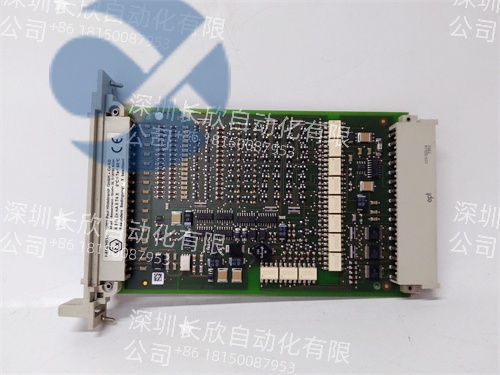

Product Overview

The HIMA F3236 is a high-performance safety system controller manufactured by HIMA,a global leader in industrial safety technology.This advanced module represents a critical component in safety instrumented systems(SIS),designed specifically for applications requiring the highest levels of functional safety and reliability.TheHIMA F3236serves as the central processing unit in safety-critical applications,providing robust protection for personnel,equipment,and the environment in hazardous industrial processes.

As part of HIMA’s comprehensive safety system portfolio,theF3236controller incorporates state-of-the-art safety technology and meets rigorous international standards including SIL 3 according to IEC 61508 and IEC 61511.The module’s robust architecture features redundant processing channels and comprehensive self-diagnostic capabilities,ensuring continuous operation even in the most demanding industrial environments.TheHIMA F3236is engineered to handle complex safety functions including emergency shutdown(ESD),fire and gas detection(F&G),and burner management systems(BMS)with maximum reliability.

The strategic importance of theHIMA F3236lies in its ability to provide fail-safe operation in critical protection scenarios.The controller’s design emphasizes deterministic response times and comprehensive fault detection mechanisms,making it suitable for applications where system availability and safety integrity are paramount.TheHIMA F3236offers flexible configuration options and extensive communication capabilities,enabling seamless integration with various process control systems while maintaining complete safety independence.

Technical Specifications

Parameter Name

Parameter Value

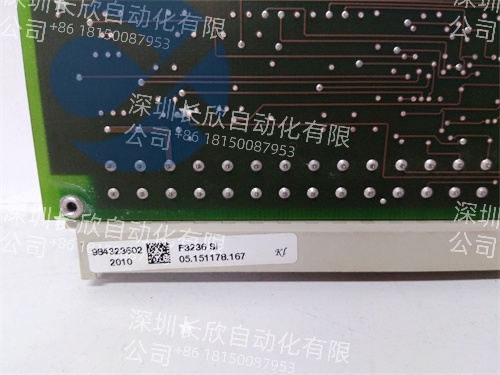

Product Model

F3236

Manufacturer

HIMA

Product Type

Safety System Controller

Safety Level

SIL 3(IEC 61508/61511)

Processor Type

Dual/Quad redundant architecture

Memory Capacity

2MB SRAM,4MB Flash

Operating Temperature

-40°C to+70°C

Storage Temperature

-40°C to+85°C

Power Supply

24V DC±10%

Power Consumption

15W typical

Input/Output Capacity

Up to 1024 I/O points

Communication Ports

Ethernet,RS-485,PROFIBUS DP

Response Time

<100ms typical

MTBF

>100 years calculated

Diagnostic Coverage

>99%

Hardware Fault Tolerance

HFT=1

Certifications

TÜV,IEC 61508,IEC 61511

Dimensions

200mm×150mm×80mm

Weight

1.2kg

Installation

DIN rail mounting

Protection Rating

IP20

Main Features and Advantages

High Safety Integrity:TheHIMA F3236delivers exceptional safety performance through its redundant processor architecture and comprehensive self-diagnostic capabilities.The controller’s dual or quad redundant design ensures continuous operation even in the event of component failures,maintaining system availability while meeting SIL 3 requirements.TheHIMA F3236features advanced diagnostic functions that continuously monitor hardware integrity,detecting faults in processors,memory,and I/O interfaces with diagnostic coverage exceeding 99%.This high level of fault detection ensures that any potential failure is identified and handled appropriately,preventing dangerous undetected failures in safety-critical applications.

Robust Communication and Integration:This safety controller features comprehensive communication capabilities supporting multiple industrial protocols including Ethernet,PROFIBUS DP,and Modbus TCP.TheHIMA F3236enables seamless integration with various distributed control systems(DCS)while maintaining complete safety independence.The controller’s communication interfaces employ time-stamping and CRC checking mechanisms to ensure data integrity and prevent communication errors.TheHIMA F3236supports redundant communication paths and automatic switchover,enhancing system availability and ensuring continuous safety protection.

