Description

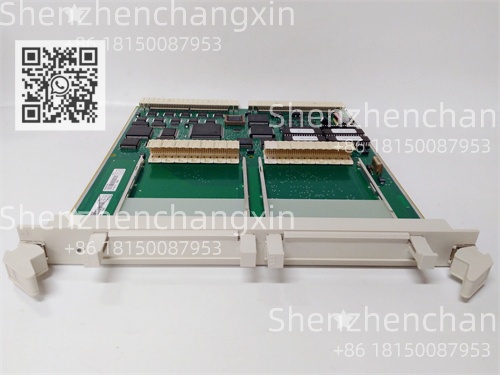

The ABB SC560 3BSE008105R1 is a high-integrity central processing unit(CPU)module designed for ABB’s Symphony®Plus distributed control system(DCS),serving as the computational core in mission-critical power generation,oil&gas,and heavy industrial applications.Engineered for extreme reliability and real-time performance,this advanced controller delivers deterministic process control with robust cybersecurity and seamless system scalability.

As a key component of the S100 and S200 I/O architectures,the SC560 3BSE008105R1 supports redundant configurations,high-speed communication,and integrated diagnostics,ensuring uninterrupted operation in harsh plant environments.

Application Scenarios

At a combined cycle power plant in the UAE,operators experienced frequent controller failures during peak load periods due to CPU overload and thermal stress in the legacy DCS.The root cause was traced to aging processors unable to handle the complex combustion tuning and emissions monitoring logic.By upgrading to the ABB SC560 3BSE008105R1 as the primary controller in the Symphony Plus system,the plant achieved stable,jitter-free control across all turbine and boiler sequences.The 3BSE008105R1’s 1 GHz processor and 1 GB RAM handled over 50,000 tags with sub-millisecond response times,while its dual Gigabit Ethernet ports enabled real-time data exchange with the plant-wide OPC UA server.The integrated firewall and secure boot functionality ensured compliance with NERC CIP standards.Since deployment,the facility has reported zero unplanned outages linked to control system failures.

Parameter

Main Parameters Value/Description

Product Model ABB SC560 3BSE008105R1(Control Processor Module)

Manufacturer ABB

Product Category Distributed Control System(DCS)CPU

Processor 1 GHz 32-bit RISC(Power Architecture or ARM-based)–High-speed execution for complex control algorithms

Memory 1 GB RAM,2 GB Flash–Ample storage for programs,historical data,and firmware

Redundancy Support Yes–Hot-standby with automatic failover in<100 ms

Communication Interfaces 2x Gigabit Ethernet(1000BASE-T),2x RS-485–High-bandwidth connectivity

Protocols Supported Modbus RTU/TCP,OPC UA,Ethernet/IP,IEC 61850(optional)–Multi-protocol interoperability

Power Supply Dual 24 V DC inputs(redundant)–Ensures continuous operation during power faults

Operating Temperature-25°C to+70°C–Suitable for high-heat control rooms and industrial environments

Installation Method 19”Rack or Cabinet Mount(Standard DCS chassis)–Compatible with Symphony Plus racks

Cybersecurity Features Secure Boot,Embedded Firewall,Role-Based Access–Protects against unauthorized access

Diagnostics Real-time health monitoring,event logging,LED status indicators–Simplifies troubleshooting

Certifications CE,UL,RoHS,IEC 61508(SIL 2 capable)–Meets global safety and functional safety standards

Technical Principles and Innovative Values

Innovation Point 1:Deterministic Real-Time Control Engine

The ABB SC560 3BSE008105R1 leverages a high-performance RISC processor and real-time operating system(RTOS)to execute control logic with microsecond-level precision.This ensures consistent scan cycles for critical applications like turbine protection,burner management,and grid synchronization.

Innovation Point 2:Dual Gigabit Ethernet with Full Redundancy

Unlike legacy controllers with 10/100 Mbps links,the SC560 3BSE008105R1 features dual Gigabit Ethernet ports supporting PRP(Parallel Redundancy Protocol)or HSR(High-availability Seamless Redundancy),enabling zero-downtime communication in fault-tolerant networks.

