TRICONEX D06603

TRICONEX D06603 Product Information

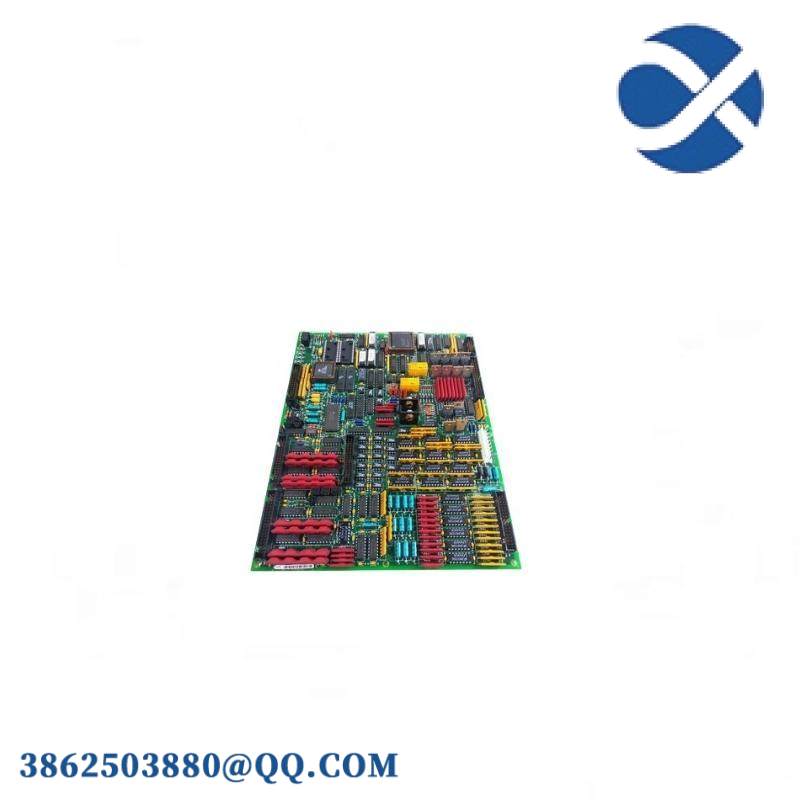

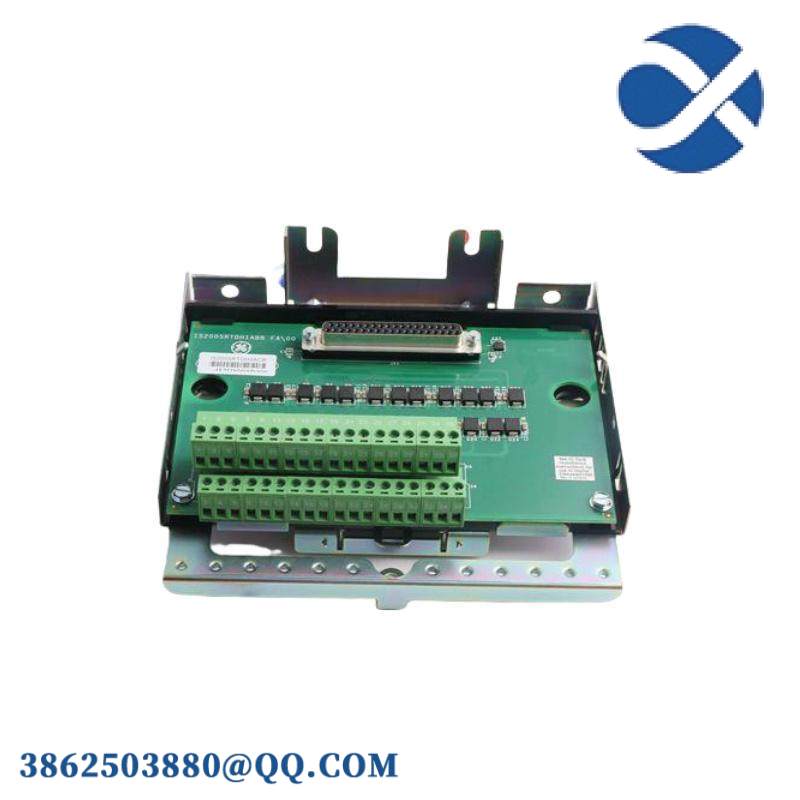

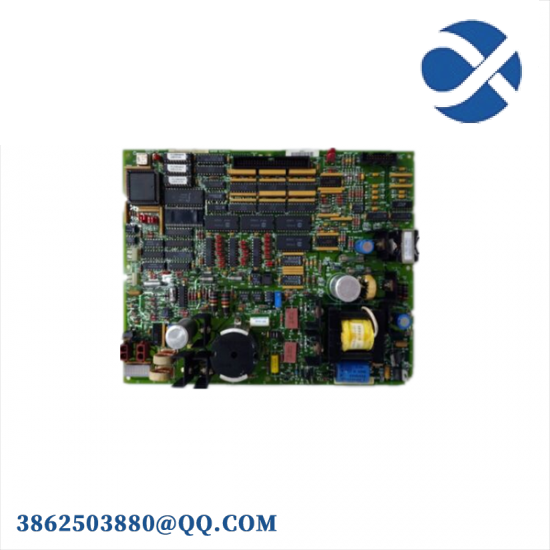

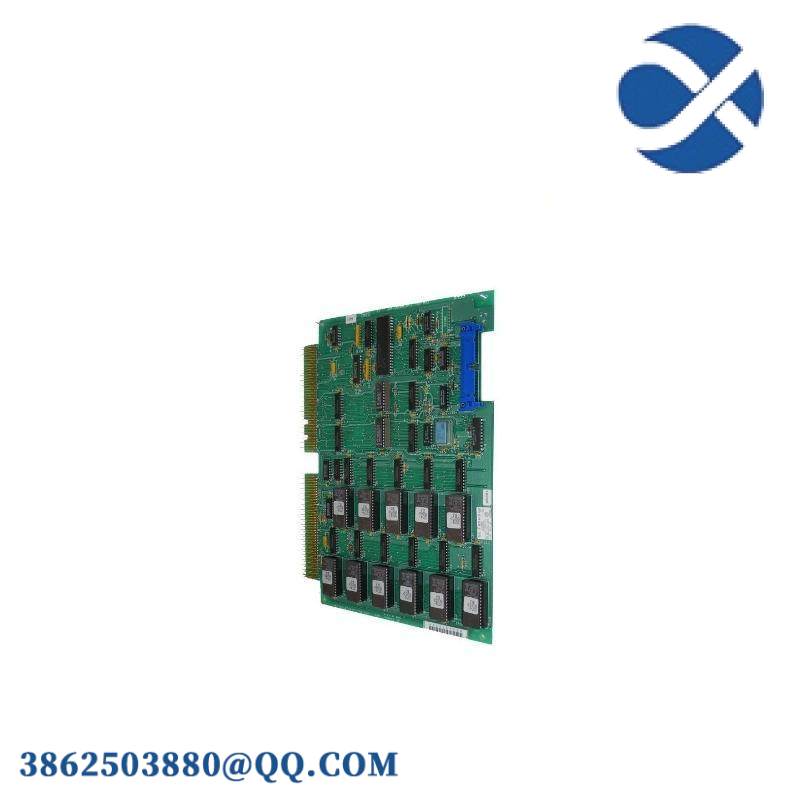

Product Description

The TRICONEX D06603 is a custom-processed industrial control module designed for high-reliability applications in various industries, including oil & gas, petrochemicals, power plants, and manufacturing. It is engineered to deliver precise performance and reliability in demanding environments.

Product Parameters & Specifications

-

Operating Voltage: V (Check datasheet for specific voltage requirements)

-

Output Frequency: kHz (Check datasheet for specific frequency range)

-

Certification: ISO 9001:2015 compliant

-

Material: High-grade aluminum alloy for robust construction

-

Dimensions: 100mm x 80mm x 20mm

-

Weight: 0.5kg

-

Operating Temperature Range: -40°C to +85°C

-

Storage Temperature Range: -40°C to +105°C

Series

The TRICONEX D06603 belongs to the TRICONEX series, which is known for its high reliability and performance in industrial automation and control systems.

Features

-

High Reliability: Triple redundancy design ensures continued operation even if one processor fails.

-

Custom Processing: Tailored to specific application requirements.

-

