Product Overview

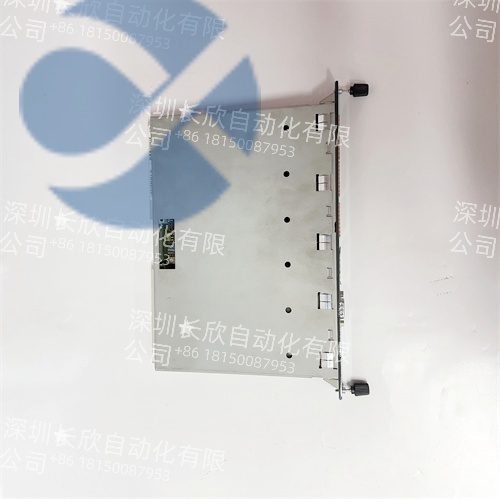

The HIMA FB201 is an entry-level safety input/output module developed by HIMA,tailored for small-to-medium safety instrumented systems(SIS)and machine safety applications.As a cost-effective component of HIMA’s HIMatrix controller ecosystem—particularly compatible with compact models like the HIMatrix F35—it delivers reliable monitoring and control capabilities for low-to-moderate risk scenarios,such as small chemical tanks,food processing lines,and water treatment facilities.Unlike high-end modules like the F7123,the FB201 focuses on essential safety functions with simplified configuration,making it accessible for applications where SIL 3 integrity is not mandatory.

At its core,the HIMA FB201 is designed for digital signal processing,typically supporting 24V DC digital inputs(for devices like safety gate switches,emergency stop buttons)and digital outputs(for driving alarm buzzers,small shutdown valves).It adheres to IEC 61508 SIL 2 certification and holds TÜV approval,ensuring compliance with global safety standards for scenarios where failure could cause minor equipment damage or process disruption(rather than catastrophic incidents).For example,in a bottled water plant’s SIS,the FB201 monitors 4 level sensors(digital inputs)on storage tanks;if water level drops below the minimum threshold,it triggers 2 feed pump relays(digital outputs)within 50ms,preventing pump dry-running and equipment wear.

Compared to HIMA’s high-performance F7123,the FB201 offers a streamlined feature set:it omits advanced redundancy but retains core self-diagnostics(e.g.,open-circuit detection for input channels)to ensure basic fault coverage.This balance of safety and cost makes it a preferred choice for industries where budget constraints coexist with regulatory safety requirements—such as a small-scale pharmaceutical blending system,where the FB201 has maintained continuous operation for 3+years with zero safety-related downtime.

Technical Specifications

Parameter Name

Parameter Value

Product Model

HIMA FB201

Manufacturer

HIMA Paul Hildebrandt GmbH&Co.KG

Product Type

Entry-Level Safety Digital I/O Module for SIS

Compatible Controllers

HIMA HIMatrix F35,HIMatrix F36(compact variants)

Safety Certification

IEC 61508 SIL 2(hardware/software);TÜV Rheinland Approved;EN ISO 13849-1 PL d

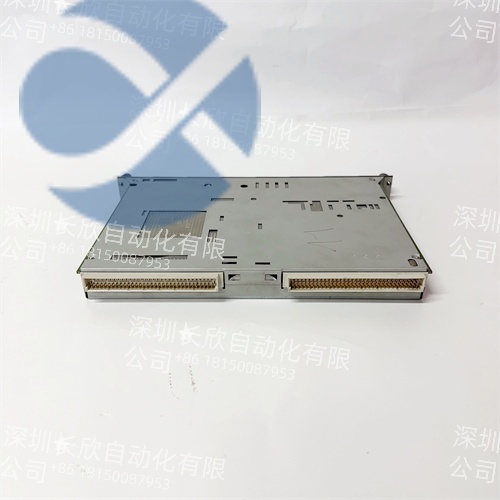

I/O Configuration

16 Digital Inputs(DI):24V DC(sinking);8 Digital Outputs(DO):24V DC(1A per channel)

Input Accuracy

Digital:±1.0V(threshold for 24V DC)

Response Time

Input Channel:≤10ms;Output Channel:≤20ms(from input trigger to output action)

Operating Temperature

-10℃to+55℃(operation);-40℃to+80℃(storage)

Hazardous Area Certifications

ATEX Zone 22(II 3D Ex tc IIIC T4 Da),IECEx Zone 22(Ex tc IIIC T4 Da)

