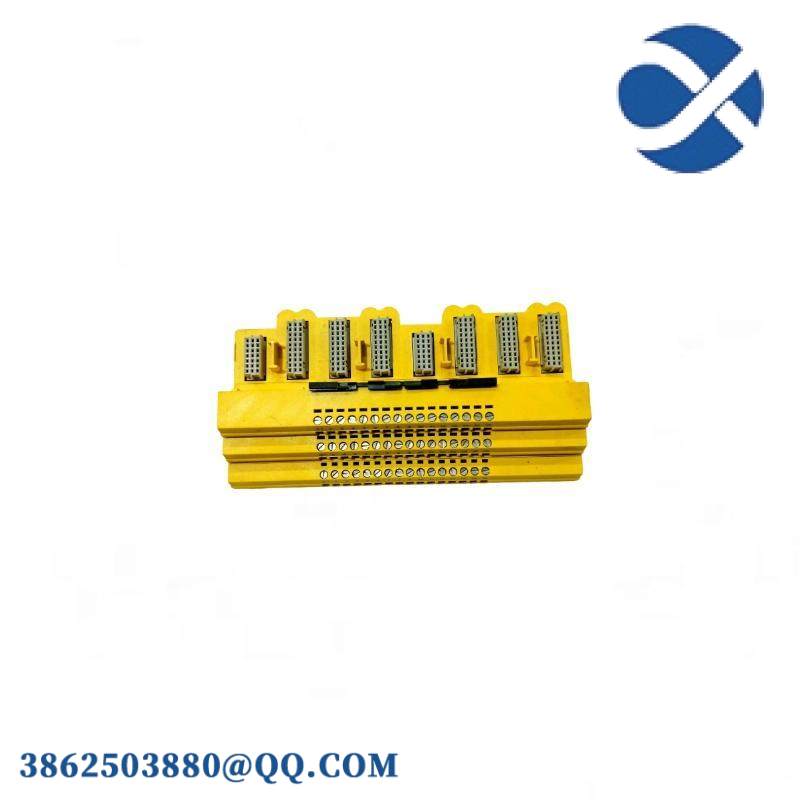

FOXBORO P0901XT

Product Description

Product Parameters & Specifications

-

Channels: 8-channel fully isolated analog input.

-

Signal Types: Supports thermocouple (TC), thermal resistor (RTD), voltage (mV/V), and current (mA).

-

Voltage/Current Measurement: 16-bit ADC resolution, nonlinearity error <0.01%.

-

Sampling Rate: Single channel 100ms update cycle, full channel scan time <1s.

-

Cold End Compensation: Built-in thermistor for automatic compensation of thermocouple cold end temperature.

-

Electrical Isolation: Channel-level isolation (≥1500V AC) and system-level isolation (common mode rejection ratio >120dB).

-

Operating Temperature Range: -40°C to +85°C.

-

Protection Level: IP20 (rack-mounted).

-

Redundancy: Supports dual redundant bus, automatic switching time <50ms.

-

Diagnostic Functions: Real-time monitoring of input disconnection, short circuit, over-range, and other faults.

Series

Features

-

High Precision Signal Acquisition: Ensures accurate measurement of temperature, pressure, flow, and level.

-

Wide Signal Compatibility: Supports multiple types of signals, including thermocouple, RTD, voltage, and current.

-

Robust Design: Built to withstand harsh industrial environments with wide temperature ranges and high reliability.

-

Redundant Communication: Ensures high reliability through redundant fieldbus communication.

-

Channel-Level Diagnostics: Provides real-time monitoring and fault detection at the channel level.

-

Easy Installation and Maintenance: Designed for easy integration and maintenance in existing systems.

Functions

-

Signal Acquisition: Collects analog signals from various sensors.

-

Signal Processing: Converts analog signals into digital signals for the control system.

-

Data Transmission: Sends processed data to the control system via the fieldbus.

-

Control Logic Execution: Executes control logic based on input signals and system requirements.

Uses

-

Process Control: Used in process control systems to monitor and control continuous processes.

-

Data Acquisition: Collects data from various sensors and devices for monitoring and control.

-

Safety Interlocking: Implements safety interlocks in critical processes.

-

Energy Optimization: Helps in optimizing energy usage in industrial processes.

Application Fields

-

Petrochemical Industry: For monitoring and control of continuous processes in refineries and chemical plants.

-

Power Generation: Used in power plants for process control and monitoring.

-

Metallurgy: For control and monitoring in metal production processes.

-

Water and Wastewater Treatment: Manages water treatment plants and environmental equipment.

-

Food and Beverage Industry: Ensures reliable signal transmission in food and beverage production processes.

-

Pharmaceutical Industry: Ensures precise control in pharmaceutical manufacturing.