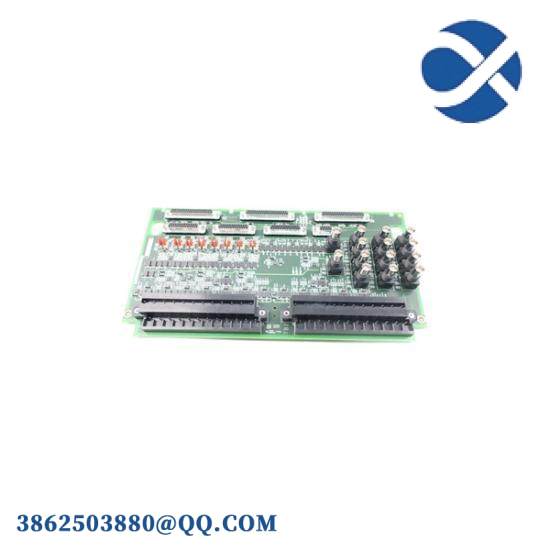

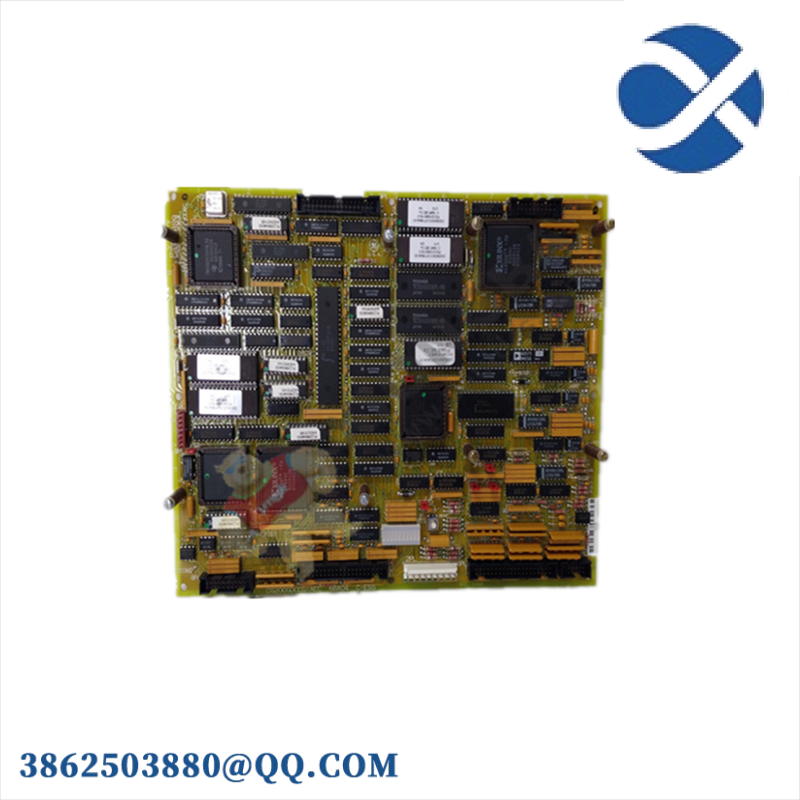

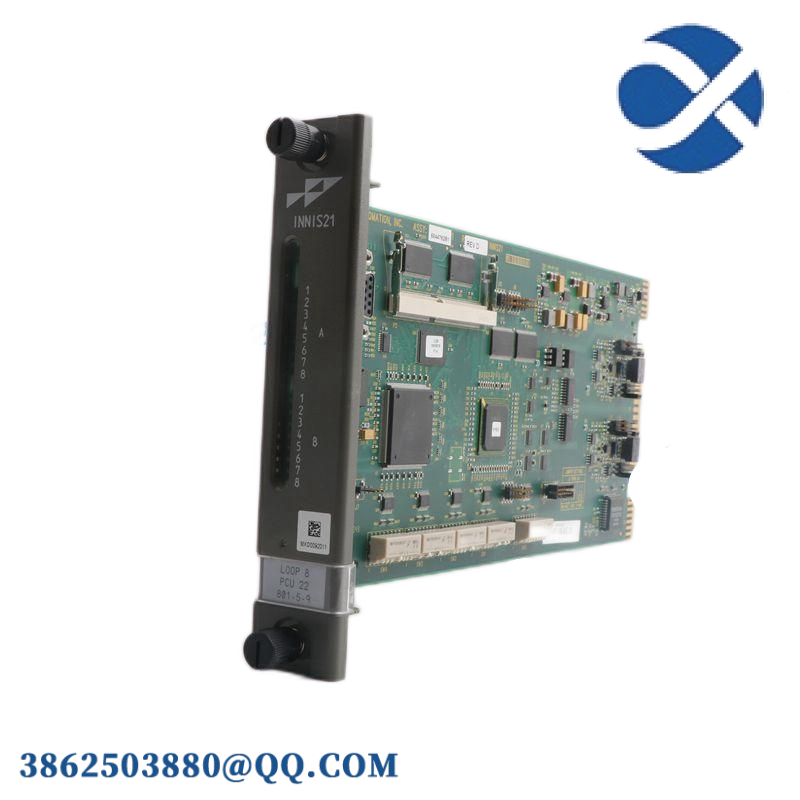

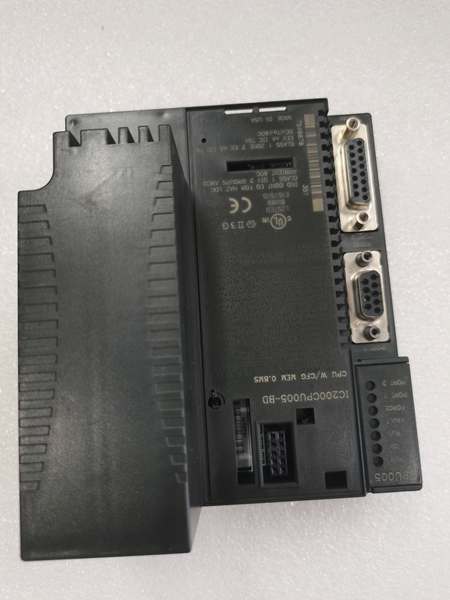

GE HE693ADC409A-22

Product Description

The GE HE693ADC409A-22 is a high-performance analog input module designed for industrial automation and control systems. It provides precise analog-to-digital signal conversion, enabling accurate data acquisition and control. This module is part of the GE Fanuc automation solutions, offering high precision and reliability in industrial environments.

Product Parameters

-

Input Type: Differential/Single-Ended Analog Inputs

-

Input Range: ±10V, 0-10V, ±20mA, 4-20mA

-

Resolution: 16-bit

-

Accuracy: ±0.1% of full scale

-

Power Supply: 24V DC

-

Module Type: Analog Input Module

-

Communication Protocol: GE Genius I/O Bus

-

Dimensions: 263 × 138 × 88mm

-

Weight: 2.35 kg

Product Specifications

-

High-Precision Conversion: 16-bit ADC for precise signal conversion.

-

Flexible Input Ranges: Supports a wide variety of input types and ranges.

-

Robust Design: Built to operate in harsh industrial environments.

-

Easy Integration: Seamlessly integrates into GE PLC systems.

-

Cost-Effective: Provides an economical solution for automation tasks requiring analog-to-digital conversion.

Series

The HE693ADC409A-22 belongs to the GE Fanuc automation solutions series, designed for industrial automation and control systems.

Features

-

High-Precision Conversion: Ensures accurate data processing with a 16-bit ADC.

-

Flexible Input Ranges: Adaptable to different industrial sensor signals.

-

Robust Design: Ensures durability and longevity in harsh environments.

-

Easy Integration: Compatible with GE PLC systems for enhanced system efficiency.

-

Cost-Effective: Offers a balance between performance and cost.

Functions

-

Signal Processing: Converts analog signals from sensors into digital data for PLC processing.

-

Data Acquisition: Collects precise data from field sensors for real-time monitoring and control.

-

Control and Monitoring: Provides precise control and monitoring for industrial processes.

Uses

-

Industrial Automation: Used in factories, assembly lines, and process control systems.

-

Measurement and Control Systems: Essential for high-precision data acquisition from field sensors.

-

Energy and Power Systems: Monitors analog signals from electrical equipment for predictive maintenance.

-

Machine Tools: Used in precision machinery where analog data is crucial for operation and control.

Application Fields

-

Manufacturing: Automobile, food & beverage industries.

-

Energy: Power generation, transmission, and distribution.

-

Chemical & Pharmaceutical: Chemical process control and pharmaceutical production.

-

Water Treatment: Water quality monitoring and control systems.

-

Transportation: Railway signal control, port automation