Innovation Point 3:Built-In Cybersecurity Hardening

The 3BSE008105R1 includes secure boot to prevent unauthorized firmware loading,an embedded firewall to filter malicious traffic,and role-based user authentication—meeting NERC CIP,ISA/IEC 62443,and other industrial cybersecurity mandates.

Innovation Point 4:Seamless Integration with Legacy ABB Systems

The SC560 is fully compatible with ABB’s Advant OCS and Symphony Harmony platforms,allowing gradual migration without system-wide re-engineering.It supports legacy I/O modules and communication protocols,protecting existing investments.

Innovation Point 5:Advanced Diagnostics and Predictive Maintenance

The ABB SC560 3BSE008105R1 continuously monitors CPU load,memory usage,temperature,and network health.Alarms are logged and can be forwarded to asset management systems,enabling predictive maintenance and reducing MTTR(Mean Time to Repair).

Application Cases and Industry Value

In a nuclear power station in South Korea,the reactor coolant system required a controller upgrade to meet stricter safety and reporting standards.The ABB SC560 3BSE008105R1 was deployed as part of a redundant DCS pair,managing over 12,000 I/O points with SIL 2 compliance.Its dual power inputs and hot-swappable design ensured continuous operation during maintenance.Over three years of operation,the system achieved 99.998%availability,and the embedded diagnostics helped identify a failing network switch before it caused a trip.

At an LNG liquefaction plant in Australia,the SC560 3BSE008105R1 was used to control cryogenic heat exchangers and emergency shutdown(ESD)sequences.Its OPC UA server provided real-time process data to the central PI System,while Modbus RTU interfaced with field transmitters.The controller’s ability to handle rapid temperature transients prevented thermal stress in pipelines,reducing maintenance costs by 35%.

Related Product Combination Solutions

ABB SC550 3BSE008104R1:Entry-level DCS CPU;can be used alongside SC560 3BSE008105R1 for distributed control in smaller subsystems.

ABB NPXP80 3BSE044998R1:Network processor module–Enhances Ethernet backbone performance for SC560-based systems.

ABB S801 I/O Modules(e.g.,3BSE020010R1):Digital and analog I/O units that connect directly to the SC560 via S100 bus.

ABB Symphony Plus HM600:Operator workstation that integrates with SC560 for HMI,alarm management,and historical trending.

ABB Redundancy Kit 3BDS008001:Hardware and firmware package enabling hot-standby redundancy for SC560 3BSE008105R1.

ABB CI854 3BSE018401R1:Profibus DP communication module–Extends connectivity to Profibus devices in SC560-controlled systems.

ABB PS501 3BSE008002R1:Power supply unit–Delivers clean 24 V DC to the SC560 and associated modules.

ABB Control Builder M:Engineering software used to configure,program,and commission the ABB SC560 3BSE008105R1 and its I/O network.

Installation,Maintenance,and Full-Cycle Support

Installing the ABB SC560 3BSE008105R1 involves mounting it in a Symphony Plus chassis(e.g.,S200 rack),connecting redundant 24 V DC power,and linking to the Ethernet backbone.Using Control Builder M,engineers can download the control strategy,configure redundancy,and test I/O mapping.The front-panel LEDs provide immediate feedback on power,run/fault,sync,and network status,simplifying commissioning.

Routine maintenance is minimal due to solid-state design.We recommend quarterly checks of terminal connections,dust filters,and backup battery(if used for clock retention).The SC560 logs system events,firmware versions,and diagnostic counters,aiding in audits and failure analysis.In redundant setups,failed units can be replaced while the system remains online.

Our technical team provides full lifecycle support,including configuration validation,cybersecurity hardening,firmware updates,and remote diagnostics.Every ABB SC560 3BSE008105R1 undergoes rigorous pre-shipment testing for power stability,communication integrity,and functional performance.With a 12-month warranty and global logistics network,we ensure fast delivery and long-term reliability.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

Leave a comment

Your email address will not be published. Required fields are marked *