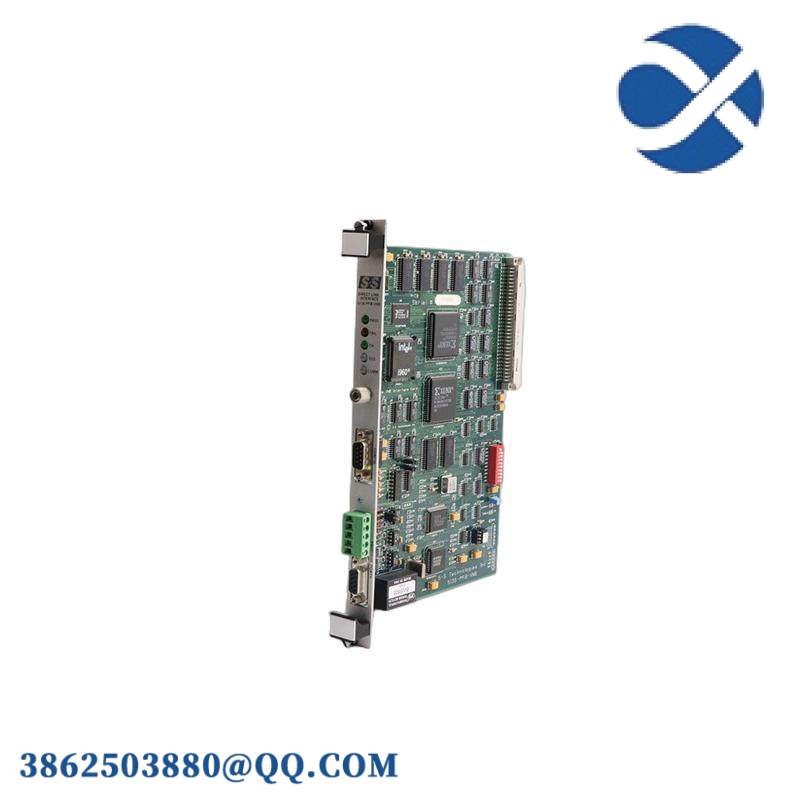

TRICONEX 3805H

TRICONEX 3805H

Product Description

The TRICONEX 3805H is a high-performance analog output module designed for industrial automation and safety-critical applications. It is part of the Triconex Safety Instrumented System (SIS) and is known for its high reliability, precision, and flexibility. This module is widely used in industries such as oil and gas, chemical processing, power generation, and steel manufacturing.

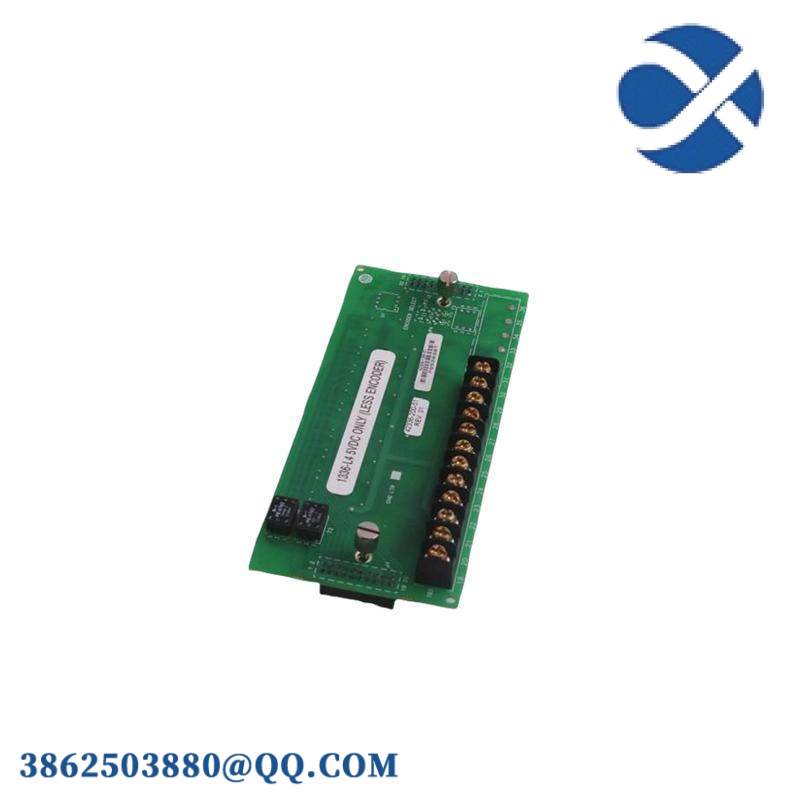

Product Parameters

-

Output Current Range: 4-20 mA (+6% overrange)

-

Resolution: 12 bits

-

Output Precision: <0.25% within the 4-20 mA range

-

Temperature Range: 0°C to 60°C (32°F to 140°F)

-

Number of Channels: 8 analog output channels

-

Redundancy Architecture: Triple Modular Redundancy (TMR)

-

Dimensions: 200 mm x 150 mm x 50 mm

-

Weight: Approximately 2 kg

Product Specifications

-

Output Type: Analog output (4-20 mA)

-

Current Loop: DC coupling

-

Safety Rating: Up to SIL 3

-

Communication Protocols: Compatible with Ethernet, Modbus, and TCP/IP

-

Certifications: TUV, UL, CE

Series

The TRICONEX 3805H belongs to the Triconex Safety Instrumented System (SIS) series, which is designed for high-reliability and safety-critical applications in industrial settings.

