Technical Principles and Innovative Values

Innovation Point 1:Servo-Grade Proportional Control

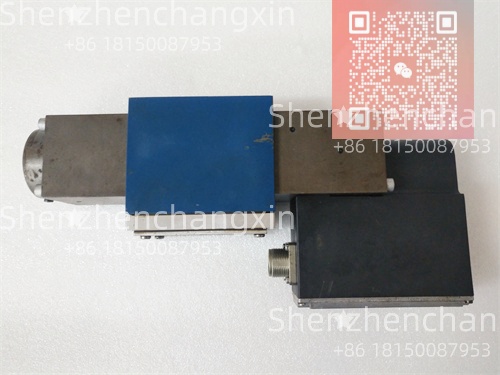

Conventional hydraulic valves use on/off solenoids,leading to jerky motion and poor repeatability.The 4WRSE10V80-32 G24K0 A1V-695 R900247749 integrates a proportional solenoid with magnetic feedback,achieving±1%linearity between electrical input(0-10V)and flow output.A U.S.aerospace component manufacturer used this valve to control a hydraulic press for titanium forming:part dimensional accuracy improved from±0.15mm to±0.02mm,reducing rework costs by 85%compared to old on/off valves.

Innovation Point 2:Anti-Pollution Spool Design

Hydraulic system failures are often caused by fluid contamination(70%of issues,per Rexroth data).This valve’s spool features a patented groove design that traps small particles(up to 25μm)and prevents them from jamming the spool.A construction equipment maker tested this in dusty mining environments:valve lifespan increased from 6 months(old models)to 3 years(4WRSE10V80-32),cutting maintenance costs by$12,000 per machine annually.

Innovation Point 3:High-Pressure&Fast Response

Heavy-industry applications(e.g.,5,000-ton presses)require both high pressure and rapid response.The valve’s 350bar continuous pressure rating handles extreme loads,while its≤10ms response time ensures precise synchronization with other system components.A Chinese steel mill used the valve to control a rolling mill’s hydraulic gap adjustment:the fast response reduced roll bounce by 60%,improving steel plate flatness from±0.5mm/m to±0.1mm/m—meeting automotive-grade material standards.

5.Application Cases and Industry Value

Case 1:CNC Machine Tool–Hydraulic Chuck Control

A Japanese CNC machining center manufacturer struggled with inconsistent workpiece clamping using outdated valves.The old valves caused±0.08mm runout in precision turning,leading to 3%part rejection and€12,000 in monthly losses.

After upgrading to REXROTH 4WRSE10V80-32 G24K0 A1V-695 R900247749 valves:

Proportional pressure control reduced chuck runout to±0.01mm,cutting rejection to 0.3%

Fast response(≤10ms)synchronized chuck clamping with spindle start,reducing cycle time by 5%

Anti-pollution design extended valve life to 2 years(vs.8 months for old valves),saving€9,600 in replacements

The engineering manager stated:“This valve’s precision has elevated our machining centers to compete in the high-end medical component market.”

Case 2:Construction Machinery–Excavator Arm Control

A Korean construction equipment maker faced operator complaints about jerky excavator arm movement,caused by slow-response valves.This led to reduced digging efficiency and increased operator fatigue.

Installing the 4WRSE10V80-32 G24K0 A1V-695 R900247749 resolved these issues:

Linear proportional control smoothed arm movement,reducing operator fatigue by 40%(per user surveys)

350bar pressure rating handled heavy loads(e.g.,10-ton concrete buckets)without performance loss

Anti-pollution design tolerated dusty job site conditions,cutting valve-related downtime by 80%

The product director commented:“This valve has become a key differentiator for our excavators—operators now prefer our machines for their smooth,precise control.”

6.Related Product Combination Solutions

REXROTH VT-VSPA1-1-1X/V0/T1 Proportional Amplifier:Converts PLC signals(0-10V)to valve-compatible current,optimizing 4WRSE10V80-32 G24K0 A1V-695 R900247749 linearity.

REXROTH DBW10B1-5X/315-6EG24N9K4 Pressure Relief Valve:Protects the 4WRSE10V80-32 from overpressure(set to 350bar),preventing damage.