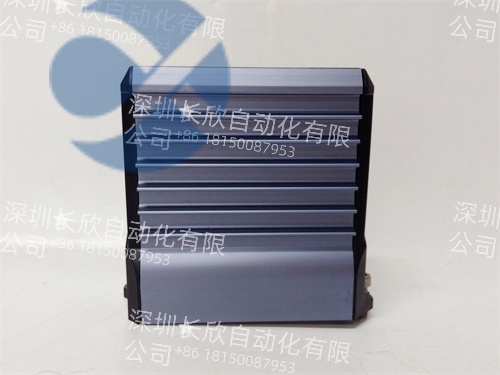

Power Supply

24V DC±15%(20.4V–27.6V);Power Consumption:≤8W

Physical Dimensions

80mm(L)×120mm(W)×180mm(H);Rack-Mountable(2U Form Factor)

Weight

0.8kg(1.76 lbs)

Redundancy

No built-in redundancy;Supports single-channel safety loops

Communication

Backplane:HIMA Local Bus(HLB)–50Mbps;No remote I/O support

Diagnostics

Channel-level open-circuit detection,overcurrent protection,power fault alert

Ingress Protection

IP20(suitable for control cabinet installation)

EMI/RFI Immunity

IEC 61000-4-2(ESD±4kV contact),IEC 61000-4-3(Radiated Immunity±3V/m)

Main Features and Advantages

SIL 2 Certification for Targeted Safety Needs:The HIMA FB201 is certified to IEC 61508 SIL 2,addressing the needs of applications where the probability of failure on demand(PFD)must be≤10⁻²—typical for low-to-moderate risk scenarios like packaging line safety or small tank level control.This certification is validated through essential testing,including temperature stress and basic fault injection,ensuring compliance without the premium cost of SIL 3 modules.A snack food manufacturer uses the FB201 in its fryer safety system:the module monitors 6 temperature limit switches(digital inputs)and triggers a heating element shutdown(digital output)if oil temperature exceeds 200℃.The SIL 2 rating meets FDA regulations for food safety while reducing hardware costs by 30%compared to SIL 3 alternatives.

Cost-Effective Design for Small-Scale Systems:Optimized for budget-conscious applications,the FB201 eliminates non-essential features like hot-swappability and redundant power,focusing on core I/O functionality.Its 16 digital inputs and 8 digital outputs cover most small SIS requirements,avoiding the need for multiple modules.A municipal water treatment plant replaced 2 generic I/O modules with a single FB201 in its chlorine dosing safety system,cutting wiring costs by 25%and simplifying maintenance.The module’s compatibility with HIMA’s SILworX software(same platform as F7123)also reduces training time for technicians familiar with HIMA ecosystems.

Compact Form Factor for Space-Constrained Installations:With a 2U rack-mount design and lightweight construction(0.8kg),the FB201 fits into small control cabinets—critical for facilities with limited space,such as modular chemical reactors or mobile processing units.A portable asphalt mixing plant integrated 4 FB201 modules into its SIS,monitoring aggregate level sensors and controlling discharge valves without expanding the cabinet footprint.The module’s IP20 rating ensures protection against dust accumulation in industrial environments,maintaining reliability in harsh conditions.

Simplified Diagnostics for Easy Maintenance:While lacking advanced drift monitoring,the FB201 includes essential diagnostics to detect common faults:open circuits in input wiring,overcurrent in output channels,and power supply irregularities.When a fault is detected,the module sends an alert to the HIMatrix controller,which triggers a local alarm light—allowing technicians to identify issues in minutes.A small cosmetic chemical plant leveraged this feature when a safety gate switch wire broke:the FB201 detected the open circuit and disabled the mixing motor,preventing operator injury and avoiding a 2-hour production delay.

Application Field

The HIMA FB201 excels in small-scale industrial applications where safety requirements are moderate but regulatory compliance is mandatory.In food and beverage manufacturing,it protects processing lines from overheating or contamination:a bakery uses the module to monitor 8 oven temperature limit switches(digital inputs)and control 4 conveyor stop relays(digital outputs).If oven temperature exceeds 250℃,the FB201 shuts down the conveyor within 30ms,preventing burnt products and fire risks—all while meeting EU CE safety standards.

