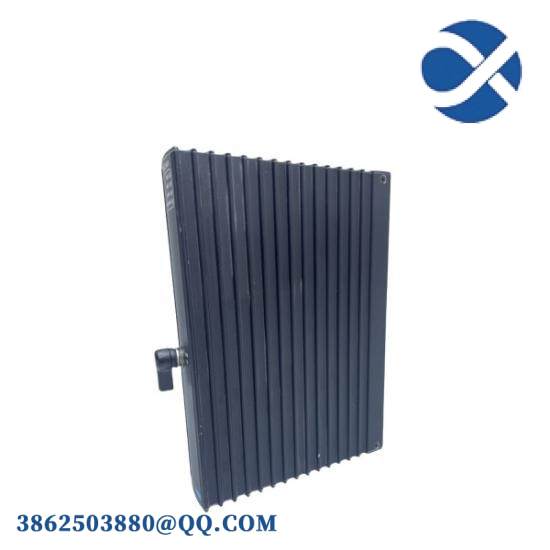

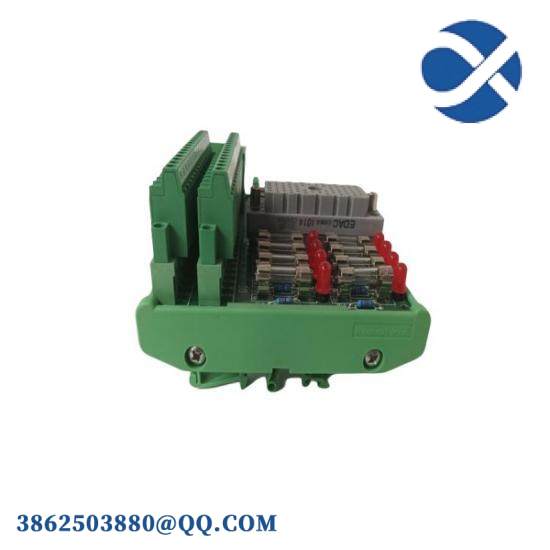

ABB CI871AK01 3BSE092693R1

Product Description

The ABB CI871AK01 3BSE092693R1 is a high-performance PROFINET IO communication interface module designed for industrial automation systems. It is part of the ABB 800xA and Advant® OCS automation platforms and is used to integrate field devices such as sensors, drives, and valves into industrial control networks.

Product Parameters

-

Model Number: CI871AK01

-

Part Number: 3BSE092693R1

-

Communication Protocol: PROFINET IO V2.3 and V2.4

-

Operating Voltage: 24V DC ±10%

-

Communication Speed: 9.6 kbps to 12 Mbps (auto-negotiation)

-

Max Stations: Up to 125 devices per segment

-

Isolation Voltage: 1500V AC (controller to field)

-

Power Consumption: 1.8W (typical)

-

Operating Temperature: -25°C to +70°C

-

Relative Humidity: 5-95% non-condensing

-

Dimensions: 195×125×75mm

-

Weight: 850g

Product Specifications

-

PROFINET IO Protocol: Supports cyclic data exchange of up to 244 bytes input/output per slave.

-

Redundancy: Dual-channel PROFIBUS DP connections with automatic switchover capability.

-

Diagnostics: Integrated web server for real-time visualization of network topology, signal quality metrics, and slave device status.

-

Future-Proof Design: Supports firmware updates without system shutdown.

Series

The CI871AK01 3BSE092693R1 belongs to the ABB Control Network Interface (CNI) series, designed for seamless integration with ABB’s 800xA distributed control system.

Features

-

High-Speed Communication: Supports up to 12 Mbps transmission speed.

-

Network Redundancy: Reduces network downtime by 90% compared to single-channel solutions.

-

Advanced Diagnostics: Real-time monitoring of network health and device status.

-

Robust Construction: Industrial-grade design with IP20 protection rating.

Functions

-

Data Exchange: Facilitates high-speed, low-latency data transmission between controllers and field devices.

-

Device Integration: Connects up to 125 devices per segment, supporting both cyclic and acyclic communication.

-

Real-Time Monitoring: Provides real-time diagnostics and network health visualization.

Uses

The CI871AK01 3BSE092693R1 is used in various industrial applications, including:

-

Power Generation: Integrating turbine control systems with field devices.

-

Oil & Gas: Connecting subsea valves and flow meters in offshore platforms.

-

Chemical Processing: Linking DCS systems to distributed I/O in batch plants.

-

Manufacturing: Facilitating real-time data exchange in automated production lines.

Application Fields

-

Power Generation: Turbine control system integration.

-

Oil & Gas: Wellhead monitoring network consolidation.

-

Pharmaceutical: Batch process equipment synchronization.

-

Water Treatment: Pump station SCADA communication.

-

Steel Plants: Coordinating data between ABB AC 800M controllers and Siemens S7-300 PLCs