REXROTH HED8OH-2X/350K14 Pressure Sensor:Monitors hydraulic pressure upstream of the 4WRSE10V80-32,enabling closed-loop control via PLC.

REXROTH ZDR6DA2-4X/210Y Pressure Reducing Valve:Supplies stable pilot pressure(210bar)to the 4WRSE10V80-32’s solenoid,ensuring consistent performance.

REXROTH Filter Element R928005873:Maintains ISO 4406 Class 16 fluid cleanliness,complementing the 4WRSE10V80-32’s anti-pollution design.

REXROTH Hydraulic Manifold 3WE6A6X/EG24N9K4:Integrates the 4WRSE10V80-32 with other valves(e.g.,check valves),simplifying system assembly.

Bosch Rexroth IndraControl VEP:PLC controller that communicates with the 4WRSE10V80-32 via CANopen,enabling centralized hydraulic system monitoring.

REXROTH Hydraulic Fluid HLP 46:Mineral oil optimized for the 4WRSE10V80-32’s seals and spool,extending valve life by 30%.

7.Installation,Maintenance,and Full-Cycle Support

Installation&Commissioning

Installing the REXROTH 4WRSE10V80-32 G24K0 A1V-695 R900247749 requires adherence to hydraulic best practices.First,verify the valve model and part number(R900247749)to ensure compatibility with your system.Flush the hydraulic circuit to ISO 4406 Class 18/16/13 cleanliness—contamination is the top cause of early valve failure.Mount the valve to an ISO 4413(CETOP 3)manifold using torque wrench(25-30 N·m for bolts)to avoid leaks.

Connect the 24V DC solenoid power supply(use shielded cable to reduce EMI)and proportional amplifier(e.g.,VT-VSPA1).Prime the hydraulic circuit to remove air,then power on the system.Use the amplifier to calibrate the valve:send 0%,50%,and 100%input signals,verifying flow rate matches specifications(use a flow meter).Adjust the amplifier’s gain if linearity deviates from±1%.

Maintenance&Fault Handling

Routine maintenance for the 4WRSE10V80-32 G24K0 A1V-695 R900247749 focuses on fluid condition and mechanical integrity.Conduct monthly checks:measure hydraulic fluid cleanliness(use a particle counter)and replace filters if contamination exceeds Class 18/16/13.Inspect valve connections for leaks—tighten bolts if needed(do not exceed 30 N·m).

If performance degrades(e.g.,slow response,erratic flow):

Check fluid temperature(should be<80℃)–overheating degrades oil viscosity and seal life.

Verify solenoid voltage(24V DC±10%)–low voltage reduces response time.

Inspect the proportional amplifier–faulty amplifiers cause non-linear flow output.

For severe issues(e.g.,valve stuck),use Rexroth’s diagnostic software(via CANopen)to read fault codes—common issues include spool jamming(resolve with fluid flushing)or solenoid failure(replace with Rexroth genuine solenoids).

Full-Cycle Support

Bosch Rexroth offers comprehensive support for the 4WRSE10V80-32 G24K0 A1V-695 R900247749 throughout its lifecycle.New valves include a 12-month warranty(extendable to 24 months with fluid analysis validation).For large-scale deployments,on-site training is provided to teach teams installation,calibration,and troubleshooting—focused on hydraulic system safety and efficiency.

Remote support is available 24/7 via Rexroth’s Technical Hotline:engineers can guide fault diagnosis,provide fluid compatibility advice,and assist with amplifier calibration.For legacy systems,Rexroth offers retrofitting services to adapt the 4WRSE10V80-32 to older hydraulic circuits,minimizing upgrade costs.Genuine spare parts(identified by R900247749)are available globally,ensuring minimal downtime for critical applications.

Whether you’re controlling industrial presses,CNC machines,or construction equipment,the REXROTH 4WRSE10V80-32 G24K0 A1V-695 R900247749 delivers the precision,durability,and reliability required for modern hydraulic control.Contact us today to discuss how this proportional valve can optimize your system’s performance and reduce long-term maintenance costs.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

Leave a comment

Your email address will not be published. Required fields are marked *