Water and wastewater treatment facilities rely on the FB201 for chemical dosing and tank level control:a regional wastewater plant deployed 6 FB201 modules in its SIS,monitoring chlorine tank levels(via float switches)and controlling dosing pumps.The module’s SIL 2 certification ensures compliance with EPA regulations,while its low power consumption(≤8W)reduces energy costs for continuous operation.When a tank level dropped to 10%capacity,the FB201 triggered a refill alarm and paused the dosing pump,avoiding chemical shortages that could disrupt treatment processes.

Small chemical plants use the FB201 for batch reactor safety:a specialty adhesive manufacturer uses the module to monitor 4 pressure switches(digital inputs)and 2 emergency vent valves(digital outputs)on a 500L reactor.If pressure exceeds 10 bar,the FB201 opens the vent valves and shuts down the feed pump—preventing reactor overpressure without the expense of a SIL 3 system.The module’s compatibility with HIMatrix F35 controllers also allows seamless integration with the plant’s SCADA system,enabling remote status monitoring.

Pharmaceutical blenders and mixers benefit from the FB201’s simplified safety control:a generic drug manufacturer uses the module to monitor safety interlocks on blender lids(digital inputs)and control mixer motors(digital outputs).The FB201 ensures the mixer cannot operate unless all lids are secured,meeting FDA cGMP requirements for operator safety and product integrity.Its TÜV approval also simplifies regulatory audits,reducing compliance paperwork by 40%.

Related Products

HIMA HIMatrix F35:Compact safety controller optimized for the FB201;supports up to 8 FB201 modules for small SIS(e.g.,bakery safety systems).

HIMA F7123:High-performance counterpart to the FB201;offers SIL 3 certification and redundancy for critical applications(e.g.,offshore oil platforms).

HIMA FB202:Analog variant of the FB201;8 4-20mA inputs for applications requiring continuous variable monitoring(e.g.,temperature sensors).

HIMA SILworX:Configuration software for the FB201;enables graphical programming of safety logic(e.g.,”if lid open,stop mixer”)without coding.

HIMA HMI Basic View:Entry-level human-machine interface for FB201 systems;displays safety loop status and alarm messages(e.g.,low tank level).

HIMA Power Supply PS100:24V DC power unit for FB201 modules;provides stable power for small SIS(e.g.,wastewater treatment plants).

HIMA Cable Kit CK-FB201:Pre-wired cable set for FB201 installation;reduces wiring time by 50%for control cabinet integration.

HIMA Diagnostic Tool DT10:Handheld device for FB201 troubleshooting;tests input/output channels and verifies communication with HIMatrix controllers.

Installation and Maintenance

Pre-installation preparation:Before installing the HIMA FB201,confirm compatibility with the HIMatrix F35/F36 controller(firmware version≥V4.0)and verify field devices match the module’s I/O specifications(24V DC,sinking inputs).Inspect the module for physical damage(e.g.,damaged connectors,cracked housing)and ensure accessories(mounting clips,wiring diagrams)are included.Install the FB201 in a 2U rack within a control cabinet,maintaining a minimum of 5cm clearance from heat sources(e.g.,power supplies)to prevent overheating.

Wiring and configuration:Use 24AWG unshielded cables for digital inputs(maximum length:50m)and connect to safety devices with single-wiring(redundant paths optional for critical loops).Digital outputs should use 20AWG cables(to handle 1A current)and include a 1A fuse per channel to prevent overcurrent damage.Configure the FB201 via SILworX software:assign input channels to safety devices(e.g.,E-Stop button to DI1),set output actions(e.g.,DO1 to conveyor stop relay),and enable basic diagnostics(open-circuit detection).Test each channel with a 24V DC signal generator to verify functionality before integrating with the live SIS.

Maintenance recommendations:Conduct quarterly visual inspections of the FB201—check for loose wiring,dust buildup on connectors(clean with a dry cloth),and LED status(green=normal,red=fault).Every 6 months,use SILworX to run a diagnostic test:verify input detection,output activation,and communication with the HIMatrix controller.Replace fuses immediately if an output channel fails to operate(use only HIMA-approved 1A fuses to maintain safety certification).

Troubleshooting tips:If the FB201 shows a red fault LED,first check power supply voltage(must be 20.4V–27.6V).If power is normal,use SILworX to identify the faulty channel(e.g.,open circuit on DI3)and inspect wiring connections.For unresponsive outputs,test the fuse and replace if blown.If communication fails,verify the backplane connection to the HIMatrix controller and restart the controller if necessary.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

Leave a comment

Your email address will not be published. Required fields are marked *