Fast Data Transfer: Supports dual independent read/write scanners for rapid data transmission.

-

Network Communication: Compatible with Fast Ethernet and Gigabit ports, ideal for SCADA and DCS.

-

Multi-Protocol Support: Includes Modbus TCP, OPC, and other industrial protocols.

-

User-Friendly Interface: Easy setup and maintenance procedures.

Function

The TRICONEX D06603 is designed to provide reliable data acquisition and control in industrial environments. It is ideal for applications where precision and safety are critical. It supports multiple communication protocols and can be integrated into existing industrial control systems.

Applications

The TRICONEX D06603 is widely used in:

-

Emergency Shutdown (ESD): Cuts off power during critical failures to prevent accidents.

-

Fire & Gas (F&G): Monitors and controls fire/gas leak hazards.

-

Burner Management System (BMS): Manages burner ignition/shutdown.

-

High-Integrity Pressure Protection System (HIPPS): Safeguards high-pressure equipment.

-

Turbine Monitoring & Control (TMC): Protects and regulates turbines.

-

Refineries, Steel Plants & Power Plants: Ensures automation and safety in industrial processes.

Application Fields

-

Industrial automation

-

Safety control systems

-

Oil & gas

-

Petrochemicals

-

Power generation

-

Manufacturing

![]()

![]()