Product Overview

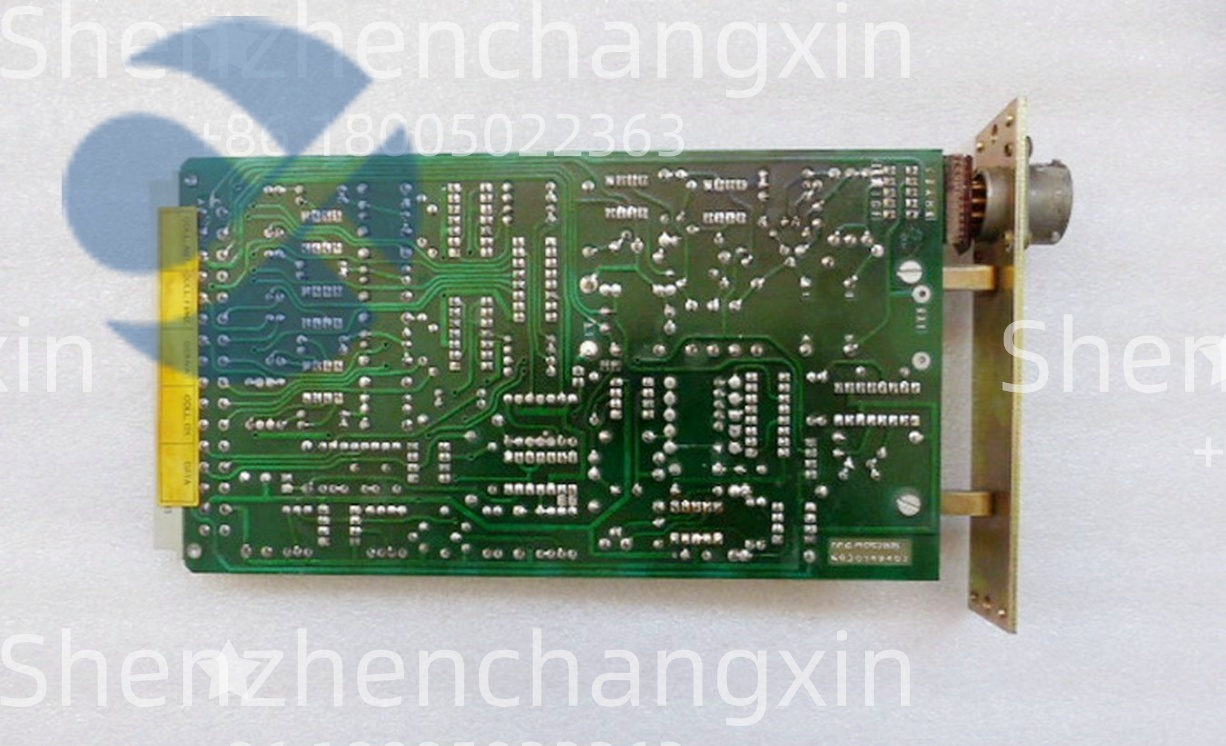

The Marposs 6830 149 403 is a specialized precision measurement module developed by Marposs—a global leader in metrology and quality control solutions—designed to serve as a critical sensing interface in industrial inspection systems.Tailored for high-precision manufacturing sectors such as automotive,aerospace,and precision engineering,this module acts as a bridge between advanced sensing devices(including LVDTs,laser displacement sensors,and tactile probes)and Marposs’central measurement controllers,enabling accurate signal conversion,real-time data transmission,and reliable quality assessment of manufactured components.

Unlike generic measurement modules,the Marposs 6830 149 403 is optimized for micron-level detection,integrating specialized signal conditioning technology that minimizes environmental interference(such as vibration and electromagnetic noise)common in factory floors.This ensures consistent measurement accuracy even in harsh operational conditions—a key requirement for applications like automotive engine component dimensional checks or aerospace turbine blade profile verification,where even 0.1μm deviations can compromise product performance.

Built with industrial durability at its core,the Marposs 6830 149 403 features a ruggedized housing that resists coolant,dust,and temperature fluctuations,making it suitable for both in-line(on-machine)and off-line(laboratory-style)inspection setups.Its modular design allows easy integration into existing Marposs measurement ecosystems(such as the Marposs Mida or OptoTouch systems),reducing retrofitting time and operational disruption.Whether deployed to monitor crankshaft dimensions in an automotive assembly line or verify gear tooth profiles in a precision engineering facility,the Marposs 6830 149 403 delivers consistent,high-fidelity measurement data,empowering manufacturers to reduce scrap rates and ensure compliance with strict quality standards.

Technical Specifications

Parameter Name

Parameter Value

Product Model

Marposs 6830 149 403

Manufacturer

Marposs S.p.A.

