Product Overview

The Woodward 8200-226 is a high-performance magnetic pickup sensor developed by Woodward,Inc.—a global leader in control systems and sensing solutions for industrial prime movers.Specifically engineered for precise rotational speed detection,the Woodward 8200-226 serves as the”speed-sensing core”in engine,turbine,and compressor control systems,providing real-time,reliable RPM data to connected control modules(e.g.,Woodward 4-314871-1 speed control module or Woodward 2301A governor).Unlike optical or Hall-effect sensors that require external power,this magnetic pickup operates on the principle of electromagnetic induction:as a metallic target(e.g.,gear teeth,flywheel notches)rotates past the sensor’s coil,it generates an AC voltage signal proportional to the rotational speed—eliminating the need for a power supply and enhancing reliability in harsh environments.

What distinguishes the Woodward 8200-226 is its exceptional sensitivity,industrial durability,and broad compatibility.It delivers a signal output range of 0.1Vrms to 200Vrms,enabling accurate speed detection across a wide RPM spectrum(50 RPM to 20,000 RPM)—critical for applications ranging from low-speed diesel generators(1500 RPM)to high-speed gas turbines(15,000 RPM).Its rugged construction features a stainless steel housing(resistant to corrosion and impact),a hermetically sealed design(IP67 protection),and a wide operating temperature range(-40℃to+125℃),making it suitable for extreme environments:offshore oil rigs(saltwater exposure),desert power plants(high heat),and arctic mining equipment(sub-zero temperatures).Additionally,the Woodward 8200-226 is compatible with most Woodward control systems and third-party industrial controllers,via standard analog input ports,ensuring seamless integration into existing setups.This combination of precision,durability,and compatibility makes the Woodward 8200-226 an indispensable component for ensuring the safety and efficiency of industrial prime movers.

Technical Specifications

Parameter Name

Parameter Value

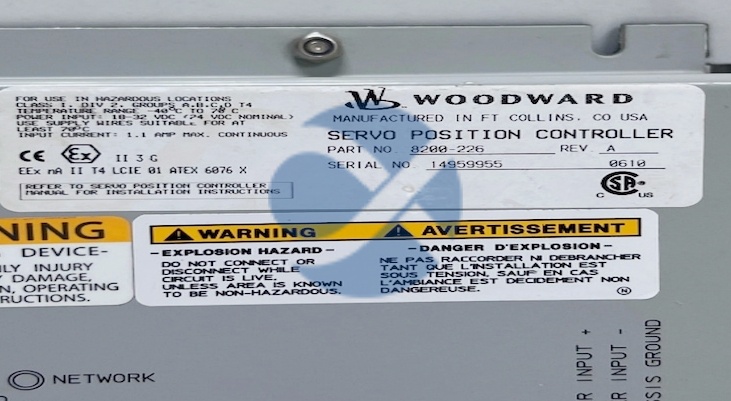

Product Model

Woodward 8200-226

Manufacturer

Woodward,Inc.

Product Type

Magnetic Pickup Sensor(Passive,Inductive Type)for Rotational Speed Detection

Compatible Control Systems

Woodward 4-314871-1,Woodward 2301A/2301D Governors,Woodward MPC-200,third-party PLCs(via analog input)

Target Compatibility

Metallic targets(steel/iron);Minimum target tooth width:1.5mm;Target air gap:0.5mm-2.0mm(optimal:1.0mm)

Speed Detection Range

50 RPM to 20,000 RPM

Output Signal

AC Voltage(Inductive);Range:0.1Vrms(at 50 RPM)to 200Vrms(at 20,000 RPM);Frequency:Proportional to rotational speed

Signal Cable

2-meter shielded twisted-pair cable(standard);Custom lengths(1m-10m)available;Cable Gauge:22 AWG(conductor),tinned copper(corrosion-resistant)

Housing Material

316 Stainless Steel(corrosion-resistant,impact-resistant);Housing Length:50mm;Housing Diameter:18mm

Seal Type

Hermetic Seal(glass-to-metal);Protection Rating:IP67(dust-tight,water-submersible up to 1m for 30 minutes)

Operating Temperature Range

-40℃to+125℃

Storage Temperature Range

-55℃to+150℃

Vibration Resistance

10-2000Hz,30g(random vibration);200g(shock,0.5ms duration)

Chemical Resistance

Resistant to oils(ASTM D471),fuels(gasoline/diesel),and saltwater(ASTM B117 salt spray test:1000 hours)

Installation Thread

1/2″-20 UNF(standard);Optional threads(M12×1.5,3/8″-16 UNC)available

Net Weight

Approximately 0.15kg(including 2m cable)

