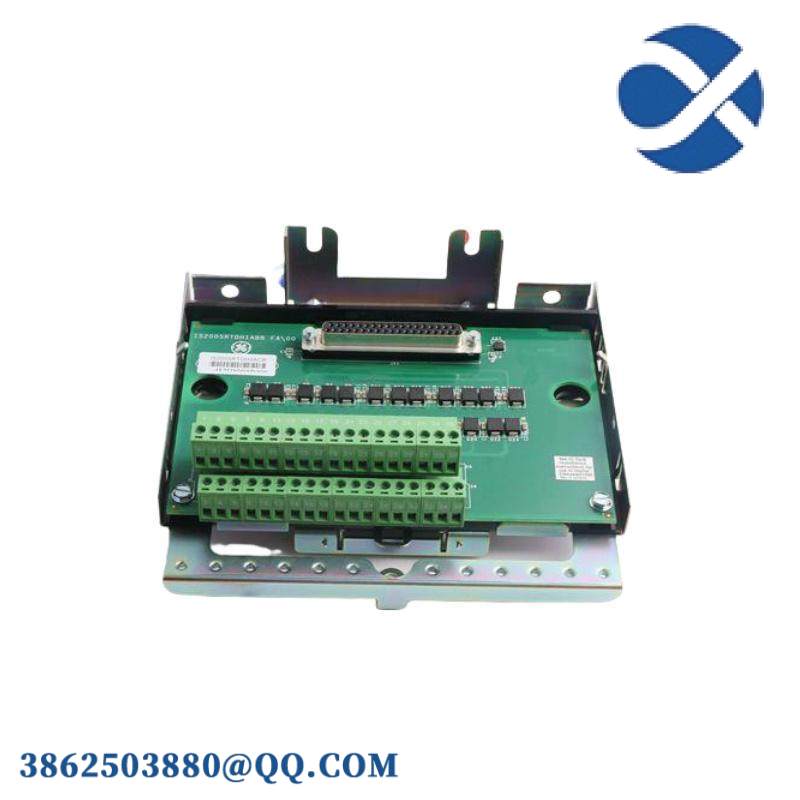

Product Description

The GE IS230SNRTH2A is a high-precision RTD (Resistance Temperature Detector) input module designed for industrial control systems, particularly for the GE Mark VIe and Speedtronic turbine control systems. It provides highly accurate temperature measurements and is ideal for critical applications in power generation, oil & gas, and industrial automation.

Product Parameters

-

Series: Mark VIe

-

Input Channels: 4 (expandable to 16 via daisy chain)

-

Input Type: RTD (2/3/4-wire, PT100/PT500)

-

Accuracy: ±0.1°C (0–100°C), ±0.2°C (-200–600°C)

-

Sampling Rate: 20 kHz (50μs per channel)

-

Operating Temperature: -40°C to +85°C

-

Power Supply: 24 VDC

-

Weight: Approximately 1 kg

-

Dimensions: 263 mm × 138 mm × 88 mm

-

Protection Level: IP65

Features

-

High Accuracy: Ensures precise temperature measurements with ±0.1°C accuracy.

-

Fast Sampling Rate: 20 kHz sampling rate captures temperature changes quickly.

-

Robust Design: IP65-rated, withstands harsh environments including offshore salt spray and high vibrations.

-

Redundancy Option: Supports dual-channel redundancy (N+1) for enhanced reliability.

-

Hot-Swap Capability: Allows maintenance without system shutdown, reducing downtime.

-

Wide Operating Range: Functions reliably in extreme temperatures (-40°C to +85°C).

Function

The IS230SNRTH2A module is used to convert RTD resistance signals into digital data for turbine control systems. It acts as a “thermal nerve center,” providing real-time temperature monitoring to prevent overheating and optimize process efficiency.

Applications

-

Power Generation: Monitors turbine blade temperatures, maintaining stability during load shifts.

-

Oil & Gas: Protects subsea pumps with real-time thermal mapping.

-

Industrial Manufacturing: Optimizes energy efficiency in steel mill furnaces.

Application Fields

-

Power Plants: Ensures stable temperature control in nuclear and thermal power plants.

-

Oil and Gas Facilities: Provides reliable temperature monitoring in offshore and onshore operations.

-

Manufacturing: Enhances process efficiency and safety in heavy industries

Leave a comment

Your email address will not be published. Required fields are marked *