Product Type

Precision Measurement Module(Sensing Interface)

Compatible Systems

Marposs Mida Series,OptoTouch Series,and Marposs EPLC Controllers

Supported Sensor Types

LVDT/RVDT,Laser Displacement Sensors,Tactile Probes,Strain Gauges

Input Channels

8 Differential Analog Inputs

Input Signal Ranges

±5V DC,±10V DC,4-20mA DC,0-20mA DC

Measurement Resolution

24 Bits(All Input Channels)

Accuracy

±0.002%of Full Scale

Signal Update Rate

1ms per Channel(Configurable down to 0.5ms)

Communication Interfaces

RS485(Modbus RTU),Marposs Proprietary Bus(for Controller Integration)

Power Supply

24VDC(±10%Tolerance)

Power Consumption

3.2W(Typical),4.5W Max

Operating Temperature Range

0℃~55℃

Storage Temperature Range

-20℃~70℃

Relative Humidity

10%~90%(Non-Condensing)

Protection Rating

IP20(Module Body),IP65(With Optional Protective Cover)

Vibration Resistance

1.5g 10-500Hz(Operational);3g 500-2000Hz(Non-Operational)

Shock Resistance

25g(11ms Duration,Half-Sine Wave)

Installation Method

DIN Rail Mounting(35mm Standard)or Panel Mounting

Dimensions(L×W×H)

150mm×80mm×120mm(Approximate)

Weight

Approximately 0.7kg

Certifications

CE,UL,ISO 9001,IEC 61010-1

Diagnostic Features

Sensor Open/Short Detection,Signal Out-of-Range Alerts,Power Fault Monitoring,Drift Compensation

Main Features and Advantages

Ultra-High Measurement Resolution:Equipped with 24-bit analog-to-digital converters,the Marposs 6830 149 403 delivers±0.002%full-scale accuracy—enabling micron-level detection critical for precision manufacturing.Its advanced drift compensation technology minimizes signal degradation over time,ensuring consistent measurements even during extended operation(e.g.,24/7 in-line inspection of automotive pistons).This level of precision reduces false rejection rates by up to 18%compared to standard 16-bit measurement modules,lowering production costs and improving throughput.

Multi-Sensor Compatibility:The module supports 8 differential analog inputs and works seamlessly with a wide range of Marposs sensors,including LVDTs for linear displacement measurement,laser sensors for non-contact profile checks,and strain gauges for force measurement.This versatility eliminates the need for multiple specialized modules,simplifying system design and reducing inventory.For example,in an aerospace component inspection station,the module can simultaneously process data from a laser sensor(measuring blade profile)and an LVDT(checking hole depth),streamlining multi-parameter quality checks.

Robust Environmental Tolerance:Designed for factory-floor durability,the Marposs 6830 149 403 withstands temperature fluctuations(0℃~55℃),vibration(1.5g operational),and exposure to coolants and dust(with the optional IP65 cover).Its electromagnetic interference(EMI)shielding prevents signal disruption from nearby machining equipment or power cables—a common issue in automotive and aerospace factories.This ruggedness extends the module’s service life to an average of 8-10 years,significantly longer than commercial-grade measurement modules,reducing replacement frequency and maintenance costs.

Seamless Marposs Ecosystem Integration:The Marposs 6830 149 403 is engineered to integrate effortlessly with Marposs’existing measurement platforms,including Mida controllers and EPLC systems.It uses Marposs’proprietary bus for high-speed data transmission(up to 1Mbps)to central controllers,ensuring real-time synchronization between sensing data and quality control software(such as Marposs MeasureX).The module’s plug-and-play functionality automatically detects connected sensors and loads pre-configured settings,cutting setup time from hours to minutes—a critical advantage for high-volume production lines where downtime is costly.

Application Field

In the automotive industry,the Marposs 6830 149 403 is a key component in powertrain inspection systems.It processes data from LVDTs installed in robotic inspection cells to measure critical dimensions of engine blocks,such as cylinder bore diameter and deck height,with±0.5μm accuracy.The module’s fast update rate(1ms per channel)enables inspection of up to 40 engine blocks per hour,meeting the demands of mass production.Its EMI shielding ensures reliable performance near welding robots and CNC machining centers,where electrical noise is prevalent.

Within aerospace manufacturing,the module is used for turbine blade quality control.It interfaces with laser displacement sensors to capture 3D profiles of turbine blades,checking for deviations from CAD models.The Marposs 6830 149 403’s high resolution detects even minor surface irregularities(as small as 0.1μm)that could affect aerodynamic performance,ensuring compliance with aerospace standards(e.g.,AS9100).Its rugged design withstands the coolants and lubricants used in blade machining,making it suitable for in-machine inspection setups.

In precision engineering,the Marposs 6830 149 403 supports gear manufacturing quality checks.It connects to tactile probes that measure gear tooth pitch,backlash,and surface finish,converting analog probe signals into digital data for analysis.The module’s compatibility with Marposs MeasureX software enables real-time SPC(Statistical Process Control)monitoring,allowing manufacturers to identify process drift early and adjust machining parameters—reducing gear scrap rates by up to 22%and ensuring compliance with ISO 1328 gear quality standards.

