while maintaining compatibility with existing 4-20mA control infrastructure.This dual capability makes theFOXBORO FBM215 P0917TQparticularly valuable in brownfield applications where gradual migration to digital technologies is required,as well as in greenfield installations where future-proofing is a key consideration.

Technical Specifications

Parameter Name

Parameter Value

Product Model

FOXBORO FBM215 P0917TQ

Manufacturer

FOXBORO

Product Type

HART Communication Output Interface Module

Number of Channels

8 isolated output channels

Output Signal

4-20mA analog with HART digital overlay

Communication Protocol

HART(Highway Addressable Remote Transducer)

Isolation

Channel-to-channel and channel-to-ground isolation

Power Supply

24V DC(typical for fieldbus modules)

Operating Temperature

-40°C to+70°C(industrial grade)

Enclosure Rating

ISA S71.04 G3(severe environment)

Communication Rate

HART:1200 bps(standard)

Modulation

FSK(Frequency Shift Keying)

Compatibility

Foxboro Evo™control systems

Dimensions

Compact design(specific dimensions vary)

Weight

Approximately 0.5-1.0 kg

Certification

Industrial standards compliance

Main Features and Advantages

TheFOXBORO FBM215 P0917TQoffers comprehensive HART communication capabilities that significantly enhance field device management and diagnostic functions.Each of the eight output channels supports bidirectional digital communication with HART-enabled field devices,allowing for remote device configuration,calibration,and diagnostic monitoring without interrupting the 4-20mA analog control signal.This dual-signal capability enables users to implement predictive maintenance strategies by monitoring device health parameters such as device status,process variables,and diagnostic information,ultimately reducing downtime and improving overall system reliability.

Advanced isolation technology is a key feature of theFOXBORO FBM215 P0917TQ,providing complete electrical isolation between channels and between channels and ground.This isolation prevents ground loops,reduces electromagnetic interference,and enhances system stability in electrically noisy industrial environments.The module’s robust design includes surge protection and transient voltage suppression,ensuring reliable operation in harsh conditions where electrical noise and voltage spikes are common.The compact form factor of theFOXBORO FBM215 P0917TQallows for high-density installations,maximizing control cabinet space utilization while maintaining excellent thermal performance.

Integration with Foxboro Evo™control systems represents another significant advantage of theFOXBORO FBM215 P0917TQ.The module supports HART universal commands,common practice commands,and device-specific commands,providing comprehensive device management capabilities through the control system interface.This integration simplifies engineering and maintenance tasks by enabling device configuration and diagnostics directly from the operator interface,eliminating the need for separate handheld communicators and reducing the time required for device setup and troubleshooting.

Application Field

TheFOXBORO FBM215 P0917TQfinds extensive application in process industries where precise control and comprehensive device diagnostics are essential.In oil and gas production facilities,the module interfaces with HART-enabled pressure transmitters,temperature transmitters,and level transmitters,providing both control signals and diagnostic information for critical process parameters.The bidirectional communication capability of theFOXBORO FBM215 P0917TQenables remote device configuration and calibration,reducing the need for field personnel to access hazardous areas for routine maintenance tasks.

Chemical processing plants benefit from theFOXBORO FBM215 P0917TQ’s ability to interface with smart valve positioners and analytical instruments.The module’s HART communication capabilities allow for advanced control strategies such as valve characterization and adaptive tuning,improving process control performance and reducing variability.In power generation applications,theFOXBORO FBM215 P0917TQprovides interface capabilities for critical control loops involving flow,pressure,and temperature measurement,while the diagnostic features support condition-based maintenance programs that help prevent unplanned outages.

Water and wastewater treatment facilities utilize theFOXBORO FBM215 P0917TQfor controlling pumps,valves,and chemical dosing systems.The module’s robust design and environmental ratings make it suitable for installation in wet and corrosive environments commonly found in water treatment plants.The HART communication capabilities enable remote monitoring of device health and performance,helping maintenance teams identify potential issues before they impact process operations and ensuring compliance with environmental regulations.

Related Products

FOXBORO FBM214:8-channel analog input module with HART support

FOXBORO FBM216:16-channel digital input module

FOXBORO FBM218:16-channel digital output module

FOXBORO FBM222:8-channel analog input module for thermocouples

FOXBORO FBM223:8-channel analog input module for RTDs

FOXBORO FBM240:Communication module for PROFIBUS DP

FOXBORO FBM241:Communication module for Modbus RTU

FOXBORO FBM242:Communication module for DeviceNet

FOXBORO FBM243:Communication module for Foundation Fieldbus

FOXBORO FBM244:Communication module for Ethernet/IP

Installation and Maintenance

Pre-installation preparation:Proper installation of theFOXBORO FBM215 P0917TQrequires careful planning and adherence to industrial control system standards.Before installation,verify that the control cabinet provides adequate space for proper ventilation and maintenance access,with appropriate clearances around the module.Ensure the mounting surface is properly secured and that the installation environment meets the specified environmental conditions.Check that the power supply meets the module’s requirements(typically 24V DC)and verify proper grounding connections.All field wiring should use appropriate cable types and follow separation guidelines to prevent electrical interference.TheFOXBORO FBM215 P0917TQshould be handled with care to avoid damage to connectors and components,and static discharge precautions should be observed during installation.

Maintenance recommendations:Regular maintenance of theFOXBORO FBM215 P0917TQfocuses on ensuring optimal performance through systematic testing and inspection.Establish a preventive maintenance schedule that includes quarterly visual inspections for signs of damage,contamination,or loose connections.Perform regular function testing of HART communication capabilities to verify proper operation and maintain system integrity.The module’s diagnostic features should be monitored continuously for any fault indications.Keep detailed records of all maintenance activities,function tests,and any operational issues encountered.The modular design of theFOXBORO FBM215 P0917TQfacilitates easy replacement if necessary,minimizing system downtime during maintenance operations while maintaining process control functionality.

Product Guarantee

We guarantee that theFOXBORO FBM215 P0917TQmeets all manufacturer specifications and performance requirements for industrial automation applications.Our comprehensive quality assurance process includes rigorous testing and validation procedures to ensure reliable operation in demanding industrial environments.We provide complete technical support covering system configuration,integration guidance,and operational troubleshooting to ensure successful implementation of theFOXBORO FBM215 P0917TQin your control system.Our commitment extends throughout the product lifecycle,with ongoing support for performance optimization and maintenance planning.We maintain adequate inventory of critical components to support urgent requirements and offer replacement services for defective units within warranty terms,ensuring continuous operation of your industrial processes.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

Leave a comment

Your email address will not be published. Required fields are marked *