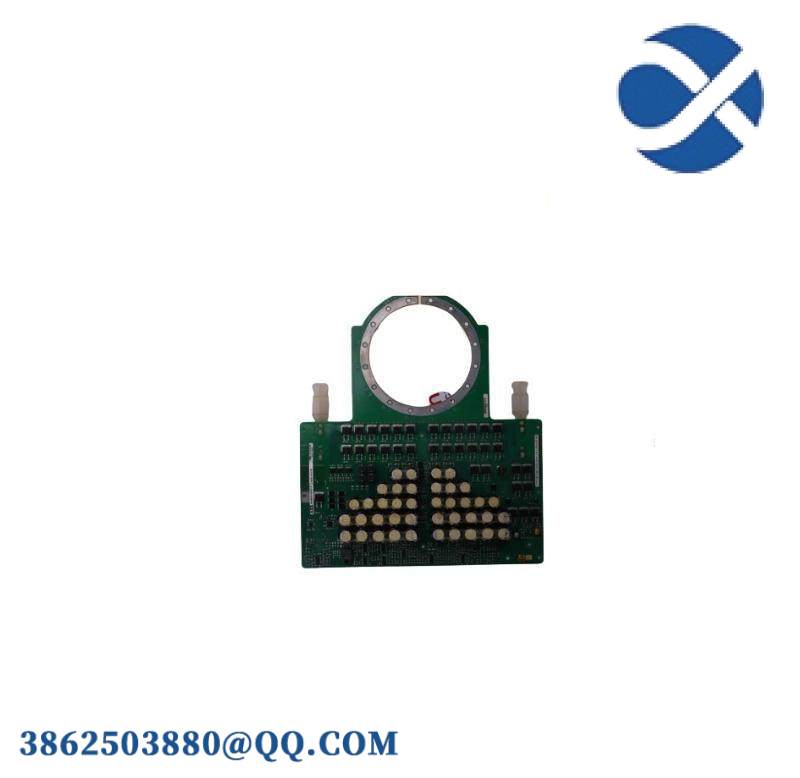

TRICONEX 3511

TRICONEX 3511 Product Description

The TRICONEX 3511 is a high-reliability digital input module designed for critical industrial control applications. It is part of the Triconex Safety Instrumented System (SIS) and is engineered to provide precise and reliable digital signal acquisition and processing.

Technical Specifications

-

Module Type: Digital Input Module

-

Input Voltage Range: 24 VDC (nominal), operating range 10-30 VDC

-

Number of Inputs: 32 channels (16 differential or 32 single-ended configurations)

-

Input Type: Dry contacts or solid-state outputs (NPN/PNP compatible), supports NAMUR proximity sensors

-

Response Time: <10 ms per channel

-

Operating Temperature: -40°C to +70°C

-

Storage Temperature: -40°C to +85°C

-

Humidity Range: 5% to 95% non-condensing

-

Safety Integrity Level: SIL 3 (IEC 61508 certified)

-

Redundancy: Triple Modular Redundancy (TMR) architecture

-

Communication Protocols: Modbus, Triconex Bus (Tristation 1131 or other Triconex controllers)

-

Power Consumption: <5W

-

Mounting: Designed for Triconex rack mounting (compatible with 3500/3700 series chassis)

-

Dimensions: Standard module dimensions (check exact specs in manual)

Series

The TRICONEX 3511 is part of the Triconex Safety Instrumented System (SIS) series, known for its high reliability and fault-tolerant design, suitable for critical industrial applications.

Key Features

-

Triple Modular Redundancy (TMR): Ensures high availability and fault tolerance by triplicating critical circuits, allowing continuous operation even in the presence of single-channel failures.

-

Isolated Input Channels: Minimizes cross-talk and electrical noise, ensuring signal integrity in harsh industrial environments.

-

Hot-Swappable Design: Allows maintenance or replacement without disrupting system operation.

-

Advanced Diagnostics: Real-time monitoring of channel health, reducing downtime through proactive fault detection.

-

Wide Operating Temperature Range: Suitable for extreme industrial conditions.

-

Safety-Certified: Meets international standards for functional safety (IEC 61508, SIL 3).

Role and Purpose

The TRICONEX 3511 serves as a crucial component in safety instrumented systems (SIS), providing reliable digital input functionality. It interfaces with various field devices to monitor and control critical processes, ensuring safety and compliance with industry standards.

Applications

The TRICONEX 3511 is widely used in:

-

Oil and Gas: Monitoring critical equipment such as valves, switches, and sensors.

-

Chemical Processing: Ensuring process safety and control.

-

Power Generation: Safety monitoring and automation.

-

Nuclear Power: Safety-critical control in nuclear facilities.

-

Manufacturing: Industrial automation and safety protection.

-

Transportation: Infrastructure safety monitoring.

Application Fields

The TRICONEX 3511 is widely used in industries that require high-precision and high-reliability automation control, such as manufacturing, energy, and water treatment. It is particularly suited for applications where continuous operation and safety are critical

TRICONEX 3511

TRICONEX 3511