Product Overview

TheWoodward 8200-1301is a high-performance hydraulic actuator designed for precise control of fuel valves,steam valves,and other final control elements in turbine control systems.As part of Woodward’s renowned 8200 series hydraulic actuation products,this component represents critical execution hardware in the control loop for gas turbines,steam turbines,and other rotating equipment.TheWoodward 8200-1301actuator converts hydraulic pressure into precise mechanical motion,translating control signals from Woodward digital governors like the 5000 series into accurate positional changes of valves or other mechanical linkages.This electohydraulic interface is essential for maintaining precise speed,load,and process control in demanding industrial applications where reliability and accuracy are paramount.

Engineered for rugged industrial service,theWoodward 8200-1301features a robust construction that withstands high-pressure hydraulic systems,extreme temperatures,and challenging environmental conditions typical in power generation and industrial processing facilities.The actuator typically incorporates precision-machined components,high-quality seals,and durable materials to ensure long service life and minimal maintenance requirements.As the final element in the control loop,the performance and reliability of theWoodward 8200-1301directly impact the overall system responsiveness,stability,and safety.Its design focuses on providing linear,repeatable motion with minimal hysteresis and fast response characteristics to meet the dynamic requirements of modern turbine control systems.

The operational value of theWoodward 8200-1301lies in its ability to provide precise,reliable actuation that translates complex control algorithms into physical system adjustments.In turbine applications,this actuator helps maintain optimal combustion conditions,ensures smooth load transitions,and enables rapid response to grid frequency changes or emergency shutdown requirements.The integration of theWoodward 8200-1301within Woodward’s comprehensive control ecosystem ensures compatibility and optimized performance,contributing to overall system efficiency,reduced emissions,and extended equipment life.For operators of critical turbomachinery,this actuator represents a trusted component that delivers the mechanical motion necessary to maintain safe,efficient,and reliable operation.

Technical Specifications

Parameter Name

Parameter Value

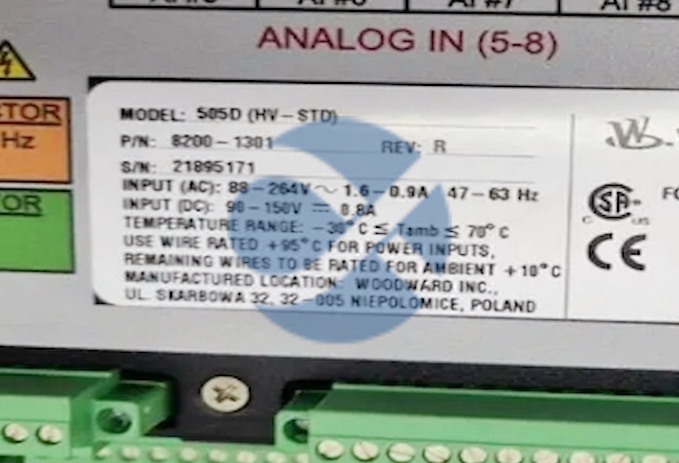

Product Model

8200-1301

Manufacturer

Woodward

Product Type

Hydraulic Actuator

Actuator Style

Linear or Rotary(model dependent)

Operating Pressure

Typically 1500-3000 psi(100-200 bar)

Stroke Length

Model specific(e.g.,2-6 inches/50-150 mm)

Position Feedback

LVDT or RVDT typically integrated

Input Signal

4-20 mA or±10 VDC from controller

Hysteresis

<0.1%of full stroke

Linearity

±0.5%of full stroke or better

Operating Temperature

-40°C to+120°C(-40°F to+250°F)

Fluid Compatibility

Mineral-based hydraulic fluids,specified fire-resistant fluids

Mounting Configuration

Flange or clevis mounting per application

Main Features and Advantages

Precision Positioning and Repeatability:TheWoodward 8200-1301is engineered to deliver exceptional positional accuracy and repeatability,which is critical for maintaining precise control over turbine parameters.The actuator typically incorporates high-quality linear variable differential transformers(LVDTs)or rotary variable differential transformers(RVDTs)that provide accurate position feedback to the control system.This closed-loop positioning capability ensures that the actuator achieves and maintains the exact position commanded by the controller,enabling fine adjustments to fuel flow,steam flow,or other process variables with minimal error.

