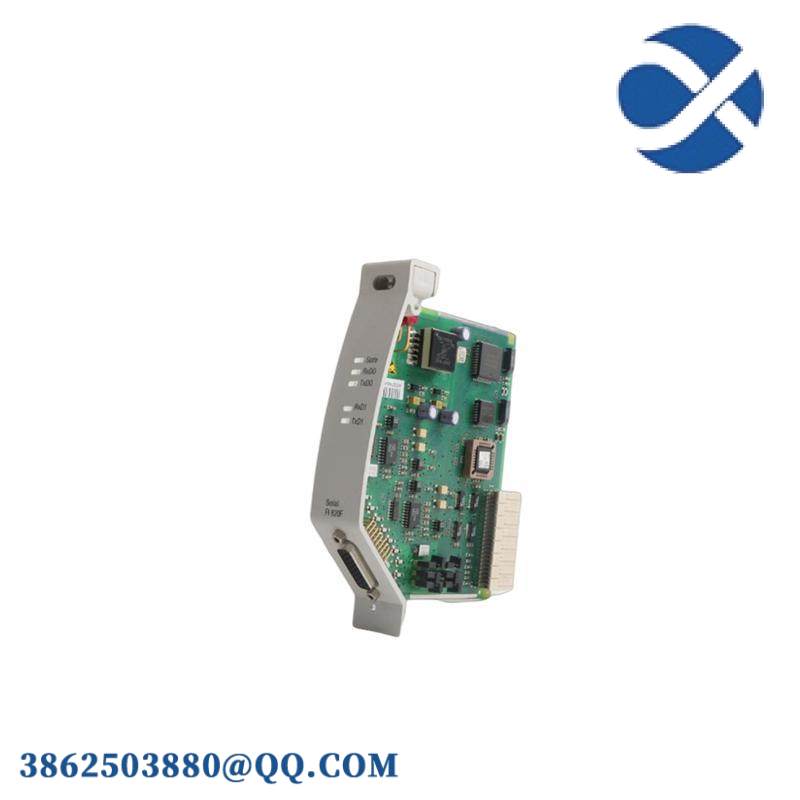

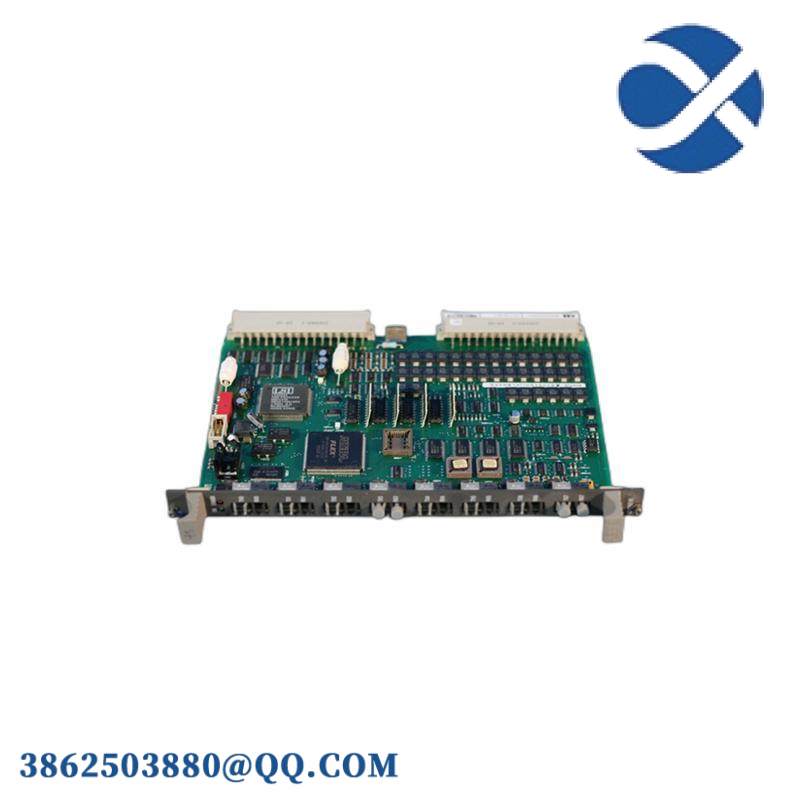

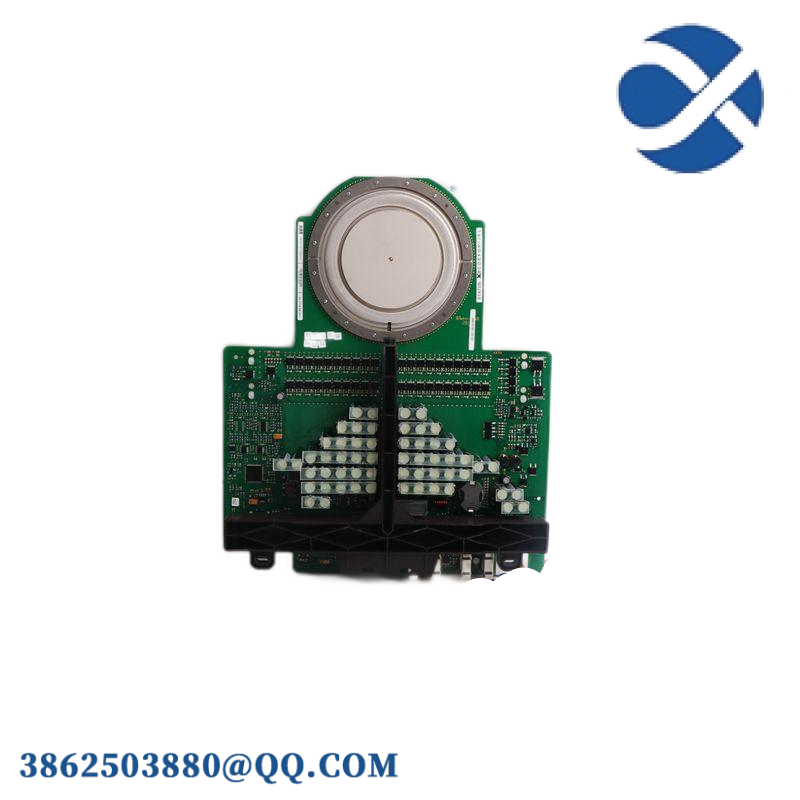

ABB FET3251C0P184C0H2

Product Description

The ABB FET3251C0P184C0H2 is a high-performance power module designed for industrial automation and control systems. It features advanced power electronics and control technology, providing high reliability and precision in power management. This module is suitable for a wide range of applications, including industrial automation, robotics, and power systems.

Product Parameters

-

Rated Voltage: 380-480V AC (some descriptions mention 220V)

-

Current Rating: 325A

-

Operating Temperature Range: -40°C to +100°C

-

Frequency Range: 50/60Hz (some descriptions mention 80kHz)

-

Protection Level: IP67

-

Output Frequency: 80kHz (some descriptions mention 24V DC)

-

Output Voltage: 24V DC (some descriptions mention 0-300 VDC)

-

Output Current: 10A (some descriptions mention 0-180 A)

-

Efficiency: ≥85% (some descriptions mention >95%)

-

Dimensions: 50mm x 100mm x 120mm

-

Weight: Approximately 1.2kg

Product Specifications

-

Low Leakage Current and High Conduction Current Capability: Ensures efficient power transfer.

-

Fast Switching Speed: Minimizes switching losses and improves system efficiency.

-

Low On Resistance and Off Resistance: Enhances overall system efficiency.

-

Zero Voltage Switching Mode: Reduces electromagnetic interference and improves reliability.

-

Short Circuit Protection Function: Ensures system safety during faults.

Series

The FET3251C0P184C0H2 belongs to the ABB industrial automation control module series, designed for high reliability and performance in complex industrial environments.

Features

-

High Performance and Reliability: Utilizes high-quality electronic components to ensure stable operation in harsh industrial conditions.

-

Module Design: Easy to install, maintain, and upgrade, enhancing system flexibility and scalability.

