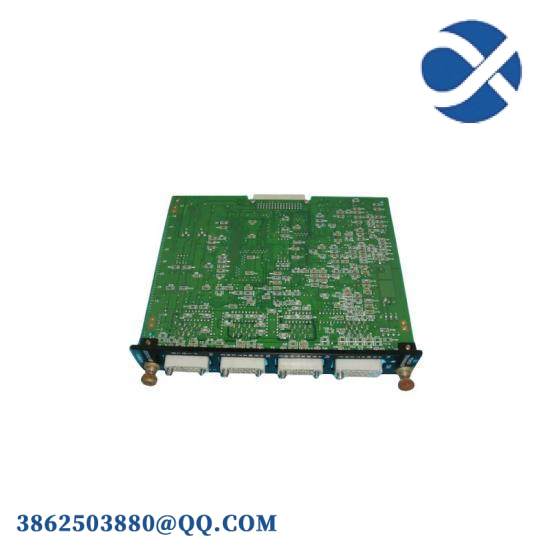

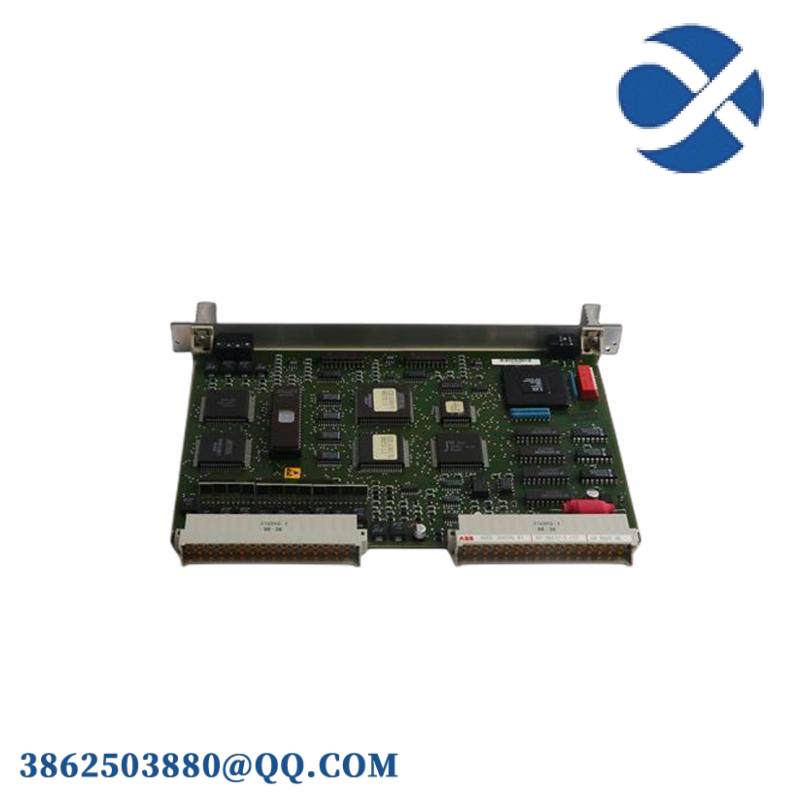

ABB INIT03

Product Description

Technical Specifications

-

Operating Voltage: 24V DC ±10%.

-

Current Consumption: ≤50 mA.

-

Response Time: 5ms.

-

Operating Temperature Range: -20°C to +60°C.

-

Communication Interface: Ethernet (10/100 Mbps), RS-485.

-

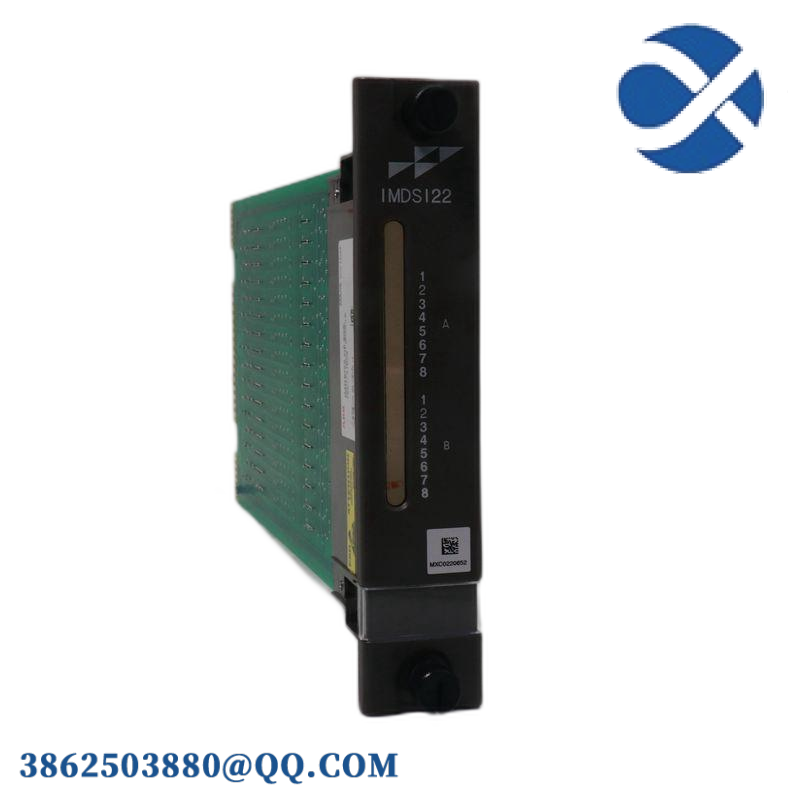

Input/Output Channels: 8 Input / 4 Output.

-

Protection Class: IP20.

-

Dimensions (W x H x D): 100mm x 80mm x 30mm.

-

Weight: Approximately 0.3 kg.

Advantages and Features

-

High Reliability: With an MTBF exceeding 100,000 hours, the INIT03 ensures prolonged operation without interruptions.

-

Advanced Diagnostics: Provides real-time status updates for quick identification and resolution of issues.

-

Energy Efficiency: Consumes low power while delivering high-performance operation, reducing energy costs.

-

Hot-Swapping Capability: Allows maintenance without powering down the entire system, minimizing operational disruptions.

-

Compatibility: Complies with international standards such as IEC 61131-2, ensuring compatibility and safety in global applications.

-

User-Friendly Interface: Simplifies setup and maintenance processes, allowing for quick configuration and adjustment.

Application Areas and Case Studies

-

Manufacturing Automation: Controlling production lines and machinery.

-

Process Control: Managing critical processes in oil, gas, and water treatment plants.

-

Power Generation: Ensuring reliable operation in power plants.

Competitive Analysis

Selection Recommendations

-

Compatibility: Ensure the module is compatible with your existing PLC system, particularly if it is part of the ABB AC500 series.

-

Environmental Conditions: Verify that the operating temperature and humidity ranges meet your application requirements.

-

Budget Considerations: The INIT03’s long lifespan and low maintenance requirements make it a cost-effective choice for projects with strict budget constraints.

Precautions

-

Installation: Ensure proper grounding during installation to prevent electrical interference.

-

Handling: Follow ABB’s safety guidelines, including wearing anti-static wristbands to avoid damage from electrostatic discharge.

-

Maintenance: Regularly inspect the module for physical damage or loose connections to maintain optimal performance.

-

Firmware Updates: When updating firmware, ensure a stable power supply to avoid corruption of the module’s software

ABB INIT03

ABB INIT03