Features

-

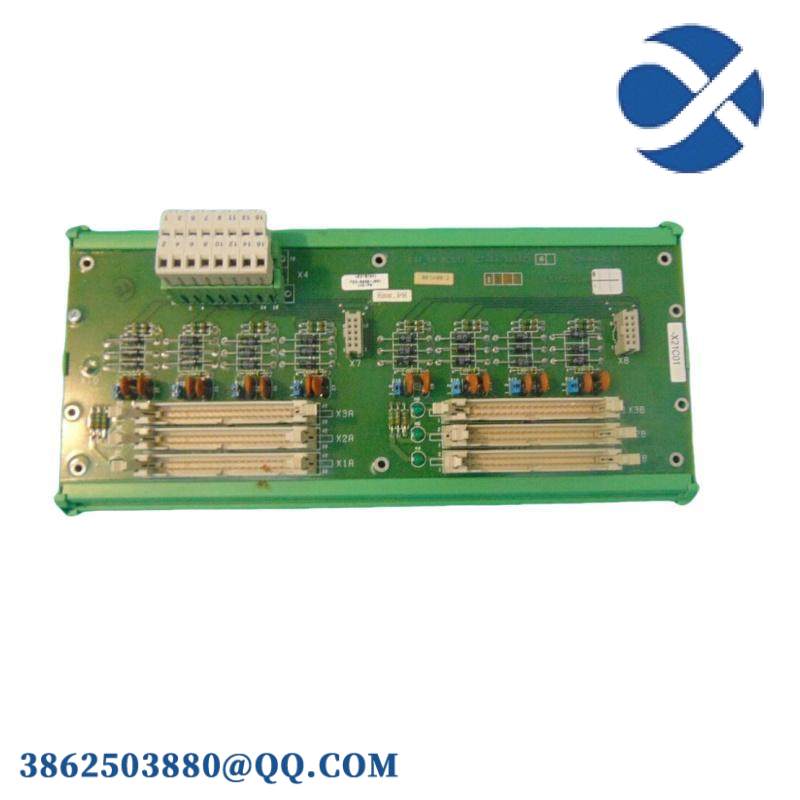

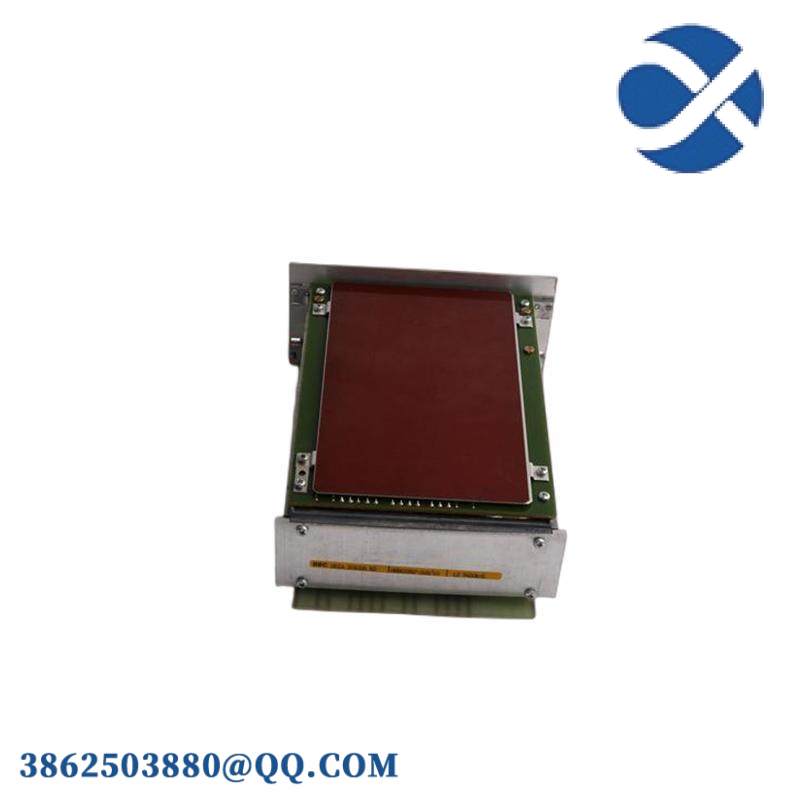

High Reliability: Part of the Invensys Triple Modular Redundancy (TMR) series, ensuring high reliability, availability, maintainability, and safety.

-

Modular Design: Flexible configuration to support various input signal types and output control methods.

-

Self-Diagnostics and Fault Tolerance: Capable of quickly locating and resolving issues, enhancing system stability.

-

Wide Temperature Range: Suitable for harsh industrial environments.

Functions

-

High-Precision Signal Output: Provides precise analog signal output for control systems.

-

Safety Control: Ensures safe operation in critical applications.

-

Real-Time Monitoring: Provides real-time status updates and alerts for critical parameters.

-

Fault Detection: Continuous diagnostics to detect and report module faults.

Uses

The TRICONEX 3805H is used in various applications, including:

-

Oil & Gas: Control of valves, pumps, and other equipment for safe production.

-

Power Generation: Control of inverters, motors, and other equipment to ensure grid stability.

-

Chemical Processing: Safety control of hazardous chemical production processes.

-

Metallurgy: Safety protection for blast furnaces, converters, and other equipment.

-

Nuclear Power: Control of various actuators to ensure safe operation.

Application Fields

-

Oil & Gas Industry

-

Power Generation

-

Chemical Processing

-

Metallurgy

-

Nuclear Power

-

Other Industrial Applications where high reliability and fault tolerance are critical

![]()

![]()