-

High Precision Control: Features low leakage current and high conduction current capability, suitable for high-precision control applications.

-

Multiple Communication Protocols: Supports Modbus TCP, PROFINET IO, Ethernet/IP, and other protocols for seamless integration with other systems.

-

Remote Monitoring: Supports remote monitoring and control, enhancing system intelligence.

-

Adaptability: Suitable for a variety of industrial environments, including high temperature, humidity, and dusty conditions.

-

Safety and Protection: Includes overvoltage, undervoltage, overcurrent, and short circuit protection to ensure safe operation.

Functions

-

Power Control: Manages power input and output to ensure stable operation of connected devices.

-

Signal Processing: Handles analog and digital signals for precise control and monitoring.

-

Communication: Facilitates data exchange with PLCs, HMIs, and other control systems.

-

Real-Time Monitoring: Provides real-time status updates and fault detection through LED indicators and remote logging.

Uses

-

Industrial Automation: Used in manufacturing plants for process control and monitoring.

-

Power Systems: Ensures stable operation in power plants and substations.

-

Process Control: Manages complex processes in chemical, petrochemical, and other industrial applications.

-

Energy Management: Optimizes energy use in power generation and distribution systems.

-

Robotics: Provides precise power control for robotic systems.

Application Fields

-

Manufacturing: Enhances efficiency in production lines and robotic systems.

-

Power Generation: Ensures stable operation in power plants.

-

Chemical Processing: Controls complex production processes.

-

Oil and Gas: Manages pumps and compressors in oil fields and refineries.

-

Water and Wastewater: Controls pumps and blowers in water treatment plants