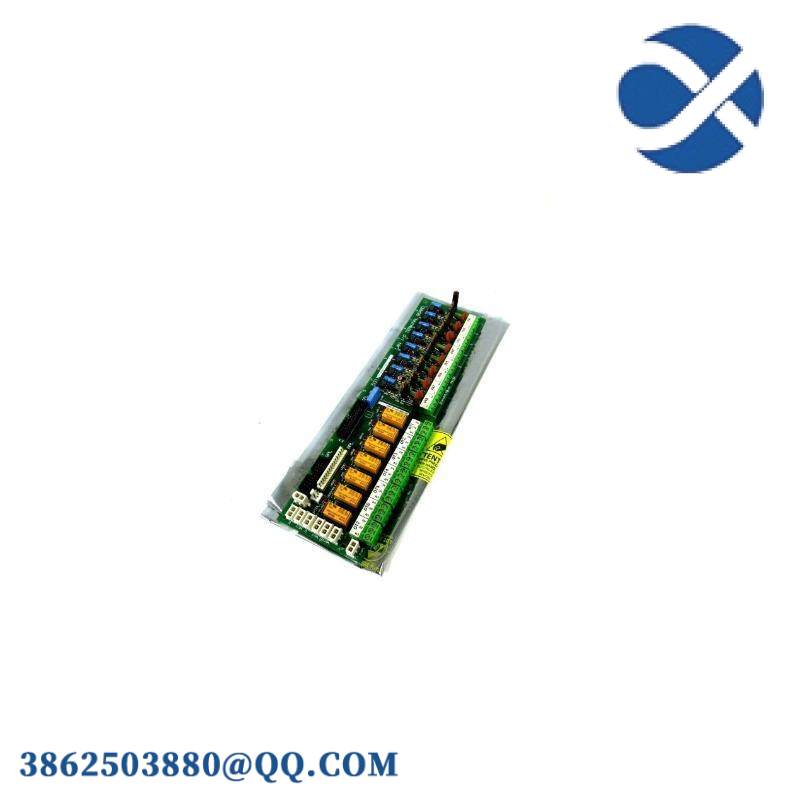

GE 531X307LTBAKG1

Product Description

The GE 531X307LTBAKG1 is a high-performance LAN Input/Output (I/O) Terminal Board designed for industrial control systems. It is part of the GE 531X series and serves as an interface system between the controlling drive and external devices. This module is specifically designed for use with GE’s EX2000 excitation systems and DC2000 drive platforms.

Product Parameters

-

Brand: GE (General Electric)

-

Model: 531X307LTBAKG1

-

Type: LAN I/O Terminal Board

-

Voltage Rating: 2 to 240V AC/DC

-

Current Rating: 10mA

-

Operating Temperature: -20°C to 60°C

-

Weight: 0.5 kg

Product Specifications

-

I/O Points:

-

Digital I/O: Supports up to 256 points

-

Analog I/O: Supports up to 64 points

-

-

Processing Speed: Scan cycle as short as 0.1 milliseconds

-

Memory Capacity: Large-capacity memory for complex control programs and data storage

-

Communication Protocols: Supports multiple protocols including EtherNet/IP, ProfiNet, DeviceNet

-

Power Requirements: 24V DC

-

Environmental Conditions:

-

Operating Temperature: 0°C to 60°C

-

Humidity: 5% to 95% (non-condensing)

-

Series

The GE 531X307LTBAKG1 belongs to the GE 531X series, known for its reliability and functionality in industrial control systems.

Features

-

Modular Design: Flexible configuration for I/O modules and communication modules

-

High Reliability: Designed for harsh industrial environments with anti-interference capabilities

-

Self-Diagnosis Function: Timely detection and handling of faults

-

Easy Programming: Supports multiple programming languages such as ladder diagrams, function block diagrams, structured text

-

Security: User authority management and data encryption

Functions

-

Real-Time Control: Manages industrial machinery and processes in real-time

-

Data Acquisition and Analysis: Collects and processes data from various sensors and devices

-

Communication: Facilitates data exchange with other devices and systems

-

Program Execution: Executes control logic and programs for automation tasks

Uses

The GE 531X307LTBAKG1 is used in various applications, including:

-

Power Generation: Monitoring and controlling power systems

-

Oil and Gas: Automated extraction and transportation

-

Water Treatment: Automated control of water treatment plants

-

Manufacturing: Controlling production lines and manufacturing processes

Application Fields

-

Power Generation

-

Oil and Gas

-

Water Treatment

-

Manufacturing

-

Other Industrial Applications

Leave a comment

Your email address will not be published. Required fields are marked *