Certifications

CE(EN 61000-6-2:Industrial EMC),UL 1998(Industrial Control Equipment),RoHS 3.0

Main Features and Advantages

Passive Inductive Design for Maximum Reliability:The Woodward 8200-226 operates as a passive sensor—generating an AC voltage signal via electromagnetic induction without requiring external power.This eliminates the risk of power supply failures(a common issue with active sensors)and reduces wiring complexity(no need for power cables).For example,in a remote oilfield wellhead pump,where access to reliable power is limited,the Woodward 8200-226 continues to provide accurate speed data even if the control system’s auxiliary power fluctuates.Its passive design also extends the sensor’s service life:with no internal electronics(e.g.,amplifiers or voltage regulators)to fail,the Woodward 8200-226 achieves a mean time between failures(MTBF)of over 200,000 hours—far exceeding active sensors(typically 50,000-100,000 hours).

High Sensitivity&Wide Speed Range for Versatile Applications:With a speed detection range of 50 RPM to 20,000 RPM and output signal range of 0.1Vrms to 200Vrms,the Woodward 8200-226 adapts to diverse prime mover types.At low speeds(e.g.,150 RPM for a large diesel generator),it generates a clear 0.5Vrms signal that control modules can easily interpret—avoiding”signal dropout”issues common with less sensitive sensors.At high speeds(e.g.,18,000 RPM for a gas turbine),it produces a stable 180Vrms signal without distortion,ensuring precise speed regulation.This versatility makes it suitable for cross-industry use:from low-speed marine propulsion engines to high-speed industrial compressors.Additionally,its ability to work with minimal target air gaps(0.5mm-2.0mm)allows flexible installation,even in tight spaces(e.g.,between a turbine’s flywheel and housing).

Rugged Construction for Extreme Environments:The Woodward 8200-226 is built to withstand the harshest industrial conditions.Its 316 stainless steel housing resists corrosion from saltwater(critical for offshore applications)and chemical exposure(e.g.,oil,fuel,and hydraulic fluids in mining equipment).The hermetic glass-to-metal seal(IP67 rating)protects internal components from dust ingress and water submersion—ideal for washdown environments(e.g.,food processing plant compressors)or flood-prone areas(e.g.,coastal power plants).Its wide operating temperature range(-40℃to+125℃)ensures performance in arctic cold(where sensors with plastic housings become brittle)and high-temperature turbine enclosures(where sensitive electronics overheat).The sensor’s vibration resistance(30g random vibration)also makes it suitable for mobile equipment like mining trucks or construction machinery,where constant vibration can damage less robust sensors.

Seamless Integration with Control Ecosystems:The Woodward 8200-226 is designed for plug-and-play compatibility with Woodward’s control systems and third-party controllers.Its shielded twisted-pair cable minimizes electromagnetic interference(EMI)from nearby motors or power cables,ensuring a clean signal for control modules like the Woodward 4-314871-1.For example,in a data center’s emergency generator system,the sensor’s signal is transmitted to the 4-314871-1 module without noise,enabling the module to maintain±0.2%speed accuracy—critical for stable voltage output.The sensor’s standard 1/2″-20 UNF thread also simplifies installation:it can be mounted using common industrial tools,and optional thread sizes(M12×1.5,3/8″-16 UNC)accommodate non-standard mounting locations.For retrofits,the Woodward 8200-226 directly replaces older magnetic pickups(e.g.,Woodward 8270-1250)without modifying the control system’s wiring or configuration.

Application Field

The Woodward 8200-226 is a staple in industries relying on precise prime mover speed monitoring.In the power generation sector,it is used in diesel and gas-fired standby generators for hospitals,data centers,and manufacturing facilities.For a hospital’s 1500 RPM diesel generator,the Woodward 8200-226 detects rotational speed via the generator’s flywheel teeth and transmits a 2.5Vrms signal to the Woodward 4-314871-1 control module.The module uses this data to adjust fuel flow,ensuring the generator maintains±0.2%speed accuracy—critical for powering life-support equipment during grid outages.The sensor’s IP67 rating also protects it from dust and moisture in the generator room,ensuring year-round reliability.

In the oil and gas industry,the Woodward 8200-226 monitors the speed of wellhead pumps,drilling rig engines,and pipeline compressors.On an offshore oil rig,the sensor is mounted near the mud pump’s gearbox(exposed to saltwater spray and vibration)to detect speed(600 RPM).Its 316 stainless steel housing resists corrosion,and its passive design ensures it operates even if the rig’s auxiliary power fluctuates.The sensor’s signal is sent to a Woodward 2301A governor,which adjusts the pump’s speed to maintain consistent drilling fluid pressure—preventing wellbore collapse and ensuring safe drilling operations.