Robust Construction for Demanding Environments:Built to withstand the challenging conditions of industrial and power generation applications,theWoodward 8200-1301features heavy-duty construction with materials selected for durability and longevity.The actuator body,piston,and other critical components are manufactured to precise tolerances using materials that resist wear,corrosion,and degradation under high pressure and temperature conditions.This robust design ensures reliable operation over extended service intervals,even in environments with vibration,contamination,and thermal cycling.

Fast Response and High Force Capability:The hydraulic design of theWoodward 8200-1301enables rapid response to control signals,allowing the actuator to quickly position valves or other final control elements in response to system demands.The hydraulic power provides substantial force capability in a compact package,making the actuator suitable for applications requiring significant force to overcome high pressure drops or mechanical resistance.This combination of speed and power ensures that the control system can effectively manage rapid transients and maintain stability during dynamic operating conditions.

Application Field

TheWoodward 8200-1301finds primary application in industries requiring precise control of rotating equipment.In power generation,it is used to control fuel valves on gas turbines and control valves on steam turbines in combined cycle plants,simple cycle peaking facilities,and cogeneration installations.In the oil and gas industry,the actuator controls fuel and compressor valves on turbines driving pipeline compressors,refinery process units,and offshore production facilities.

For industrial applications,theWoodward 8200-1301provides precise control of mechanical drive turbines in chemical plants,paper mills,and other processing facilities where reliable speed and load control are essential for process stability and efficiency.The actuator’s reliability and precision make it suitable for any application where accurate,dependable control of hydraulic-powered final elements is critical to system performance and safety.

Related Products

Woodward 5000 Series Digital Governors:Controllers that typically provide the command signals to the8200-1301actuator

Woodward 8200 Series Actuators:Other actuators in the same product family with different specifications

Woodward Hydraulic Power Units:Supply hydraulic fluid to the8200-1301actuator

Woodward ProTech Turbine Protection Systems:Safety systems that may interface with the actuator

Woodward EasyGen Control Systems:Generator control equipment often used in conjunction with turbine controls

Installation and Maintenance

Installation preparation:Proper installation of theWoodward 8200-1301requires careful planning and execution.Verify that the mounting surface is adequate for the actuator’s weight and operating forces.Ensure hydraulic connections are compatible with system pressure ratings and that piping is clean and free of contaminants.Verify electrical connections match the actuator’s requirements for power and signal interfaces.Proper alignment with the driven equipment is critical to prevent binding and premature wear.

Maintenance recommendations:Regular maintenance ensures optimal performance of theWoodward 8200-1301.Monitor for hydraulic fluid leaks and maintain proper fluid cleanliness through regular filtration.Check position feedback calibration periodically to ensure accurate positioning.Inspect mounting hardware and linkages for tightness and signs of wear.Record actuator performance trends to identify potential issues before they cause system problems.Follow Woodward’s recommended service intervals for seal replacement and internal inspection to maintain long-term reliability.

Product Guarantee

We guarantee that everyWoodward 8200-1301actuator supplied is a genuine Woodward product manufactured to the highest quality standards.Our commitment to quality ensures that each unit meets original equipment specifications for performance,reliability,and durability.We provide comprehensive technical support to assist with installation,commissioning,and troubleshooting,ensuring optimal system integration and operation.Our quality assurance processes and customer support services ensure that your investment is protected and your operational requirements are fully met with reliable,high-performance actuation solutions.

联系人:Mandy 联系电话:+8618150087953 网站:www.cxplcmro.com

Leave a comment

Your email address will not be published. Required fields are marked *