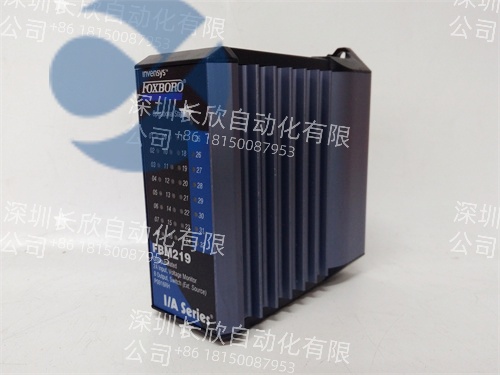

Product Overview

TheFOXBORO FBM219 P0916RHis a high-performance discrete input/output module manufactured by FOXBORO(now part of Schneider Electric),designed specifically for industrial automation control systems.This advanced fieldbus module belongs to the I/A Series distributed control system(DCS)family and serves as a critical component for receiving and transmitting discrete signal data in various industrial applications

.

As adiscrete I/O module,theFOXBORO FBM219 P0916RHfeatures 24 discrete input channels and 8 discrete output channels,providing comprehensive signal processing capabilities for industrial control systems.The module supports voltage signals ranging from 15-60V DC,120V AC/125V DC,and 240V AC,making it suitable for a wide range of industrial sensors and actuators

.

Technical Specifications

Parameter Name

Parameter Value

Product Model

FOXBORO FBM219 P0916RH

Manufacturer

FOXBORO(Schneider Electric)

Product Type

Discrete Input/Output Module

Input Channels

24 discrete inputs

Output Channels

8 discrete outputs

Supported Voltages

15-60V DC,120V AC/125V DC,240V AC

Isolation

Group isolation for each input/output

Power Supply

24V DC±5%,-10%

Power Consumption

7W maximum at 24V DC

Communication

Redundant 2 Mbps module fieldbus

Operating Temperature

-40°C to+70°C

Storage Temperature

-40°C to+85°C

Relative Humidity

5%to 95%(non-condensing)

Dimensions

10.2cm×11.4cm×4.5cm(including mounting ears)

Weight

2kg

Installation

DIN rail mounting

Protection Rating

IP20

Certification

CE,UL certified

Communication Protocols

PROFIBUS,Modbus TCP,Ethernet/IP

Processing Speed

2 Mbps fieldbus communication

Memory Type

Flash-EPROM and SRAM

I/O Capacity

24 inputs+8 outputs

Program Blocks

Supports multiple program configurations

Maximum Block Size

Configurable based on application

Reference Table Size

2K bits for discrete I/O

Main Features and Advantages

Advanced Signal Processing:TheFOXBORO FBM219 P0916RHprovides precise discrete signal processing with configurable input filter times ranging from 4ms to 32ms,ensuring reliable operation in noisy industrial environments.The module’s group isolation design prevents signal interference between channels,maintaining signal integrity and system reliability

.

Robust Industrial Design:Designed for harsh industrial environments,the module features a compact and rugged construction suitable for G3 grade(severe)environmental conditions.The module’s wide operating temperature range(-40°C to+70°C)and high humidity tolerance(5%-95%RH non-condensing)ensure stable performance in demanding industrial applications

.

Comprehensive Communication Capabilities:TheFOXBORO FBM219 P0916RHcommunicates through redundant 2 Mbps module fieldbus connections with associated FCM or FCP controllers.This redundant communication architecture ensures continuous data transmission even in the event of single communication path failure,enhancing system reliability and availability

.

Flexible Configuration Options:The module supports various configuration options including input filter time settings,fail-safe configurations,fail-safe fallback,and continuous or momentary output modes.These flexible configuration options allow the module to be tailored to specific application requirements,optimizing system performance and reliability

.

Application Field

TheFOXBORO FBM219 P0916RHfinds extensive application in various industrial sectors where reliable discrete signal processing is critical.In thechemical industry,the module is used for monitoring and controlling chemical processes,including valve position monitoring,pump status detection,and safety interlock systems.The module’s high reliability and robust design make it suitable for critical process safety applications

.

