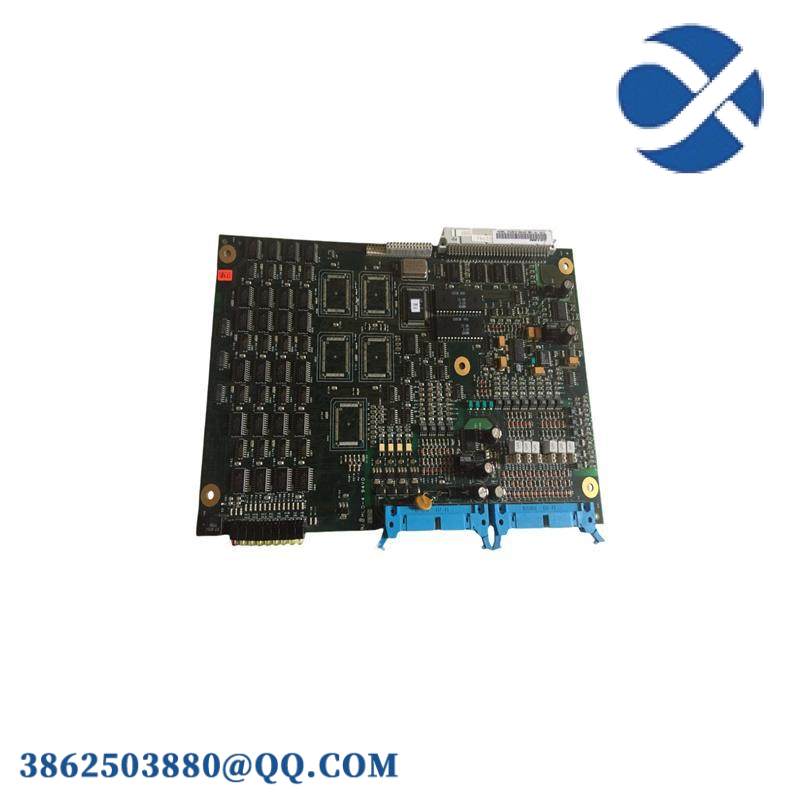

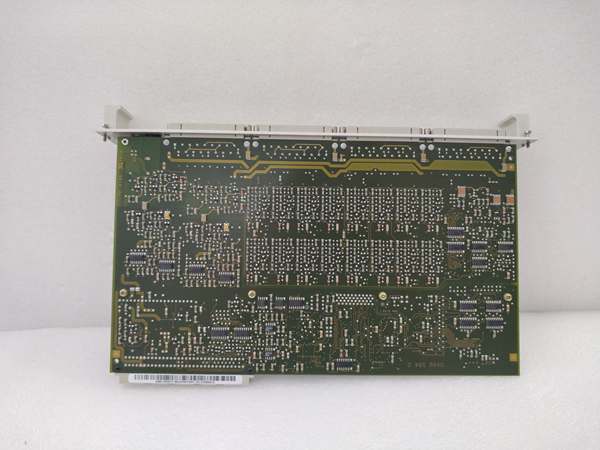

ABB V4550220-0100

Product Description

The ABB V4550220-0100 is a high-precision controller/processor module designed for industrial automation and control systems. It is widely used for signal acquisition, processing, and equipment control in various industrial applications, including manufacturing, process control, and distributed control systems (DCS). This module is known for its high precision, reliability, and flexibility in industrial environments.

Product Parameters

-

Operating Voltage: 24V DC

-

Input/Output: Supports multiple signal types (analog and digital), with specific configurations depending on application requirements

-

Communication Interfaces: Supports Modbus, Profibus, and other industrial protocols

-

Operating Temperature: 0°C to 85°C

-

Protection Level: Industrial-grade protection suitable for harsh environments

-

Dimensions: Compact design (e.g., 16mm × 25mm × 12mm), exact dimensions may vary

-

Weight: Approximately 0.18 kg

Product Specifications

-

High-Precision Control: Utilizes advanced control algorithms to ensure high-precision signal processing and equipment control.

-

Modular Design: Easy to install and integrate into existing systems, with a user-friendly interface and programming tools.

-

Reliability: Manufactured with high-quality materials and advanced technology to ensure long-term stable operation.

-

Redundancy: Supports redundant design to enhance system reliability.

-

Flexibility: Supports multiple communication protocols and interfaces, and can be customized to meet different application needs.

Series

The V4550220-0100 belongs to the ABB Freelance DCS series, designed for industrial automation and control systems.

Features

-

High Precision: Capable of high-precision control suitable for complex industrial applications.

-

Ease of Use: Simple and intuitive interface, making installation and operation straightforward.

-

Wide Applicability: Used in manufacturing, automation, chemical plants, metallurgy, and more.

-

Energy Efficiency: Optimized design to reduce energy consumption, supporting green manufacturing.

Functions

-

Signal Processing: Collects and processes signals from sensors and other devices for system control.

-

Control Logic Execution: Manages complex control logic for precise process control.

-

Communication: Facilitates data exchange with other devices via supported communication protocols.

-

Remote Monitoring: Supports remote monitoring and diagnosis.

Uses

-

Industrial Automation: Improves production efficiency and quality on automated production lines.

-

Process Control: Monitors and controls processes in industries such as chemicals, oil, and power.

-

Distributed Control Systems (DCS): Serves as a core control module for centralized monitoring and decentralized control.

Application Fields

-

Manufacturing: Enhances efficiency in production lines and robotic systems.

-

Power Generation: Ensures stable operation in power plants.

-

Chemical Processing: Controls complex production processes.

-

Oil and Gas: Manages pumps and compressors in oil fields and refineries.

-

Water and Wastewater: Controls pumps and blowers in water treatment plants