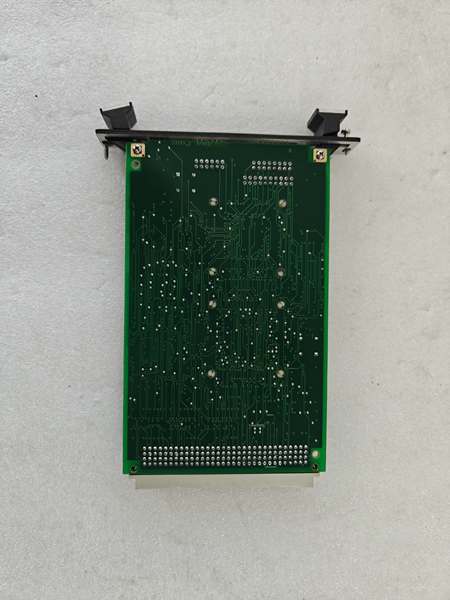

Product Description

The GE UCSC H1 IS420UCSCH1A-B is a high-performance quad-core controller module designed for industrial automation and control systems. It is part of the Mark VIe series and is specifically tailored for applications requiring high reliability, real-time processing, and advanced communication capabilities. This module is widely used in gas turbines, steam turbines, and industrial automation systems.

Product Parameters

-

Model: IS420UCSCH1A-B

-

Series: Mark VIe

-

Type: Quad-core Controller

-

Processor: 1.2 GHz AMD G-Series quad-core processor.

-

Memory: 4GB DDR3-1333 SDRAM.

-

Operating System: QNX Neutrino real-time multitasking operating system.

-

Communication Interfaces:

-

6 Ethernet ports (5 on the front panel, 1 on the bottom for Predix connectivity).

-

Supports EtherCAT, PROFINET, Modbus TCP/IP, and OPC UA.

-

-

Input Voltage: 24 VDC ±5%.

-

Operating Temperature: -40°C to 70°C.

-

Storage Temperature: -40°C to 85°C.

-

Dimensions: 19-inch standard rack installation.

-

Certifications: CE, UL, IEC 61131.

Product Specifications

-

Redundancy Configurations: Simplex, Dual.

-

NVSRAM: 3067 non-volatile program variables.

-

Protection Level: IP65 (IP67 in some scenarios).

-

Altitude for Normal Operation: 0-1000 meters.

Features

-

High-Performance Processing: Quad-core architecture ensures efficient handling of complex control tasks.

-

Real-Time Hypervisor Functionality: Supports real-time multitasking with high reliability.

-

Embedded Field Agent (EMA) Technology: Facilitates stable connections to cloud platforms like Predix for real-time data transmission.

-

Independent Operation: Does not rely on traditional backplane architecture, reducing the risk of data loss during maintenance.

-

Industrial-Grade Reliability: Designed for harsh environments with wide temperature ranges and anti-vibration capabilities.

-

Modular Expansion: Supports multiple I/O module extensions to meet complex system integration requirements.

Function

The IS420UCSCH1A-B serves as the primary controller in the Mark VIe system, providing real-time control and monitoring functions. It manages protection logic, speed control, combustion optimization, and electrical parameter monitoring for turbines and compressors. It also supports remote monitoring and data analysis through cloud platforms.

Applications

-

Gas and Steam Turbine Control: Speed control, combustion optimization, and fault protection.

-

Power Plant Automation: Real-time monitoring and control in thermal, wind, and nuclear power plants.

-

Industrial Automation: Control and optimization of compressors, pumps, and manufacturing processes.

-

Oil and Gas: Pipeline control and drilling platform automation.

-

Process Industries: Distributed control and safety interlocking in chemical and metallurgical industries.

Application Fields

-

Energy Sector: Gas turbines, steam turbines, power generation.

-

Industrial Automation: Manufacturing, process control.

-

Oil and Gas: Pipeline control, drilling platforms.

-

Process Control: Chemical, metallurgical industries.

-

Smart Buildings and Transportation: Building energy management, traffic signal control

Leave a comment

Your email address will not be published. Required fields are marked *