The marine industry relies on the Woodward 8200-226 for speed detection in propulsion engines and auxiliary systems.For a cargo ship’s 900 RPM main diesel engine,the sensor is installed on the engine’s crankshaft pulley,generating a 1.8Vrms signal that feeds into the ship’s propulsion control system.The system uses this data to synchronize engine speed with propeller pitch,optimizing fuel efficiency during long voyages.The sensor’s hermetic seal(IP67)protects it from water ingress in the engine room,while its wide temperature range(-40℃to+125℃)handles the extreme cold of Arctic routes and the heat of tropical waters.

In the industrial sector,the Woodward 8200-226 is used in compressors,fans,and conveyor systems.For a cement factory’s 3000 RPM air compressor,the sensor detects speed via the compressor’s impeller notches and sends a 15Vrms signal to a third-party PLC.The PLC uses this data to adjust the compressor’s load,reducing energy consumption during low-demand periods.The sensor’s vibration resistance(30g)ensures reliable performance in the factory’s high-vibration environment,while its chemical resistance protects it from cement dust and oil vapors.

Related Products

Woodward 4-314871-1:An electronic speed control module that pairs with the Woodward 8200-226.The sensor provides RPM data to the module,which adjusts fuel/air flow to maintain precise speed regulation—forming a complete speed control loop.

Woodward 2301A:A legacy mechanical governor compatible with the Woodward 8200-226.The sensor’s speed signal enhances the governor’s accuracy,making it suitable for retrofitting older engines with modern sensing capabilities.

Woodward 9907-167:A 4-20mA fuel actuator used in conjunction with the Woodward 8200-226 and a control module.The actuator adjusts fuel flow based on speed data from the sensor,ensuring optimal engine performance.

Woodward 5466-451:A 24V DC power supply module for control systems paired with the Woodward 8200-226.While the sensor is passive,the power supply ensures control modules(e.g.,4-314871-1)operate reliably.

Woodward Toolkit Software:A configuration tool for calibrating control modules connected to the Woodward 8200-226.It allows engineers to set speed thresholds,adjust signal sensitivity,and troubleshoot sensor-module communication.

Woodward 8200-226 Mounting Kit:A hardware kit including locknuts,washers,and spacers for the Woodward 8200-226.It simplifies installation on different target types(gear teeth,flywheels)and ensures optimal air gap(1.0mm).

Woodward 7009-006:A speed switch that works with the Woodward 8200-226.It uses the sensor’s signal to trigger emergency shutdowns if speed exceeds safe limits—adding a secondary safety layer for critical applications.

Woodward EMC Shielding Kit:An accessory for the Woodward 8200-226’s cable.It enhances EMI protection in high-noise environments(e.g.,near large motors)by adding a grounded copper braid shield,ensuring signal integrity.

Installation and Maintenance

Pre-Installation Preparation

Compatibility Check:Confirm the Woodward 8200-226 is compatible with the target prime mover(engine/turbine)by verifying the target type(metallic,minimum tooth width 1.5mm)and speed range(50-20,000 RPM).Ensure the connected control module(e.g.,4-314871-1)accepts AC voltage inputs(0.1Vrms-200Vrms).

Tool&Material Preparation:Gather tools including a torque wrench(5-10 N·m for mounting),feeler gauge(to measure air gap),wire strippers,and a multimeter(to test signal output).Prepare mounting hardware(locknuts,washers)and,if needed,a cable extension(shielded twisted-pair,22 AWG)for long-distance installations.

Environmental Assessment:Ensure the installation location meets the sensor’s specs:temperature(-40℃to+125℃),protection(IP67-compatible,no prolonged submersion beyond 1m),and target accessibility(sufficient space for mounting and air gap adjustment).For corrosive environments(e.g.,offshore),confirm the 316 stainless steel housing is compatible with local chemicals.

Installation Steps

Mount the Sensor:Thread the Woodward 8200-226 into the mounting bracket using the 1/2″-20 UNF thread(or optional thread).Use a torque wrench to tighten to 8 N·m(avoid over-tightening,which can damage the hermetic seal).Ensure the sensor’s tip aligns with the target(gear teeth/flywheel notches)and is perpendicular to the target’s rotational plane.

Adjust Air Gap:Use a feeler gauge to set the air gap between the sensor tip and target to 1.0mm(optimal range:0.5mm-2.0mm).Too small a gap(<0.5mm)risks contact between the sensor and target;too large a gap(>2.0mm)reduces signal strength.Lock the sensor in place with the provided locknut.

联系人:Mandy 联系电话:+8618150087953 网站:www.cxplcmro.com

Leave a comment

Your email address will not be published. Required fields are marked *