Oil and gas applicationsutilize theFOXBORO FBM219 P0916RHfor pipeline monitoring,tank level detection,and equipment status monitoring in refineries and offshore platforms.The module’s wide voltage range support(15-240V AC/DC)enables direct interface with various field devices without additional signal conditioning,simplifying system design and reducing installation costs

.

Power generation facilitiesemploy the module for monitoring critical equipment such as circuit breakers,motor starters,and protection relays.The module’s discrete input channels can monitor contact status,while the output channels can control relays and contactors for equipment protection and control functions.The module’s communication capabilities facilitate integration with DCS systems for centralized monitoring and control

.

Manufacturing applicationsbenefit from the module’s ability to monitor machine status,safety interlocks,and production line operations.The module’s compact design and DIN rail mounting capability make it suitable for space-constrained control cabinets,while its robust construction ensures reliable operation in manufacturing environments with vibration,dust,and temperature variations

.

Related Products

FOXBORO FBM216B:Digital input module with 16 channels

FOXBORO FBM218:Digital output module with 8 channels

FOXBORO FBM214:Analog input module with 8 channels

FOXBORO FCP270:Control processor module

FOXBORO FCM10E:Fieldbus communication module

FOXBORO ZCP270:Zone control processor

FOXBORO CP60:Control processor for DCS systems

FOXBORO CP40:Enhanced control processor

FOXBORO CP30:Basic control processor

Schneider Electric Modicon:PLC automation system

Siemens Simatic:PLC control system

Allen Bradley ControlLogix:High-performance PLC platform

ABB PLC:Programmable logic controller

Honeywell Experion:Process control system

Yokogawa Centum VP:Process automation system

GE Fanuc:PLC and CNC control systems

Rockwell Automation:Industrial automation solutions

HIMA F8650X:Safety controller module

Emerson DeltaV:Process automation system

Installation and Maintenance

Pre-installation Preparation:Before installing theFOXBORO FBM219 P0916RH,ensure that the installation environment meets the specified temperature and humidity requirements.Verify that the power supply meets the 24V DC input voltage requirement with sufficient current capacity.Check all mounting provisions and ensure proper grounding according to electrical codes and standards.Review system documentation to understand configuration requirements and communication settings for seamless integration into the automation system

.

Configuration and Setup:TheFOXBORO FBM219 P0916RHrequires configuration through FOXBORO’s I/A Series configuration software.Configure the input/output types,signal ranges,filter settings,and communication parameters according to the specific application requirements.The module supports various configuration options including input filter times,fail-safe settings,and output modes.Load the necessary firmware and perform initial testing to ensure proper operation

.

Maintenance Recommendations:Regular maintenance includes periodic inspection of status indicators,verification of signal integrity,and monitoring of operating temperature conditions.Perform routine calibration checks using certified calibration equipment to ensure measurement accuracy.Clean the module and surrounding area to prevent dust accumulation that could affect cooling performance.Monitor diagnostic information through the system interface and maintain current backups of configuration settings

.

Troubleshooting:In case of communication issues,check cable connections,terminal resistor settings,and protocol configurations.For signal problems,verify sensor connections,cable integrity,and calibration status.If the module shows abnormalities,check power supply connections and module connections.For persistent issues,consult the technical documentation or contact technical support for assistance.The module includes built-in diagnostic functions that can help identify and resolve common problems

.

Product Guarantee

We guarantee that everyFOXBORO FBM219 P0916RHmodule meets original manufacturer specifications and undergoes comprehensive testing before shipment.Each unit is backed by our technical support team with extensive experience in industrial automation systems and DCS applications.Our commitment to customer satisfaction includes prompt technical support,complete documentation packages,and replacement guarantees.With extensive experience in industrial control systems,we provide expert guidance from selection through installation and maintenance,ensuring your investment delivers long-term value and operational reliability

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

Leave a comment

Your email address will not be published. Required fields are marked *