Product Overview

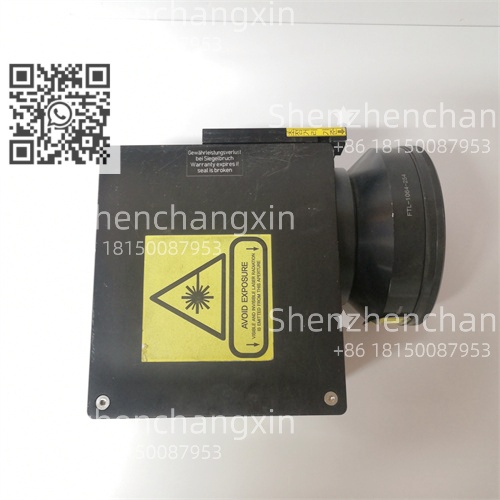

The SCANde INTELLISCANDE14-1064NM is a next-generation digital galvanometer scanner developed by SCANLAB,a global leader in laser scanning technology.Optimized for 1064nm wavelength lasers(compatible with YAG,fiber,and other laser systems),it serves as the core positioning component in precision laser processing,enabling ultra-fast and accurate beam steering for applications like marking,microfabrication,welding,and 3D printing.

Featuring fully digital control electronics,20-bit position feedback,and a compact lightweight design,this scanner bridges the performance gap between traditional galvanometers and high-end XY platforms,making it ideal for industries where micron-level precision and high throughput are critical.

Core Technical Parameters

Parameter

Specification

Product Model

SCANde INTELLISCANDE14-1064NM

Manufacturer

SCANLAB GmbH

Product Category

Digital Galvanometer Laser Scanner

Optical Wavelength

1064nm(standard);optional coatings for 355nm/10600nm

Scan Performance

Max scan angle:±20°;Max scanning speed:10m/s;Spot size:<30μm

Precision Metrics

Repeatability:<2μrad(RMS);Positioning resolution:20-bit;Nonlinearity:<0.9mrad/44°

Control Interface

SL2-100(20-bit digital);Supports Modbus/TCP&Bently Nevada protocols

Mechanical Design

Dimensions:200×200×100mm;Weight:2.5kg;Aperture:14mm

Environmental Rating

Operating temperature:-20°C to+60°C;Protection:IP20(control cabinet use)

Laser Compatibility

250W max(1064nm,100%duty cycle);Compatible with fiber/YAG/CO₂lasers

Working Principle&Innovation

1.Digital Electromagnetic Drive Mechanism

The scanner operates on the Lorentz force principle:current passing through a magnetic field generates precise torque,driving lightweight reflective mirrors to deflect laser beams.Unlike analog counterparts,its iDRIVE-based digital control electronics eliminate signal noise,reducing positioning error to<2μrad—equivalent to focusing a laser beam within a 2μm diameter at 1m working distance.

2.20-Bit Feedback&Dynamic Correction

Integrated digital encoders provide 20-bit position feedback(over 1 million measurable points per full scan angle),enabling real-time correction of thermal drift(<30μrad/K)and mechanical vibration.This ensures consistent precision even during 8-hour continuous operation,where drift remains<100μrad.

3.Multi-Protocol Connectivity

Support for Modbus/TCP and Bently Nevada protocols allows seamless integration with 3500-series control racks and factory automation systems.The SL2-100 interface enables synchronization with laser sources,reducing trigger delay to<0.2ms for high-speed sequential processing.

Application Scenarios&Case Studies

Case 1:Semiconductor Wafer Marking

A leading wafer manufacturer struggled with low throughput using analog scanners(300 wafers/hour)and inconsistent marking depth.Upgrading to INTELLISCANDE14-1064NM doubled speed to 600 wafers/hour via 10m/s scanning,while 20-bit resolution ensured marking depth variation<5μm.The Modbus/TCP interface integrated with their MES system,cutting setup time by 40%.

Case 2:Aerospace Titanium Alloy Welding

An aerospace firm required precise laser welding of 0.5mm-thick titanium parts.Legacy scanners caused weld seam deviations up to 20μm,leading to 12%rework.Deploying the SCANLAB scanner reduced deviations to<3μm via<2μrad repeatability.Its-20°C to+60°C operating range also withstood the factory’s temperature fluctuations,eliminating rework entirely.

Industry-Specific Solutions

Industry

Application

Key Advantage

Electronics

PCB micro-drilling

10m/s speed+<30μm spot size enables 10,000 holes/min with 5μm positional accuracy

Automotive

Engine part engraving

Modbus/TCP integration with robotic arms reduces cycle time by 30%

Medical Devices

Stent laser cutting

20-bit resolution ensures 1μm slit width consistency for biocompatible materials

3D Printing

Metal powder sintering

Dynamic focus synchronization with scanning reduces layer height variation to<2μm

Recommended System Combinations

SCANLAB RTC6 Control Card–Synchronizes scanner with 1064nm fiber lasers for closed-loop processing.

F-Theta Lens(f=160mm)–Expands scan field to 95×95mm while maintaining<30μm spot size.

IPG YLR-200 Fiber Laser–200W output matches scanner’s power rating for metal welding.

Bently Nevada 3500 Rack–Enables predictive maintenance via real-time scanner health monitoring.

OptoSigma Vibration Isolator–Further reduces mechanical noise for<1μrad repeatability.

Installation&Maintenance Guide

Installation

Mounting:Secure to a rigid aluminum plate(minimize vibration);maintain 50mm clearance for heat dissipation.

Calibration:Use SCANLAB’s CalibKit software to map nonlinearity,reducing error by 80%in 10 minutes.

Wiring:Separate power(24V DC)and signal cables to avoid electromagnetic interference.

Maintenance

Routine Checks:Clean mirror surfaces monthly with lens tissue(avoid alcohol);inspect connectors for corrosion.

Firmware Updates:Via USB interface to enhance protocol compatibility(e.g.,PROFINET support).

Troubleshooting:LED indicators diagnose issues(red=overcurrent;yellow=feedback error).

SCANLAB Support&Warranty

Warranty:2-year coverage for parts and labor;extended warranty available for 24/7 production lines.

Technical Service:Global network of 50+service centers provides on-site calibration within 48 hours.

Training:Free online courses on scanner tuning for microfabrication applications.

The SCANde INTELLISCANDE14-1064NM redefines precision in laser processing—whether for semiconductor manufacturing,aerospace welding,or medical device production.Contact us to customize a scanning solution with matching lenses,lasers,and control systems.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

Leave a comment

Your email address will not be published. Required fields are marked *