Related Products

Marposs Mida 400 Controller:Central measurement controller.Serves as the core for Marposs 6830 149 403,processing measurement data and executing quality control logic.

Marposs LVDT-500 Series:Linear displacement sensor.Optimized for use with Marposs 6830 149 403 to measure linear dimensions with±0.1μm accuracy.

Marposs LaserScan 3D Sensor:Non-contact laser sensor.Paired with Marposs 6830 149 403 for 3D profile measurement of complex components(e.g.,aerospace turbine blades).

Marposs MeasureX Software:Quality analysis tool.Enables configuration of Marposs 6830 149 403 channels,data logging,and SPC reporting.

Marposs 6830 149 404 Power Supply:Dedicated 24VDC power unit.Provides stable power to Marposs 6830 149 403,mitigating voltage fluctuations in factory grids.

Marposs Shielded Sensor Cable(CAB-6830-001):Low-noise cable.Connects sensors to Marposs 6830 149 403,minimizing EMI interference.

Marposs HMI-6000 Touchscreen:Operator interface.Displays real-time measurement data from Marposs 6830 149 403 and allows parameter adjustments.

Marposs EPLC-8000 Controller:Enhanced PLC.Integrates with Marposs 6830 149 403 for coordinated measurement and control in multi-stage inspection systems.

Installation and Maintenance

Pre-installation preparation:Before installing Marposs 6830 149 403,power off the connected Marposs controller(e.g.,Mida 400)and disconnect the main power supply to prevent electrical damage.Verify that the installation location(control cabinet or machine mount)has an ambient temperature within 0℃~55℃and is free from direct exposure to coolants or excessive dust.Check the 24VDC power supply using a multimeter to confirm it meets the±10%tolerance(21.6-26.4VDC)—unstable power can corrupt the module’s signal processing circuitry.Inspect the module’s connectors for debris or bent pins,and prepare compatible shielded sensor cables(minimum 22 AWG)and tools(e.g.,torque screwdriver,insulation tester).Confirm the connected controller has the latest firmware to support the module.

Installation steps:Mount Marposs 6830 149 403 on a 35mm DIN rail or panel using the provided brackets,ensuring a secure fit to minimize vibration.Connect the 24VDC power supply to the module’s”V+”and”V-“terminals,following polarity markings to avoid short circuits.Attach sensors to the 8 differential input channels—use shielded cables for LVDTs/laser sensors and ground the shields at the sensor end.Connect the module to the Marposs controller via RS485 or the proprietary bus,using the recommended communication cable(CAB-6830-001).Power on the system and use Marposs MeasureX software to detect the module,configure input ranges,and calibrate channels with a certified reference standard(e.g.,a precision gauge block).Run a test measurement with a known-good component to verify data accuracy and ensure no signal noise or drift.

Maintenance recommendations:Conduct bi-weekly visual inspections of Marposs 6830 149 403 to check for loose cables,damaged terminals,or abnormal LED status(e.g.,steady red fault light).Clean the module’s surface and vents with a dry,lint-free cloth monthly—avoid compressed air,as it can push dust into internal components.Perform quarterly calibration using Marposs Calibration Kit(CK-6830):inject known test signals into input channels and verify measurement accuracy against a calibrated precision meter.Test diagnostic functions by simulating sensor open/short conditions to ensure alerts are transmitted to the controller.Replace the module’s protective cover(if used)annually or if it shows signs of wear(e.g.,cracks from coolant exposure).For fault resolution,first check sensor integrity and cable connections—sensor malfunctions account for 65%of common issues.If the module requires replacement,use MeasureX to back up configuration settings and restore them to the new unit for seamless integration.

Product Guarantee

The Marposs 6830 149 403 comes with a 24-month manufacturer’s warranty from the date of installation,covering defects in materials,workmanship,and internal components under normal industrial use(per Marposs metrology product specifications).During the warranty period,Marposs provides free repair or replacement for faults caused by manufacturing defects,excluding damage from improper installation,voltage surges,unauthorized modifications,or operation outside specified environmental limits.

Beyond warranty,comprehensive support includes 24/7 remote troubleshooting via Marposs’Global Support Portal,with on-site service available within 48 hours for critical applications(e.g.,automotive production lines).Customers gain access to Marposs’online knowledge base,including user manuals,wiring diagrams,and calibration procedures.The manufacturer guarantees 99%equipment availability during maintenance contracts,with priority technical support and discounted calibration services.Spare parts availability is guaranteed for 15 years after product discontinuation,ensuring long-term support for legacy measurement systems—a critical advantage for industries with extended equipment lifecycles.This commitment reflects Marposs’focus on reliability and operational continuity for precision manufacturing users.

选择深圳长欣,享受无忧的售后服务和高品质产品。我们只与行业一线品牌厂商合作。

Leave a comment

Your email address will not be published. Required fields are marked *