Flexible Application Programming:TheHIMA F3236offers versatile programming options using HIMA’s proven safety development environment.The controller supports function block diagram(FBD)and ladder logic(LD)programming languages specifically designed for safety applications.TheHIMA F3236includes comprehensive application libraries with pre-certified function blocks for common safety functions,reducing engineering time and validation efforts.The controller’s modular design allows for flexible configuration and expansion,supporting various I/O types including digital inputs/outputs,analog inputs,and pulse inputs for different application requirements.

Application Field

Oil and Gas Industry represents the primary application domain for theHIMA F3236,particularly in offshore platforms,refineries,and pipeline operations.In offshore drilling platforms,the controller manages emergency shutdown systems(ESD)that protect against well control incidents and process upsets.TheHIMA F3236’s robust design and high reliability make it essential for fire and gas detection systems(F&G)that safeguard personnel and equipment in potentially explosive atmospheres.In pipeline transportation systems,the controller provides overpressure protection and leak detection functions,ensuring safe operation of critical infrastructure.

Chemical and Petrochemical Plants extensively utilize theHIMA F3236for process safety applications.In chemical reactors and distillation columns,the controller implements safety interlocks that prevent runaway reactions and equipment damage.TheHIMA F3236’s high diagnostic coverage and fault tolerance capabilities make it suitable for handling toxic chemical processes where failure could have severe consequences.In storage tank farms,the controller manages overfill protection systems and fire prevention measures,ensuring safe storage of hazardous materials.

Power Generation Facilities leverage theHIMA F3236for critical protection functions.In gas turbine power plants,the controller implements burner management systems(BMS)that ensure safe startup,operation,and shutdown of combustion equipment.TheHIMA F3236’s fast response time and deterministic behavior make it ideal for turbine overspeed protection and vibration monitoring applications.In nuclear power plants,the controller provides safety-grade protection functions that meet rigorous regulatory requirements for nuclear safety systems.

Related Products

HIMA F3237:Enhanced version with increased processing capacity

HIMA F3238:High-density version with expanded I/O capabilities

HIMA F3235:Compact version for space-constrained applications

HIMA F3230:Basic safety controller for SIL 2 applications

HIMA F3239:Advanced version with additional communication options

HIMA F3240:Next-generation safety controller with upgraded features

HIMA F3250:High-availability version for critical applications

HIMA F3260:Specialized version for specific industry requirements

HIMA F3270:Enhanced communication version

HIMA F3280:Latest generation with advanced safety features

Installation and Maintenance

Pre-installation preparation:Proper installation of theHIMA F3236requires careful planning and adherence to safety system engineering standards.Before installation,verify that the control cabinet provides adequate space for proper ventilation and maintenance access,with appropriate clearances around the module.Ensure the DIN rail is properly secured and that the mounting surface is clean and free from contaminants.Check that the power supply meets the controller’s requirements(24V DC±10%)and verify proper grounding connections.All field wiring should use appropriate cable types and follow separation guidelines to prevent electrical interference.TheHIMA F3236should be handled with care to avoid damage to connectors and components,and static discharge precautions should be observed during installation.

Maintenance recommendations:Regular maintenance of theHIMA F3236focuses on ensuring optimal safety performance through systematic testing and inspection.Establish a preventive maintenance schedule that includes quarterly visual inspections for signs of damage,contamination,or loose connections.Perform regular function testing of safety functions to verify proper operation and maintain safety integrity.TheHIMA F3236’s comprehensive diagnostic system should be monitored continuously for any fault indications.Keep detailed records of all maintenance activities,function tests,and any operational issues encountered.The modular design of theHIMA F3236facilitates easy replacement if necessary,minimizing system downtime during maintenance operations while maintaining safety protection.

Product Guarantee

We guarantee that theHIMA F3236meets all manufacturer specifications and safety performance requirements for SIL 3 applications.Our comprehensive quality assurance process includes rigorous testing and validation procedures to ensure reliable operation in demanding industrial environments.We provide complete technical support covering system configuration,safety engineering guidance,and operational troubleshooting to ensure successful implementation of theHIMA F3236in your safety instrumented system.Our commitment extends throughout the product lifecycle,with ongoing support for safety performance optimization and maintenance planning.We maintain adequate inventory of critical components to support urgent requirements and offer replacement services for defective units within warranty terms,ensuring continuous safety protection of your industrial processes.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

Leave a comment

Your email address will not be published. Required fields are marked *